Baking food material extrusion forming equipment and use method thereof

A technology for extrusion molding and food materials, which is applied in the field of extrusion molding equipment for baked food materials, and can solve problems such as entry, adhesion, and liquefaction of water vapor when it is cold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

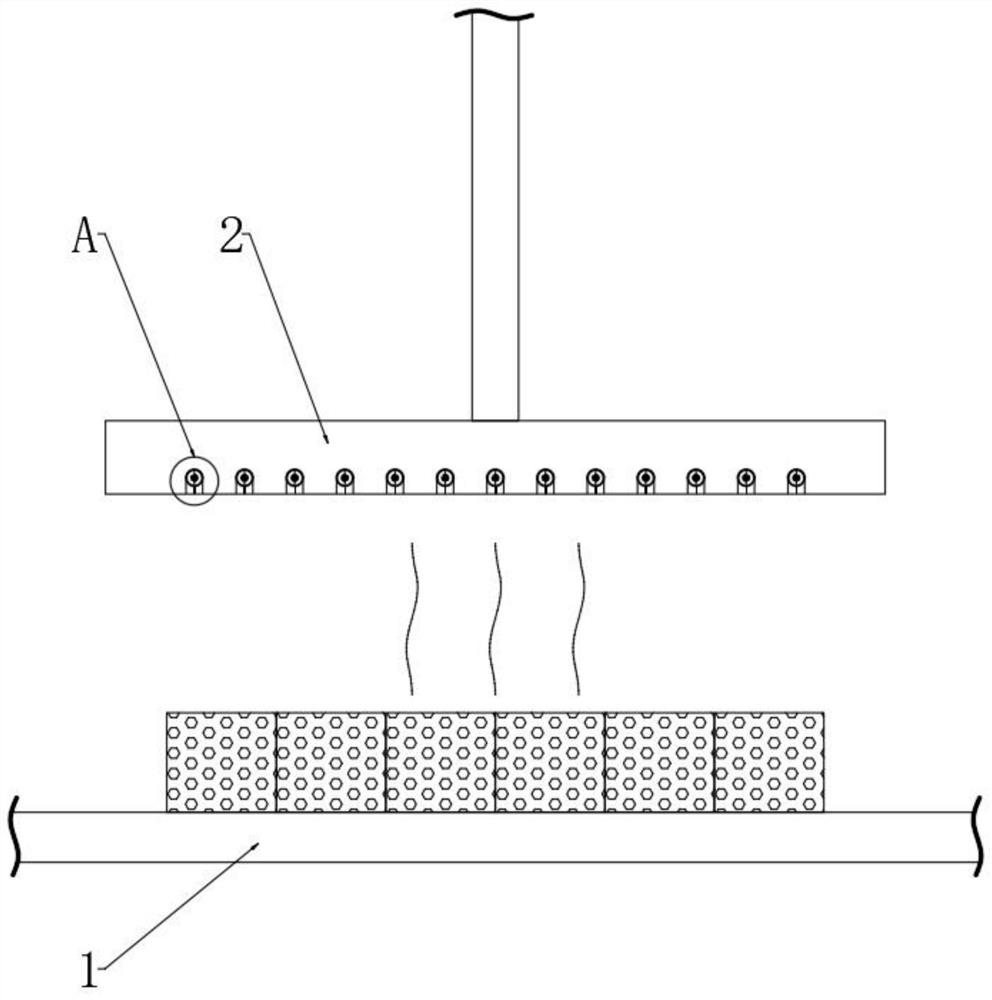

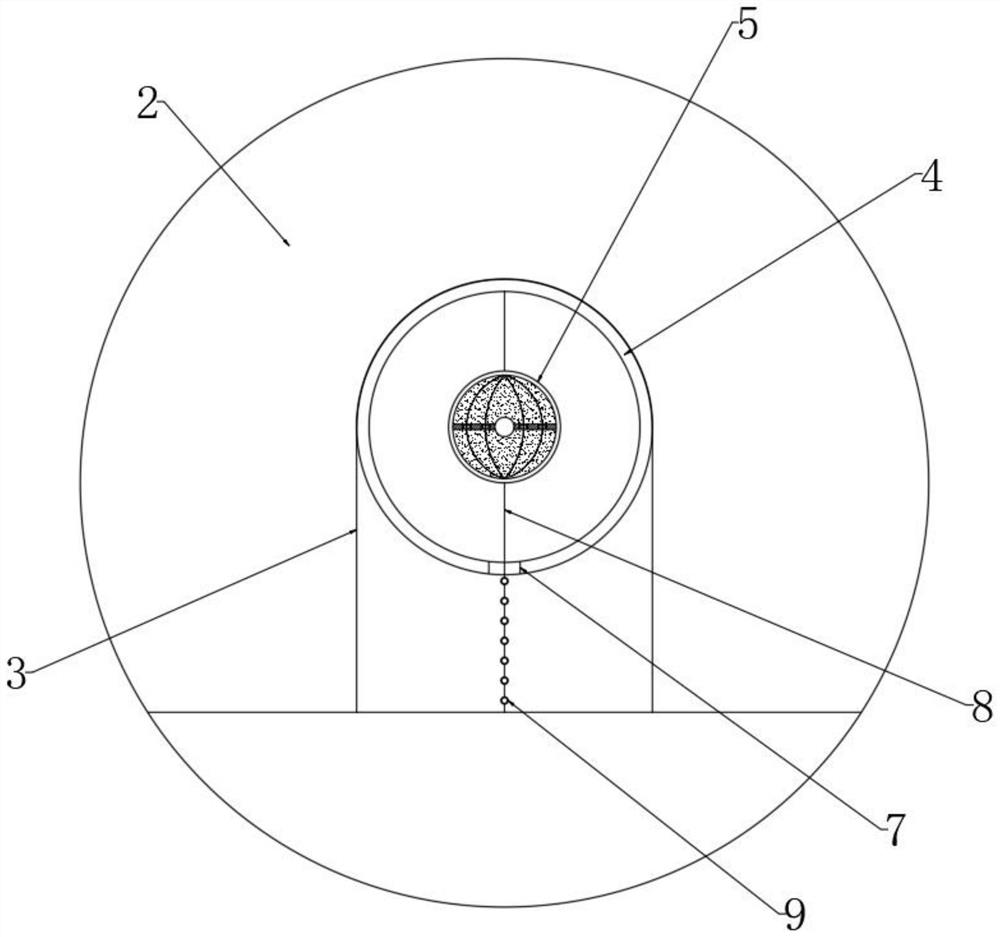

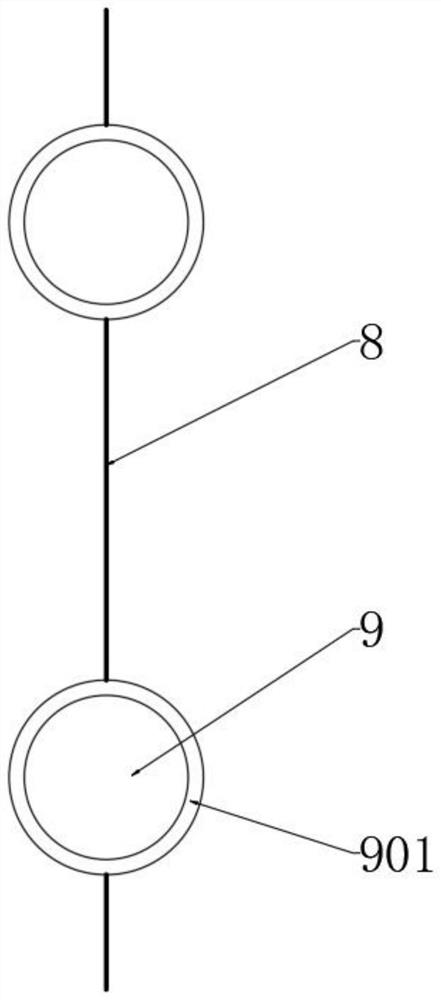

[0044] see Figure 1-3 , an extrusion molding equipment for baked ingredients, comprising an ingredient receiving plate 1 and an extruding panel 2, the upper end of the extruding panel 2 is connected to a cylinder during actual use, and the extruding panel 2 is driven to move up and down by the cylinder, extruding The pressing plate 2 is located on the upper side of the food material receiving plate 1, and the bottom end of the extruding panel 2 is dug with a plurality of evenly distributed storage grooves 3, the inner bottom of the storage grooves 3 is connected with a breathing ball frame 4, and the breathing ball frame 4 is connected with a Built-in shrinking ball 5, built-in shrinking ball 5 is provided with magnetic ball 6, exchanging through hole 7 is drilled at the bottom of the breathing ball frame 4, and the bottom end of built-in shrinking ball 5 is connected with connecting short rope 8, connecting short rope 8 The outer end is connected in series with a plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com