Integrated photobioreactor for efficient treatment and rapid harvesting of rare earth tail water by using flocculated microalgae

A technology of photobioreactor and reactor, which is applied in mining wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high cost, small volume of wastewater treatment, inconvenient recovery of microalgae, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

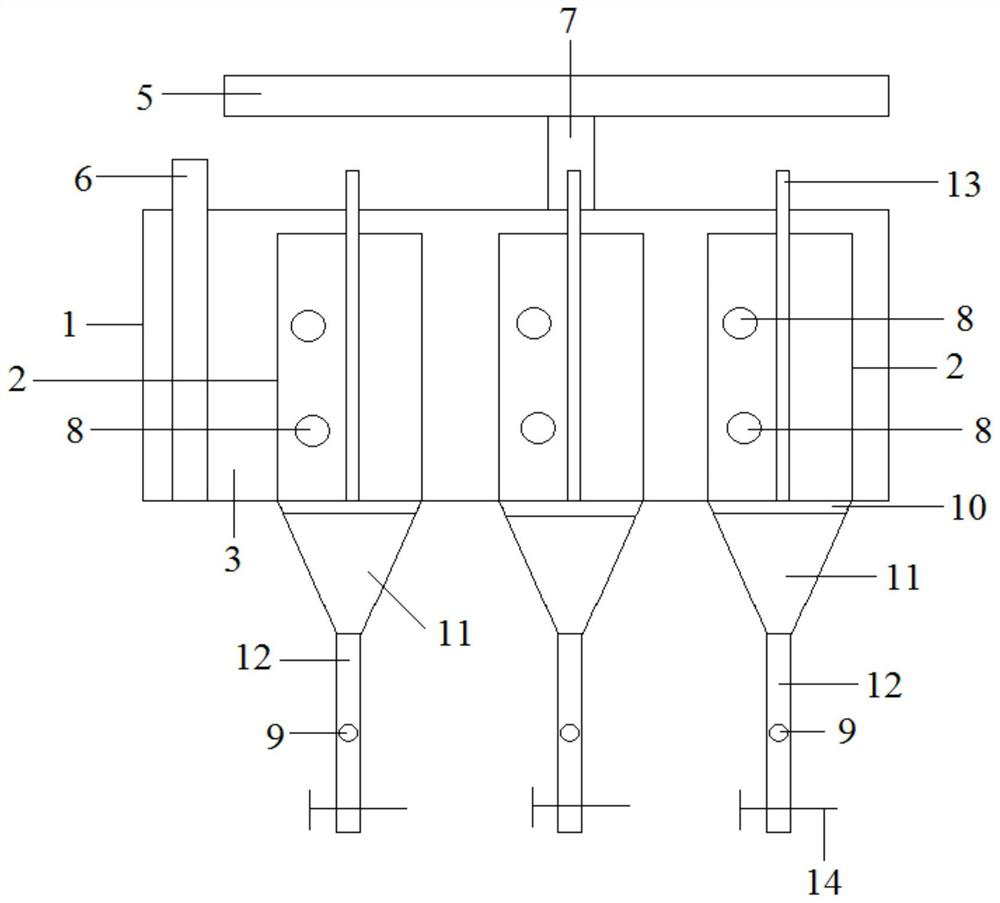

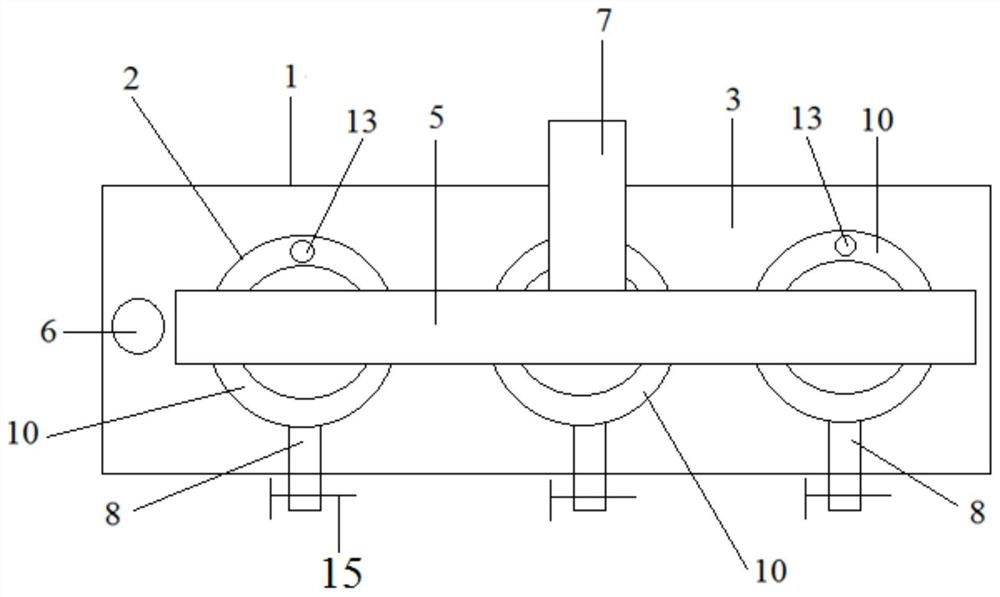

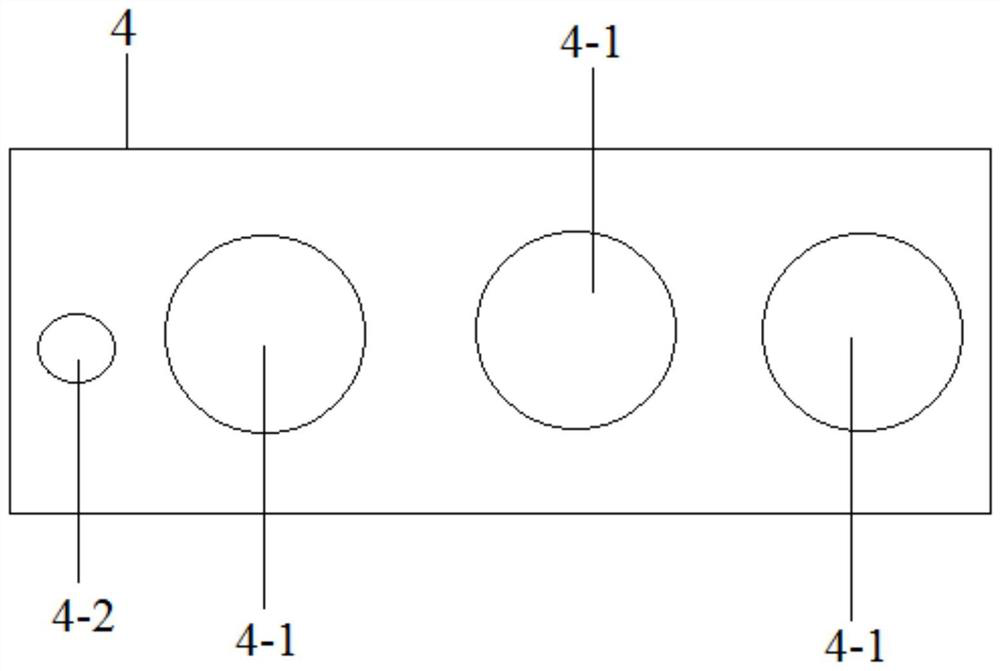

[0020] Specific implementation mode 1: This implementation mode is an integrated photobioreactor for efficient treatment and rapid harvest of rare earth tail water by flocculating microalgae, such as Figure 1-Figure 3 As shown, it is specifically composed of a reactor main body 1, a reaction chamber 2, a cover body 4, lighting equipment 5, a heating device 6, a bracket 7, a water outlet 8, a water outlet 9, an aeration ring 10, a separation device 11, and an algae liquid Composed of discharge pipe 12, intake pipe 13, first valve 14, second valve 15 and third valve;

[0021] A plurality of reaction chambers 2 are evenly fixed on the bottom surface of the inner cavity of the reactor main body 1, and a separation device 11 is arranged at the bottom of the reaction chamber 2, and the separation device 11 is arranged below the bottom surface of the reactor main body 1, and the separation device 11 is a hollow The conical structure and the larger end of the opening are at the top, ...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment differs from Embodiment 1 in that: the reaction chamber 2 is a cylindrical structure, and the ratio of height to diameter is 1:1. Others are the same as the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment is different from Embodiment 2 in that: the diameter of the opening of the reaction chamber 2 is equal to the diameter of the first through hole 4-1. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com