Construction machinery and its box-type working device

A working device and box-type technology, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of improving the failure rate of working devices, the need to improve corrosion resistance, and increasing the fuel consumption of construction machinery, so as to improve the mechanical uniformity, Effects of weight reduction, excellent casting flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. Various preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

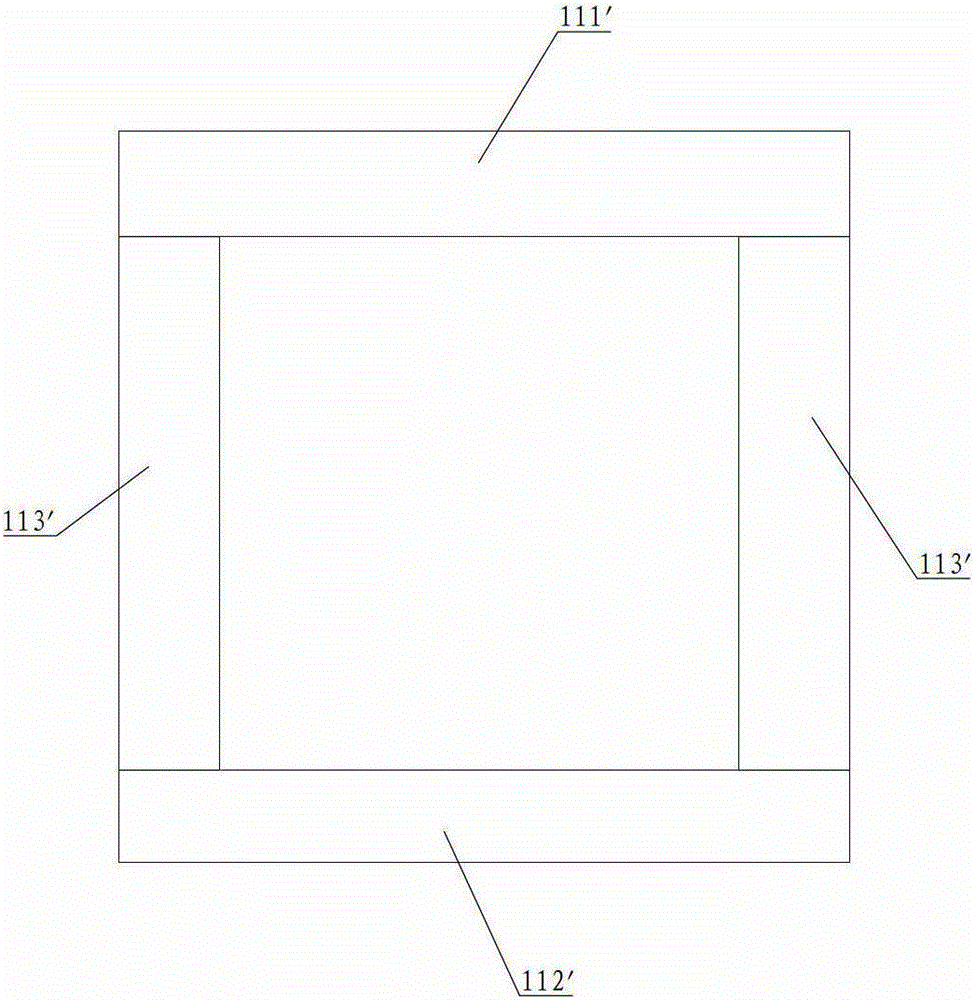

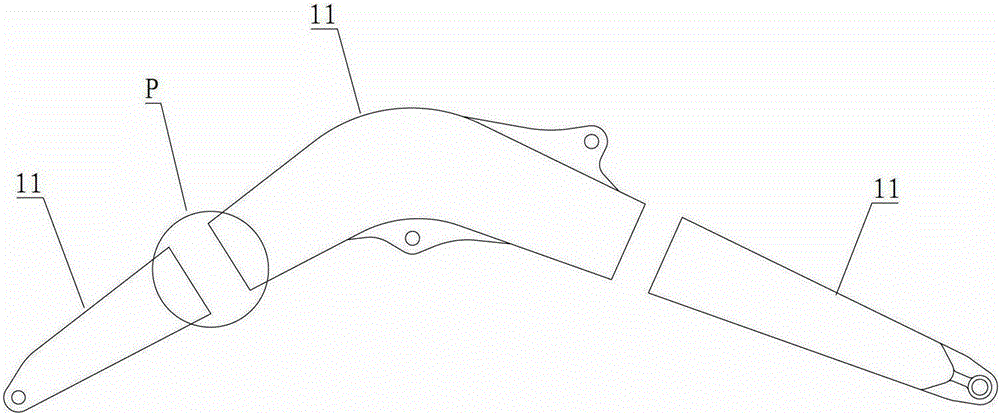

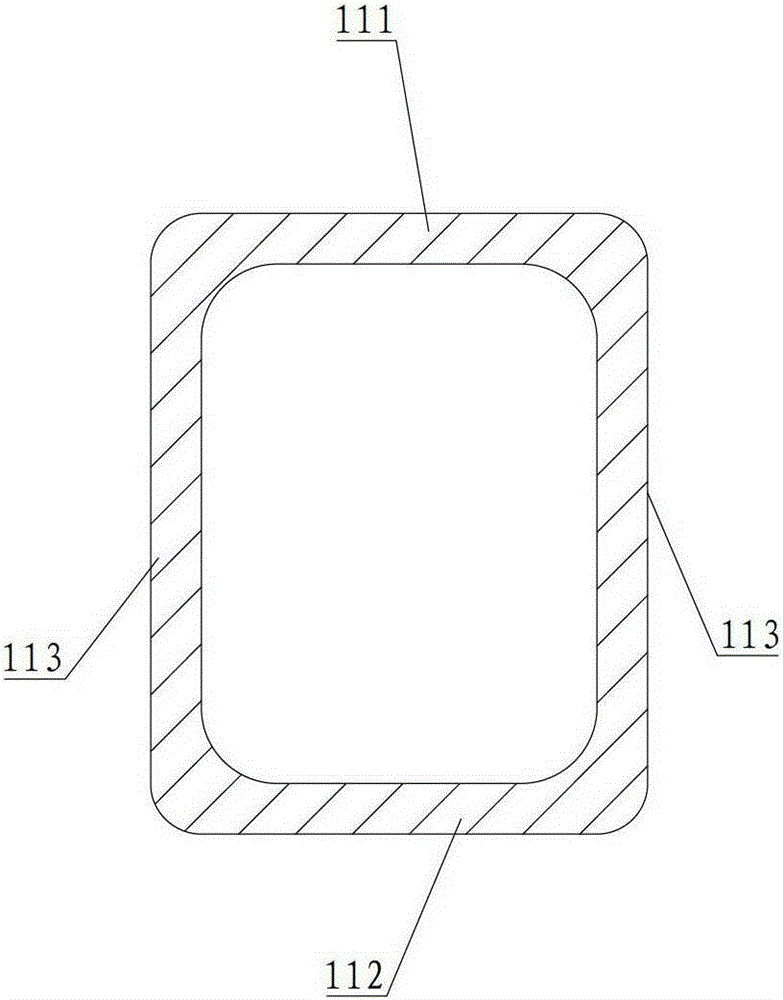

[0031] An embodiment of the present invention provides a box-shaped working device. The working device is a cast aluminum alloy, and the aluminum alloy is specifically an Al-Cu-Mn alloy, an Al-Zn alloy or an Al-Si alloy.

[0032] Compared with the existing working device, this embodiment adopts aluminum alloy to replace the original steel. Since the density of aluminum, the main component of aluminum alloy, is only one-third of that of copper or iron, the use of aluminum alloy can greatly reduce the weight of working devices. In addition, the surface of aluminum tends to naturally produce a layer of dense and firm Al 2 o 3 The protective film can well protect the substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com