Efficient bleaching process for silk clothes

A silk and clothing technology, applied in the field of bleaching, can solve the problems of incomplete bleaching, accelerate the shuttle of bleaching liquid molecules, and speed up the bleaching efficiency, so as to achieve the effect of speeding up the bleaching efficiency, making it difficult to contact each other, and improving the bleaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

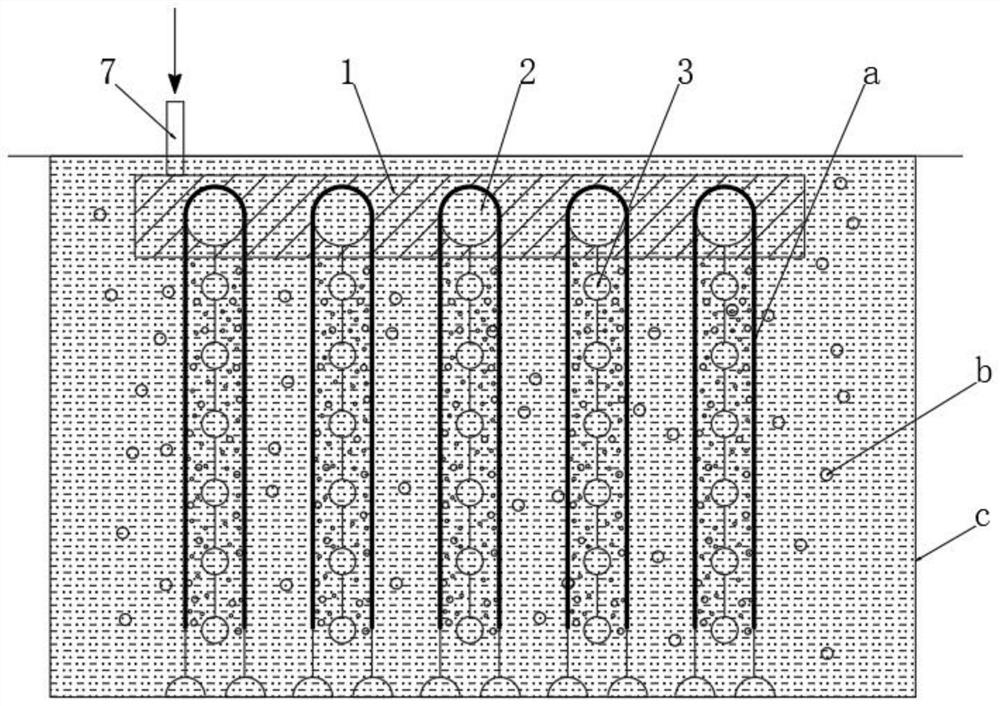

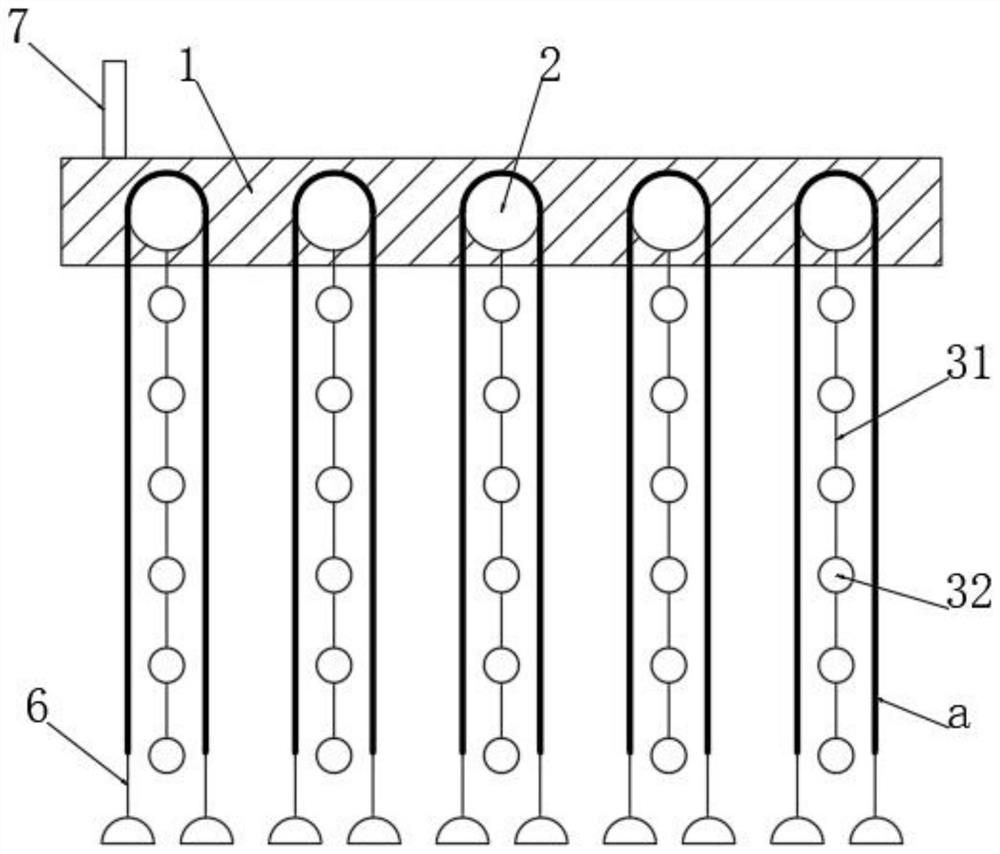

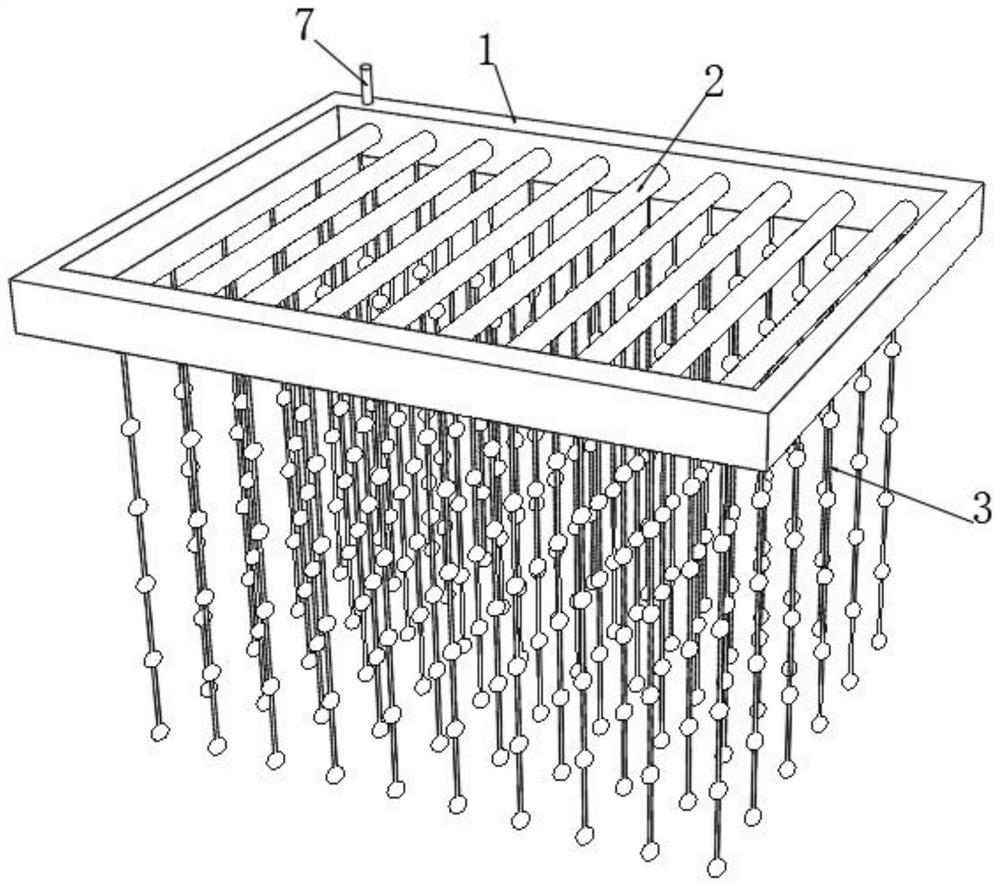

[0046] see figure 1 , in the figure, a represents silk, b represents air bubbles, and c represents a bleaching pool, a high-efficiency bleaching process for silk garments, comprising the following steps:

[0047] S1. Firstly hang the pieces of silk symmetrically on the spaced bleaching racks, and carry out the hanging ball 6 straightening on the bottom of each piece of silk in turn;

[0048] S2, then clip the spacer bleaching frame to the inner wall of the bleaching tank, and make the bleaching solution immerse the spacer bleaching frame;

[0049] S3. Inert gas is introduced into the spacer bleaching frame, so that the spacer bleaching frame produces a large number of air bubbles between each piece of silk, which has an impact on the silk, and at the same time drives the fluidity of the bleaching solution between the silks, and accelerates the bleaching solution molecules between the silks. Shuttle between;

[0050] S4. After bleaching, the silk is taken out, washed and air-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com