Antibacterial non-woven fabric as well as preparation method and application thereof

A non-woven fabric and non-woven fabric-based technology, applied in the field of materials, can solve the problems of poor dispersion, hindering the large-scale production and industrial application of quaternary ammonium salts, and achieve not easy to fall off, good application prospects, stable and uniform wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

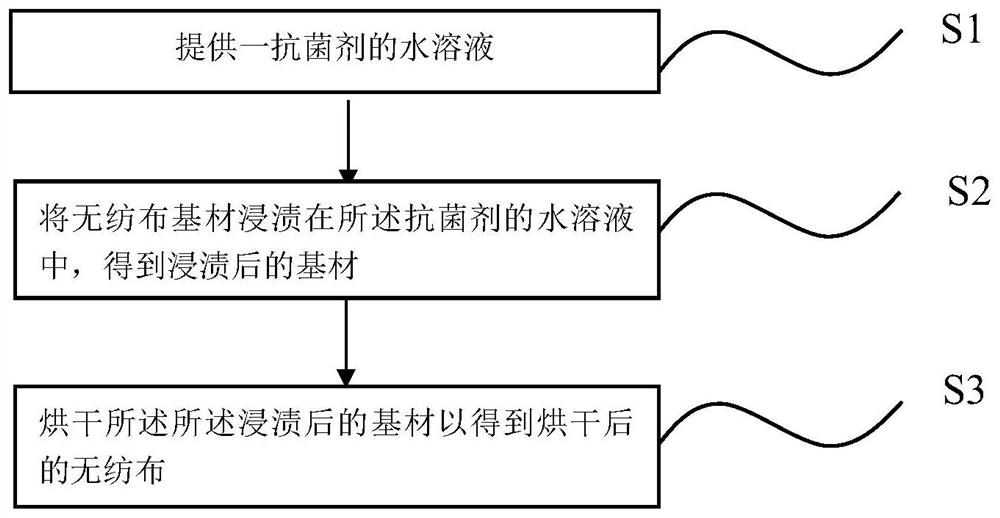

[0026] see Figure 1 to Figure 7 . The present invention at first provides a kind of preparation method of antibacterial non-woven fabric, and described method comprises the steps of S1~S3 at least:

[0027] — S1: providing an aqueous solution of an antibacterial agent;

[0028] —S2: immersing the non-woven fabric substrate in the aqueous solution of the antibacterial agent to obtain the impregnated substrate;

[0029] —S3: drying the impregnated substrate to obtain a dried non-woven fabric;

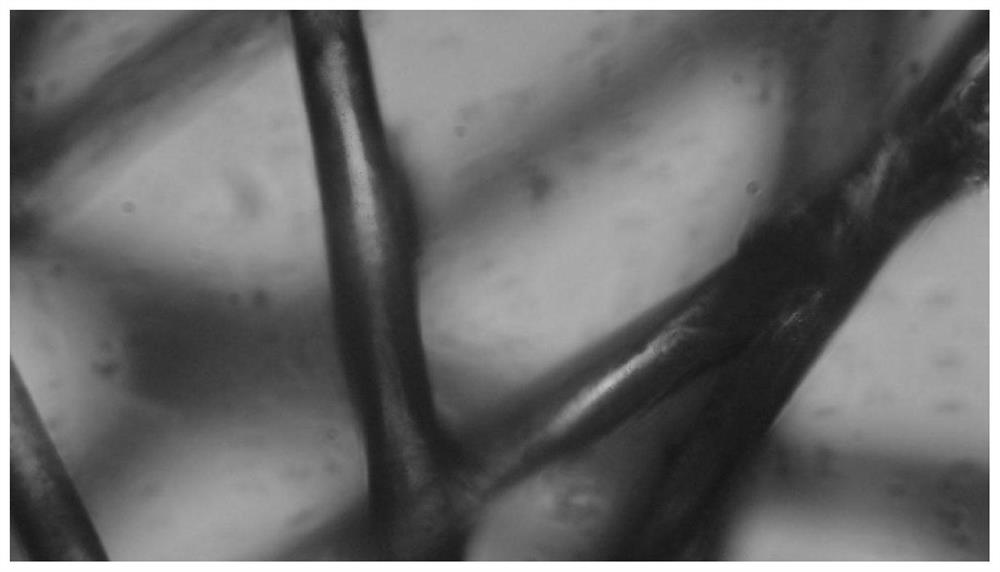

[0030] Wherein, the antibacterial agent includes the following components by weight percentage: the antibacterial agent includes the following components by weight percentage: 3% to 10% of quaternary ammonium salts, 1% to 10% of chitosan microspheres, 3% to 4% of surfactants, 80% to 90% of inorganic solvents, based on the weight of the aqueous solution of the antibacterial agent as 100%, the weight ratio of the antibacterial agent in the aqueous solution of the antibacterial agent is ...

Embodiment 1

[0047] The polyester non-woven fabric substrate was immersed in the antibacterial agent aqueous solution shown in Table 1, soaked thoroughly by ultrasonic impregnation, and dried to obtain sample 1.

[0048] The aqueous solution formula table of table 1 antibacterial agent

[0049]

Embodiment 2

[0051] Sample 2 was obtained by a preparation method similar to Example 1, and the specific antibacterial agent aqueous solution formula is shown in Table 2.

[0052] The aqueous solution formula table of table 2 antibacterial agent

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com