Flexible processing production line for retarder

A flexible processing and production line technology, applied in the field of automation, can solve the problems of high time cost and labor cost, and achieve the effect of improving efficiency, reducing update cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

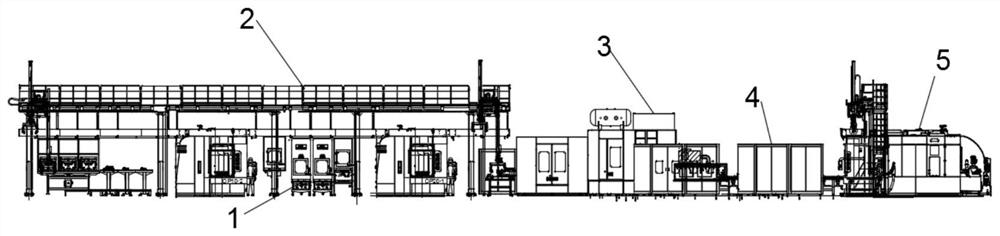

[0082] Such as figure 1 As shown, a flexible processing production line for retarders includes a processing line 1, an automatic line 2, a cleaning device 3, a leak detection device 4 and a defect detection device 5, and the processing line 1 is a discontinuous linear arrangement of processing devices and Auxiliary device, the automatic line 2 is used to transport the workpiece between the various devices of the processing line 1, the automatic line 2 is used for material transportation in the processing line 1, and the processing line 1 and the automatic line 2 are independent of each other. The cleaning device 3, the leak detection device 4 and the defect detection device 5 are sequentially connected. The cleaning device 3 is arranged at the end of the automatic line 2 and the processing line 1. The cleaning device 3 is used for deburring, cleaning, drying and temperature control of the workpiece.

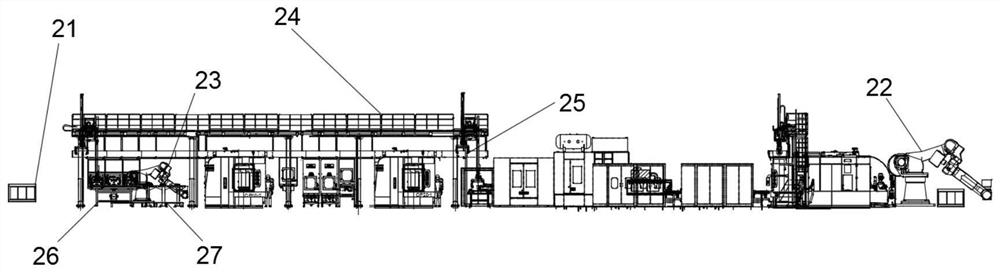

[0083] Such as figure 2As shown, the automatic line 2 includes several AGV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com