A kind of high-entropy alloy containing eutectic structure and preparation method thereof

A high-entropy alloy and eutectic structure technology, which is applied to the above-mentioned high-entropy alloy preparation field, can solve the problems of low high-temperature strength and poor room temperature toughness of NiAl alloy, and achieves uniform structure and composition of the alloy, good casting fluidity, and fine structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

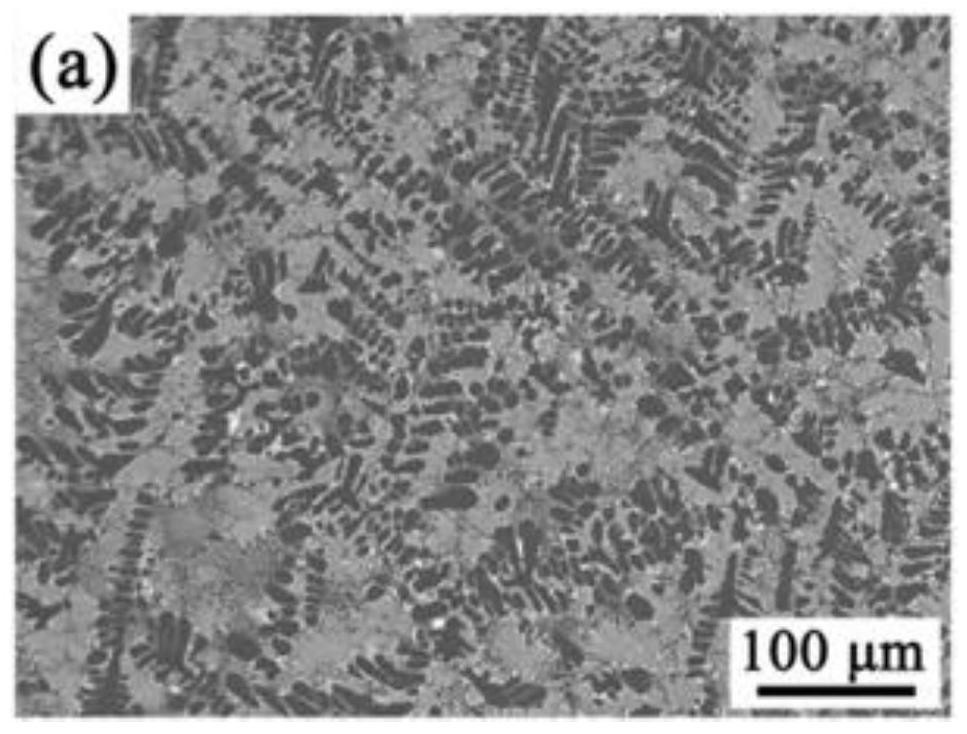

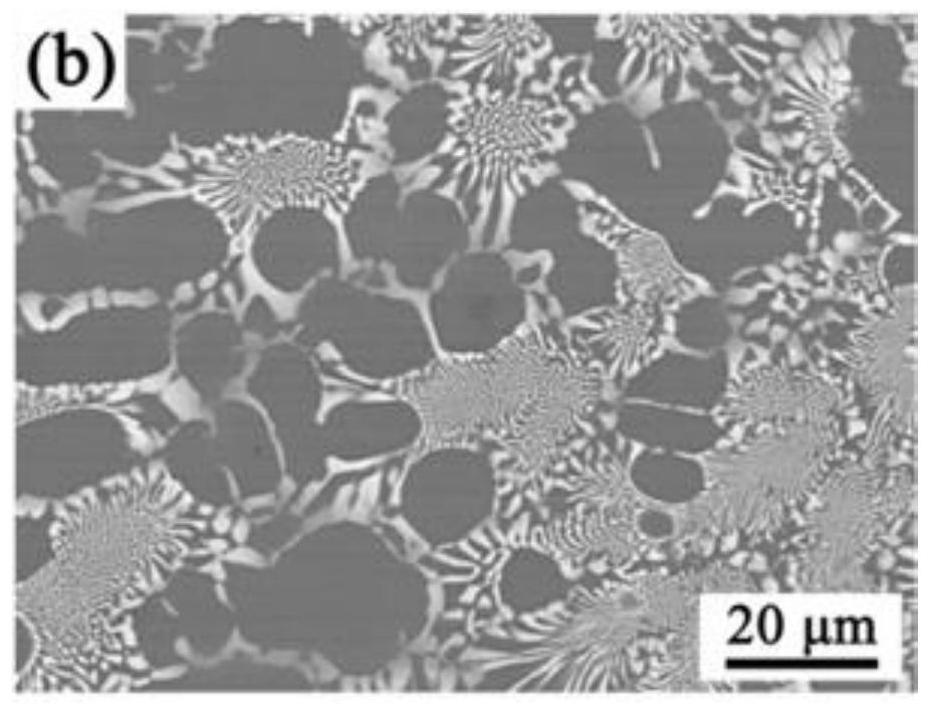

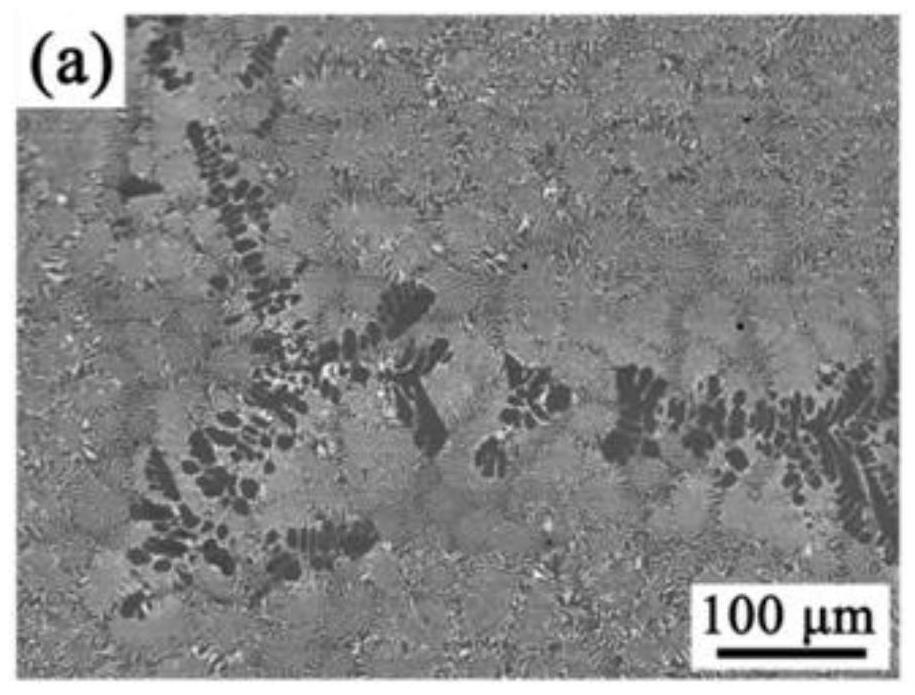

Embodiment 1

[0038] A method for preparing a high-entropy alloy containing eutectic structure, specifically implemented according to the following steps:

[0039] Step 1, according to the atomic ratio of (NiAl-Mo7.5Cr7.5V7.5, respectively weigh Ni block, Al block, Cr sheet, Mo wire and V block, the purity of Ni block is 99.96%, the purity of Al block is 99.99%, Cr The purity of sheet is 99.90%, the purity of moss is 99.95%, and the purity of V block is 99.90%;

[0040] Step 2. Pretreat the surface of Ni block, Al block, and Mo wire by pickling, specifically, use HF, HNO3 and water with a volume ratio of 1:1:2.0 to clean the Ni block for 10 minutes, and use volume Wash the Al block with HCl and water at a ratio of 1:1.5 for 10 minutes, and clean the Mo wire with HNO3 and water at a volume ratio of 1:1.5 for 5 min. After cleaning, place the Ni block, Al block, and Mo wire separately. Put them into different containers, add alcohol to soak for 5 minutes, remove impurities and acid attached t...

Embodiment 2

[0047] A method for preparing a high-entropy alloy containing eutectic structure, specifically implemented according to the following steps:

[0048] Step 1. According to the atomic ratio of NiAl-Mo8.33Cr8.33V8.33, respectively weigh Ni block, Al block, Cr sheet, Mo wire and V block, the purity of Ni block is 99.96%, the purity of Al block is 99.99%, and the Cr sheet The purity is 99.90%, the purity of moss is 99.95%, and the purity of V block is 99.90%;

[0049] Step 2. Pretreat the surface of Ni block, Al block, and Mo wire by pickling, specifically, use HF, HNO3 and water with a volume ratio of 1:1:2.5 to clean the Ni block for 15 minutes, and use volume The HCl and water with a ratio of 1:1.75 were used to clean the Al blocks for 15 minutes, and the Mo wires were cleaned with HNO3 and water with a volume ratio of 1:1.75 for 7.5 min. After cleaning, the Ni blocks, Al blocks, and Mo wires were cleaned separately Put them into different containers, add alcohol to soak for 7....

Embodiment 3

[0056] A method for preparing a high-entropy alloy containing eutectic structure, specifically implemented according to the following steps:

[0057] Step 1. According to the atomic ratio of NiAl-Mo8.7Cr8.7V8.7, respectively weigh Ni block, Al block, Cr sheet, Mo wire and V block, the purity of Ni block is 99.96%, the purity of Al block is 99.99%, and the Cr sheet The purity is 99.90%, the purity of moss is 99.95%, and the purity of V block is 99.90%;

[0058] Step 2. Pretreat the surface of Ni block, Al block, and Mo wire by pickling, specifically, use HF, HNO3 and water with a volume ratio of 1:1:2.5 to clean the Ni block for 15 minutes, and use volume The HCl and water with a ratio of 1:1.75 were used to clean the Al blocks for 15 minutes, and the Mo wires were cleaned with HNO3 and water with a volume ratio of 1:1.75 for 7.5 min. After cleaning, the Ni blocks, Al blocks, and Mo wires were cleaned separately Put them into different containers, add alcohol to soak for 7.5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com