Titanium-aluminum base alloy with excellent room temperature ductility and casting fluidity and preparation method of titanium-aluminum base alloy

A fluidity, base alloy technology, applied in the field of superalloys, can solve the problems of poor room temperature plasticity and casting fluidity, inconvenience in the industrial casting of titanium-aluminum parts, etc., and achieve good room temperature plasticity, good casting fluidity, and huge market prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the preparation process, titanium sponge, AlCr50 alloy, pure Ni, and pure Al are used as raw materials to prepare titanium-aluminum alloy Ti-48Al-3.0Cr-0.2Ni (at%). Pre-evacuate the vacuum to 3.5Pa in the vacuum induction furnace, then fill it with argon to 60000Pa and then smelt it. When the titanium-aluminum alloy material is completely melted, continue to smelt and stir for 2 minutes, then stop the smelting, and cool the titanium-aluminum alloy ingot to room temperature; press the above Process Titanium-aluminum ingots are repeatedly smelted three times in total, and the direction of the ingot is reversed before each smelting, and then cast titanium-aluminum alloy thin-walled parts and mechanical test bars.

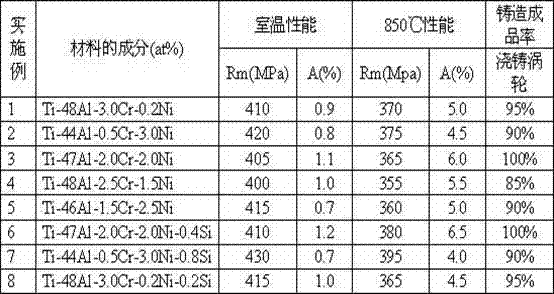

[0027] The room temperature performance and casting filling rate of titanium-aluminum alloy after testing are shown in Table 1.

Embodiment 2

[0029] In the preparation process, titanium sponge, AlCr50 alloy, pure Ni, and pure Al are used as raw materials to prepare titanium-aluminum alloy Ti-44Al-0.5Cr-3.0Ni (at%). Pre-evacuate the vacuum to 3.5Pa in the vacuum induction furnace, then fill it with argon to 60000Pa and then smelt it. When the titanium-aluminum alloy material is completely melted, continue to smelt and stir for 2 minutes, then stop the smelting, and cool the titanium-aluminum alloy ingot to room temperature; press the above Process Titanium-aluminum ingots are repeatedly smelted three times in total, and the direction of the ingot is reversed before each smelting, and then cast titanium-aluminum alloy thin-walled parts and mechanical test bars.

[0030] The room temperature performance and casting filling rate of titanium-aluminum alloy after testing are shown in Table 1.

Embodiment 3

[0032] In the preparation process, titanium sponge, AlCr50 alloy, pure Ni, and pure Al are used as raw materials to prepare titanium-aluminum alloy Ti-47Al-2.0Cr-2.0Ni (at%). Pre-evacuate the vacuum to 3.5Pa in the vacuum induction furnace, then fill it with argon to 60000Pa and then smelt it. When the titanium-aluminum alloy material is completely melted, continue to smelt and stir for 2 minutes, then stop the smelting, and cool the titanium-aluminum alloy ingot to room temperature; press the above Process Titanium-aluminum ingots are repeatedly smelted three times in total, and the direction of the ingot is reversed before each smelting, and then cast titanium-aluminum alloy thin-walled parts and mechanical test bars.

[0033] The room temperature performance and casting filling rate of titanium-aluminum alloy after testing are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com