Cutting tool

A technology for cutting tools and shells, applied in the field of electric circular saws, can solve the problems of low motor efficiency and no consideration of circuit board heat dissipation, and achieve good heat dissipation and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Exemplary embodiments of the present invention are described below with reference to the accompanying drawings. It should be understood that these specific descriptions are only used to teach those skilled in the art how to implement the present invention, but are not intended to exhaust all possible ways of the present invention, nor are they intended to limit the scope of the present invention.

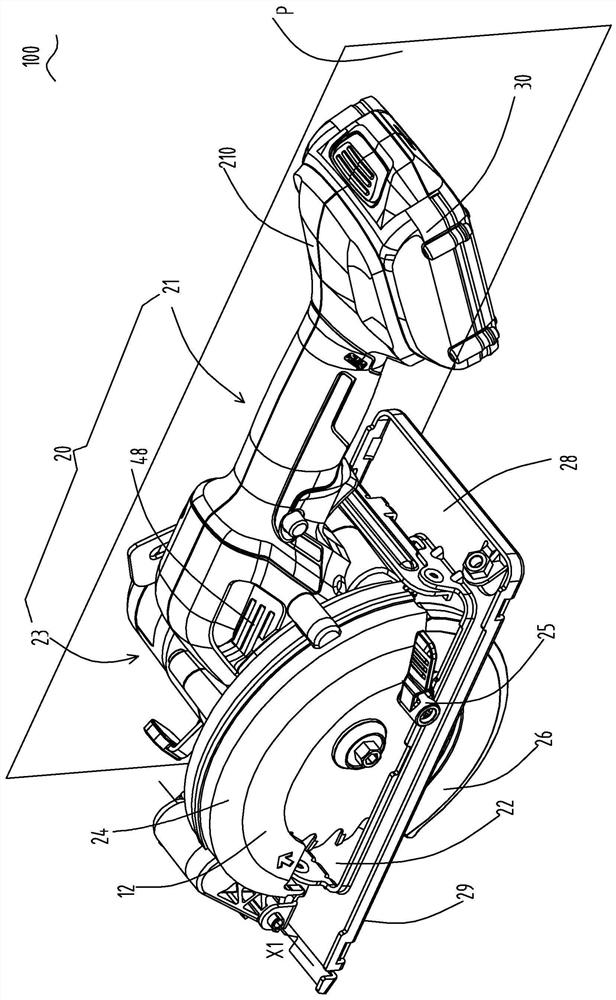

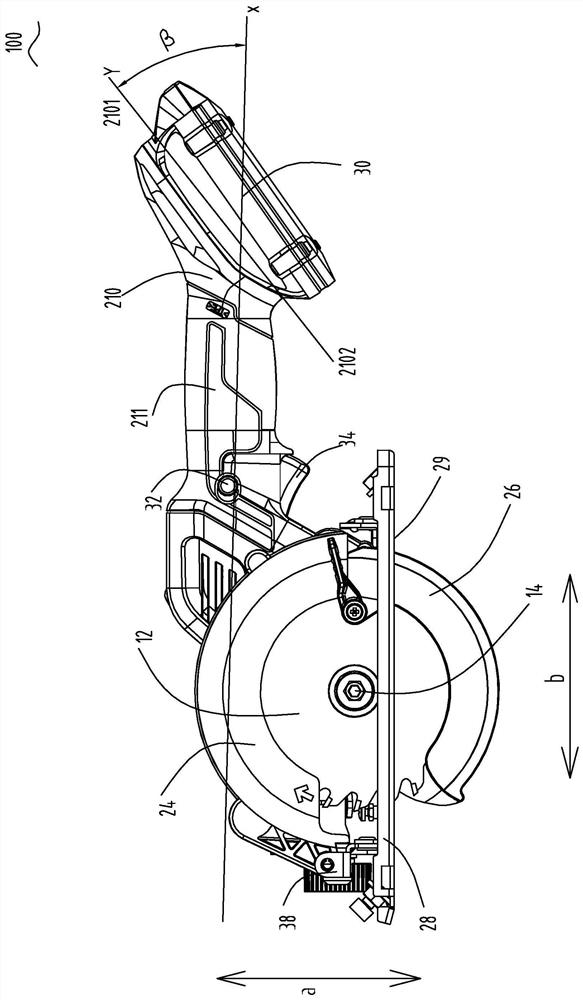

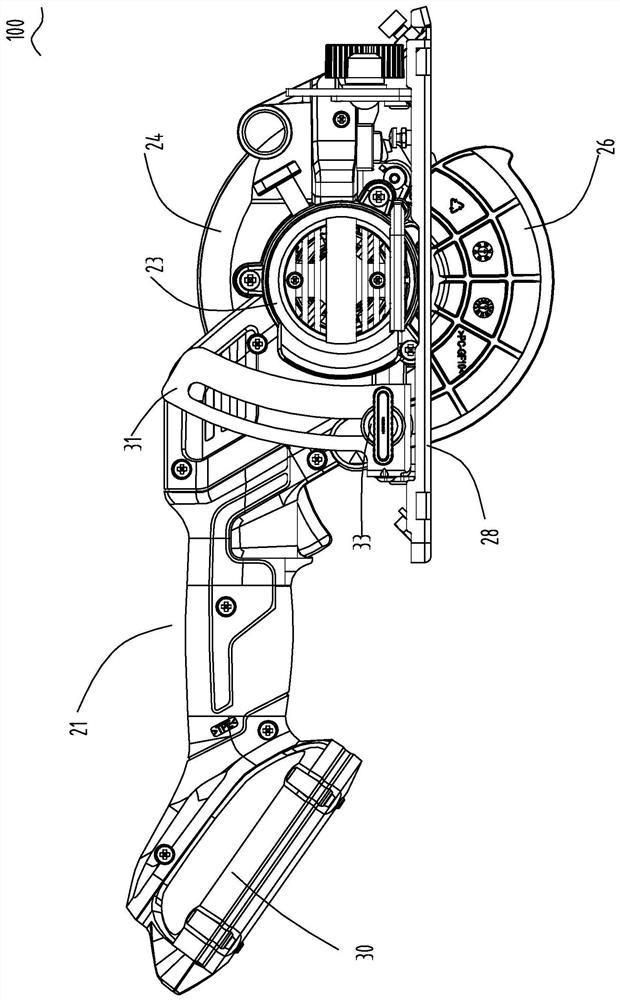

[0046] Such as Figure 1 to Figure 12 As shown, the first embodiment of the present invention provides a cutting tool 100, especially an electric circular saw, comprising: an output shaft 14 for installing a saw blade 12; a motor for driving the output shaft 14 to rotate, and the motor has a motor Shaft; the transmission device arranged between the output shaft 14 and the motor shaft is used to transmit the motion of the motor to the output shaft 14; the housing 20 is used to accommodate parts such as the motor and the transmission device; the shield assembly is attached to t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap