Microporous lithium foil production method and device

A production method and production device technology, applied in the field of microporous lithium foil production method and device, to achieve the effect of improving stability and stable and uniform coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: A microporous lithium foil with a porosity of about 20% was prepared by using a PET film as the substrate to be coated.

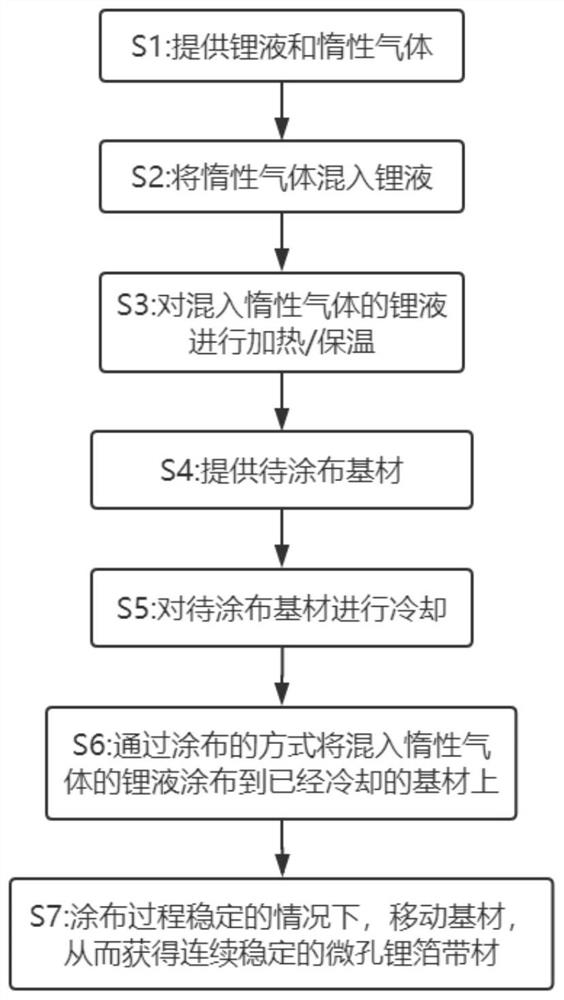

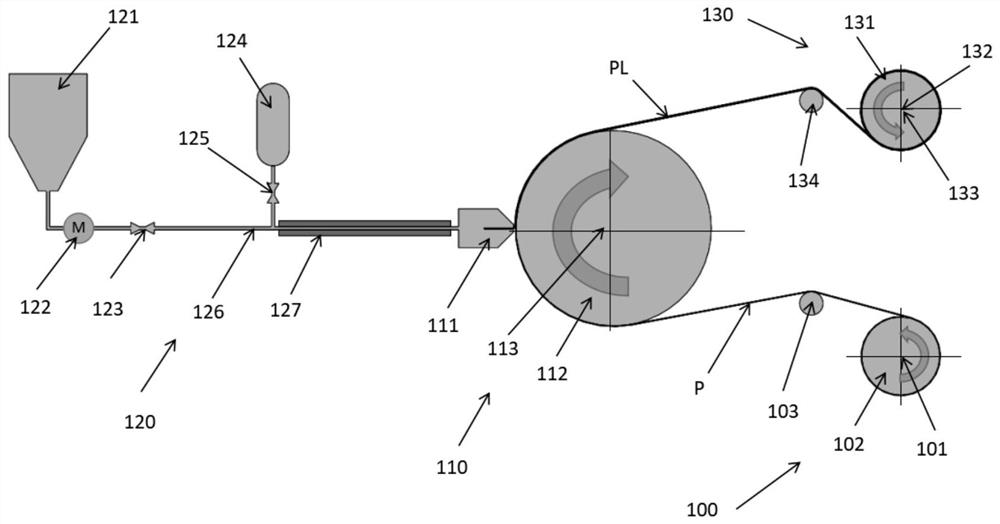

[0057] refer to figure 1 , execute step S1, provide lithium liquid and inert gas, lithium liquid in this embodiment is the metal lithium liquid prepared after melting the battery-grade metal lithium with a purity of 99.9% or more, and the inert gas is high-purity argon with a purity of 99.999% or more; execute Step S2, mix argon gas into the lithium liquid, and control the volume ratio of argon gas and lithium liquid to 1:4; execute step S3, heat and keep warm the lithium liquid mixed with argon gas, and the heating temperature is 300°C; execute step S4 , provide the base material to be coated, the base material to be coated provided in the present embodiment is polyethylene terephthalate (PET) film, width 300mm, thickness is 50 μ m; Execute step S5, PET film is cooled , so that the cooling temperature is -20°C; Execute step S6, apply the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com