High-resilience PVC (polyvinyl chloride) foam pad and process thereof

A foam pad and high resilience technology, applied in the field of foam pads, can solve the problems of poor resilience of foam pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

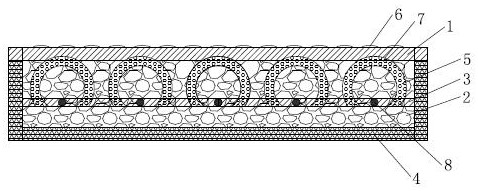

[0024] Please refer to figure 1 , figure 1 is a schematic cross-sectional view of a foam pad according to one embodiment of the present invention. A high-resilience PVC foam pad and its technology, comprising: a foam pad main body; the foam pad main body has an anti-slip and wear-resistant layer 1, a high-resilience layer 2, a skeleton layer 3, and a moisture-proof and antibacterial layer from top to bottom 4. The anti-skid and wear-resistant layer 1, the high-resilience layer 2 and the moisture-proof and antibacterial layer 4 are connected together by an adhesive, and the skeleton layer 3 is embedded in the middle and lower part of the high-resilience laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com