To-be-machined workpiece positioning method and to-be-machined workpiece positioning system

A technology of workpiece to be processed and positioning method, which is applied in the field of data capture and can solve the problems of limited edge-finding function and the inability of capacitive edge-finding function to locate the plate origin and offset angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

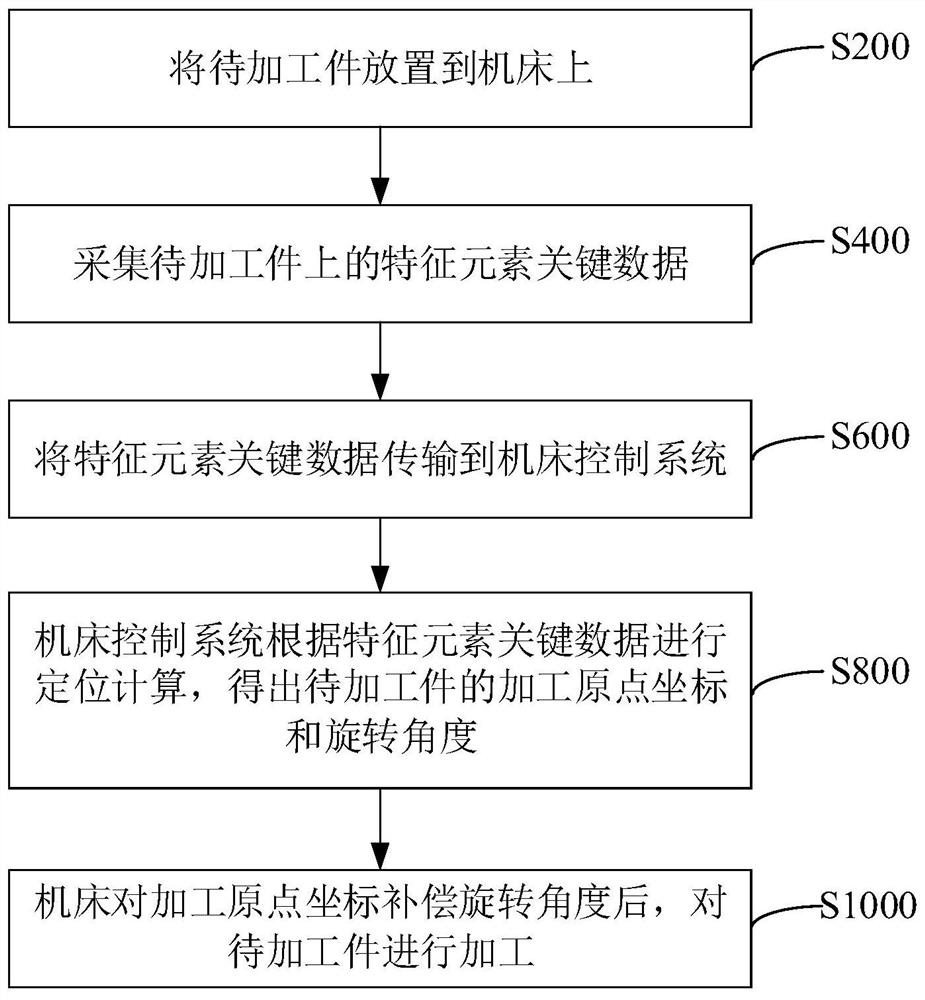

[0090] Such as figure 1 As shown, it is a schematic flow chart of the positioning method of the workpiece to be processed provided by the embodiment of the present invention, and the method specifically includes the following steps:

[0091] S200: placing the workpiece to be processed on the machine tool.

[0092] In one of the embodiments, before placing the workpiece to be processed on the machine tool, a calibration step is also included. The calibration step may specifically include obtaining the pixel equivalent in the X direction, the pixel equivalent in the Y direction, the origin offset in the X direction, and the origin offset in the Y direction. The X and Y directions are the horizontal direction of the machine tool and are perpendicular to each other.

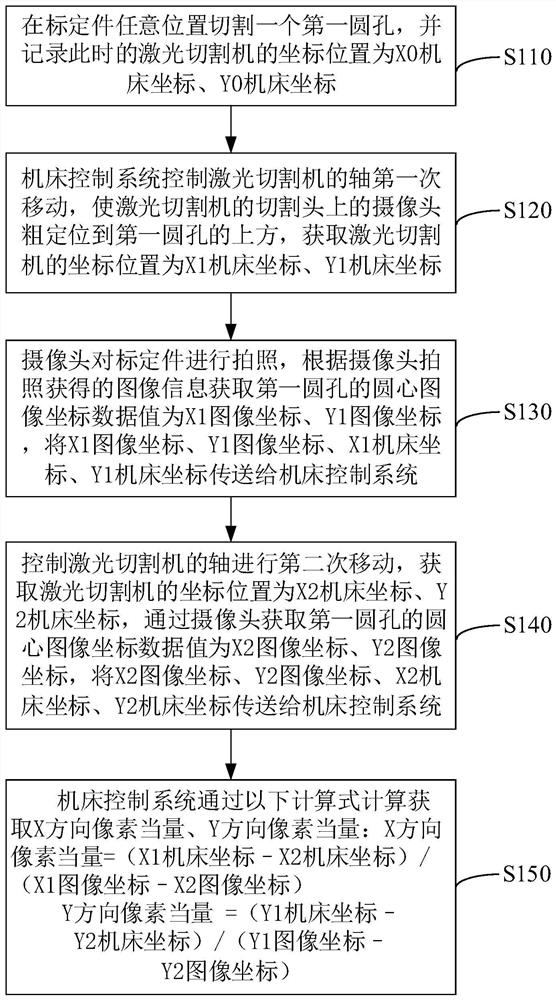

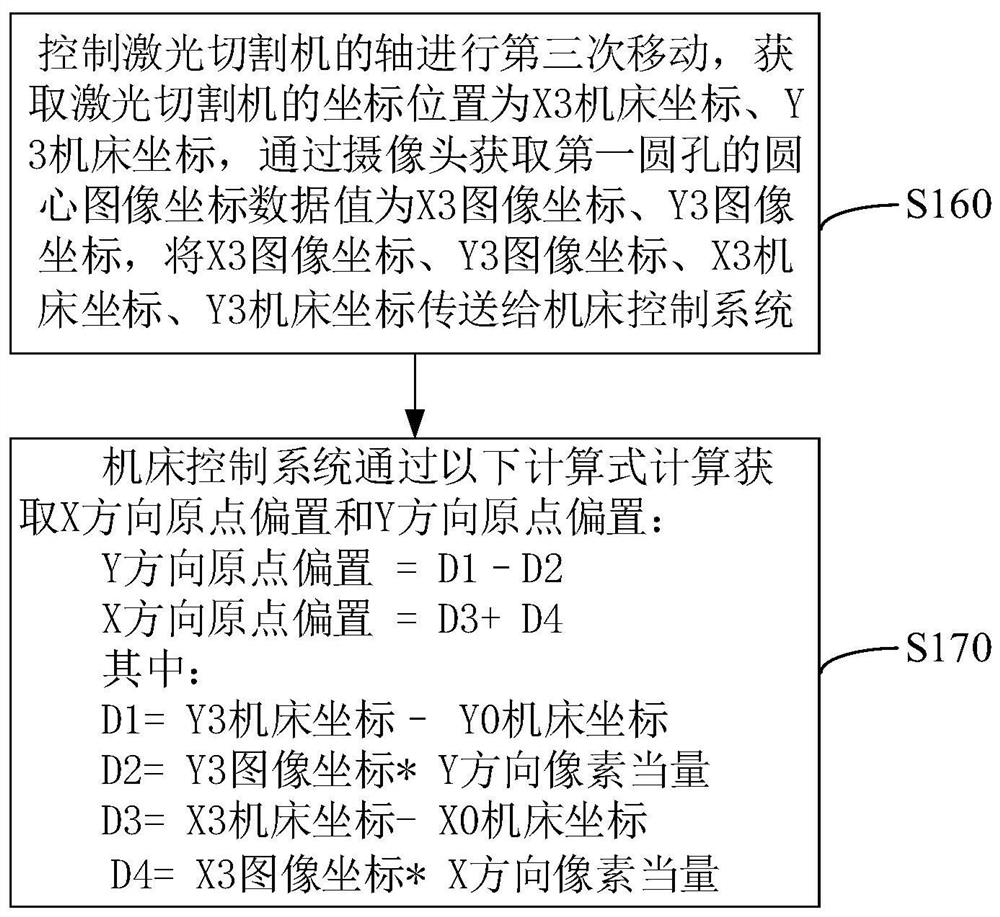

[0093] In one of the embodiments, the above-mentioned machine tool can be a laser cutting machine, such as figure 2 As shown, it is a schematic flow chart of obtaining the pixel equivalent in the X direction and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com