A kind of grain refiner of secondary aluminum alloy and its preparation method and application

A grain refiner, aluminum alloy technology, applied in the field of aluminum alloy to achieve the effects of improving casting fluidity, tensile strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

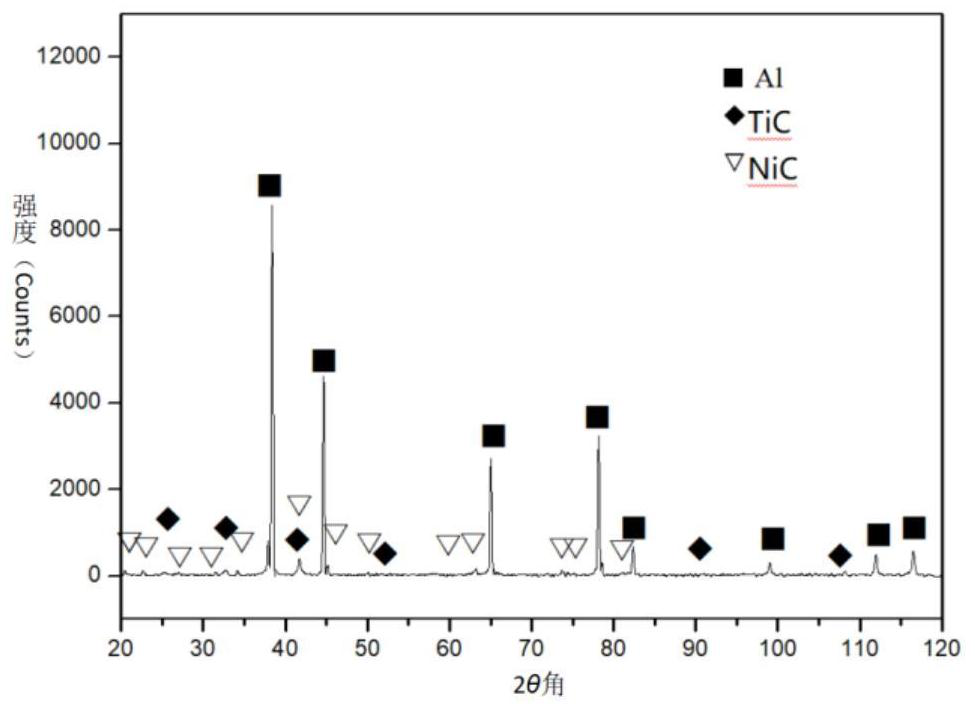

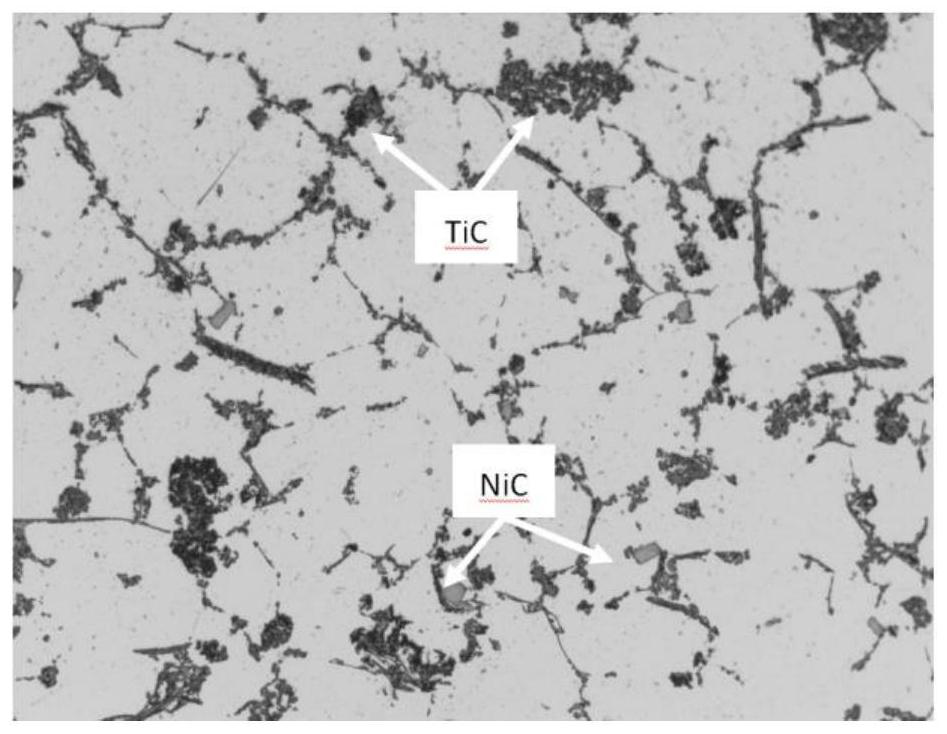

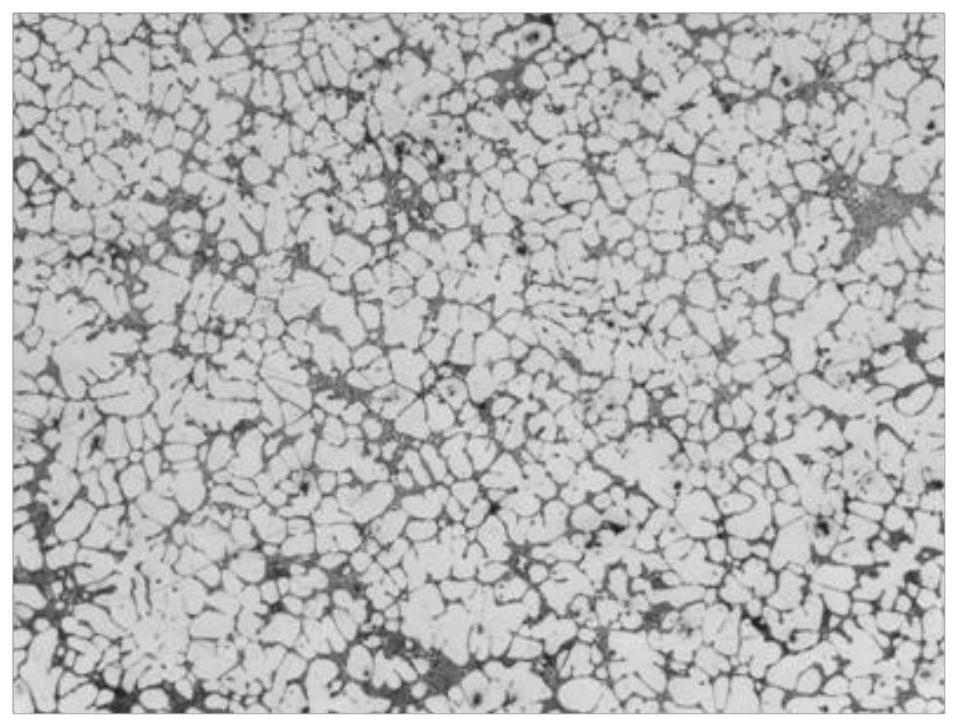

Image

Examples

preparation example Construction

[0056] The preparation method of the secondary aluminum alloy grain refiner provided by the present invention comprises the following steps:

[0057] The first step: according to the mass percentage composition of the grain refiner, aluminum ingots, titanium powder, nickel powder and carbon powder are selected as raw materials;

[0058] Step 2: Mix nickel powder and part of carbon powder and press to form a prefabricated block composed of nickel powder and carbon powder;

[0059] The third step: mixing and pressing titanium powder and carbon powder into a prefabricated block composed of titanium powder and carbon powder;

[0060] Step 4: Heat the aluminum ingot at 890-910°C to melt the molten aluminum;

[0061] Step 5: Add the prefabricated block composed of nickel powder and carbon powder into the molten aluminum and react for 10 to 15 minutes to obtain an aluminum-nickel-carbon alloy liquid;

[0062] Step 6: Add the prefabricated block composed of titanium powder and carbo...

Embodiment 1

[0087] The grain refiner of secondary aluminum alloy is composed of the following components by mass percentage: Ti 4.0%, Ni 1.0%, C0.8%, Fe 0.14%, the balance is Al and other unavoidable impurity elements, other impurity elements Individual content ≤ 0.05%, total ≤ 0.15%.

[0088] The preparation method of the grain refiner comprises the following steps in sequence:

[0089] The first step: according to the mass percentage composition of the grain refining agent, select aluminum ingot with an aluminum content of 99.7%, titanium powder with a titanium content of 99.9% and a particle size of ≤100 microns, a nickel content of 99.9% and a grain size Nickel powder with a diameter of ≤100 microns and carbon powder with a carbon content of 99.9% and a particle size of ≤50 microns are used as raw materials;

[0090] Step 2: Stir and mix nickel powder and part of carbon powder in a mixer for 1 hour at a mass ratio of 4.7:1, then put the mixed nickel powder and carbon powder into a me...

Embodiment 2

[0098] The grain refiner of secondary aluminum alloy is composed of the following components by mass percentage: Ti 4.2%, Ni 0.9%, C 0.9%, Fe 0.11%, the balance is Al and other unavoidable impurity elements, other impurity elements Individual content ≤ 0.05%, total ≤ 0.15%.

[0099] The preparation method of the grain refiner of the recycled aluminum alloy comprises the following steps:

[0100] The first step: according to the mass percentage composition of the grain refining agent, select aluminum ingot with an aluminum content of 99.85%, titanium powder with a titanium content of 99.9% and a particle size of ≤80 microns, a nickel content of 99.9% and a grain size Nickel powder with a diameter of ≤70 microns and carbon powder with a carbon content of 99.9% and a particle size of ≤30 microns are used as raw materials;

[0101] Step 2: Stir and mix nickel powder and part of carbon powder in a mixer for 2 hours at a mass ratio of 4.8:1, then put the mixed nickel powder and car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com