A kind of sponge layer toughening treatment method for air layer fabric

A treatment method and sponge layer technology, which is applied in the field of fabrics, can solve the problems of high cost and large usage of sponge, and achieve the effect of long service life, simple steps and strong resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

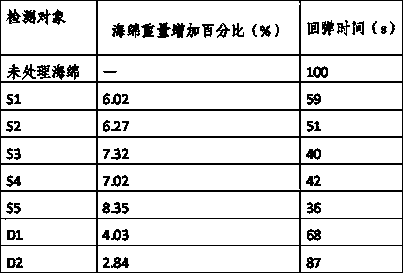

Examples

Embodiment 1

[0025] Embodiment 1 (abbreviated as S1, the following embodiments are the same) The method for toughening the air layer fabric with a sponge layer includes the following steps:

[0026] S1: Put the polyurethane sponge in the alkali pretreatment solution for immersion treatment, heat up the pretreatment for 2 hours, wash it with water, dry it, put the polyurethane sponge in the low-temperature ammonia gas for plasma treatment, apply the voltage discharge frequency of 13.75MHz, and the power of 100W , the processing time is 20s;

[0027] S2: Configure carboxylated chitosan sol treatment solution: the main components of carboxylated chitosan sol treatment solution are carboxylated chitosan, organic acid, titanium dioxide and water;

[0028] S3: immerse the polyurethane sponge in the carboxylated chitosan sol treatment solution for at least two padding treatments, raise the temperature to 40° C., keep warm for 0.5 hours, take out the polyurethane sponge, and roll off the excess so...

Embodiment 2

[0033] The difference between embodiment 2 and embodiment 1 is:

[0034] S1: Put the polyurethane sponge in the alkali pretreatment solution for immersion treatment, heat up the pretreatment for 5 hours, wash it with water, dry it, put the polyurethane sponge in the low-temperature ammonia gas for plasma treatment, apply the voltage discharge frequency of 13.75MHz, and the power of 150W , the processing time is 50s;

[0035] S2: Configure carboxylated chitosan sol treatment solution: the main components of carboxylated chitosan sol treatment solution are carboxylated chitosan, organic acid, titanium dioxide and water;

[0036] S3: soak the polyurethane sponge in the carboxylated chitosan sol treatment solution for at least two padding treatments, raise the temperature to 60° C., and keep it warm for 2.5 hours, take out the polyurethane sponge, and roll off the excess sol;

[0037] S4: washing the sponge obtained in S3 with ethanol and water in sequence, and drying at room tem...

Embodiment 3

[0041] The difference between embodiment 3 and embodiment 2 is:

[0042] S1: Put the polyurethane sponge in the alkali pretreatment solution for immersion treatment, heat up the pretreatment for 3.5 hours, wash it with water, dry it, put the polyurethane sponge in the low-temperature ammonia gas for plasma treatment, apply a voltage discharge frequency of 13.75MHz, and the power is 125W, processing time is 35s;

[0043] S2: Configure carboxylated chitosan sol treatment solution: the main components of carboxylated chitosan sol treatment solution are carboxylated chitosan, organic acid, titanium dioxide and water;

[0044] S3: soak the polyurethane sponge in the carboxylated chitosan sol treatment solution for at least two padding treatments, raise the temperature to 50°C, and keep it warm for 1.5 hours, take out the polyurethane sponge, and roll off the excess sol;

[0045] S4: washing the sponge obtained in S3 with ethanol and water in sequence, and drying at room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com