Device for reinforcing UHPC-NC interface bonding through split bolts and manufacturing method

A technology of UHPC-NC and pull bolts, which is applied in the direction of erection/assembly of bridges, buildings, bridge construction, etc., can solve problems such as insufficient bonding, and achieve good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a deeper understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

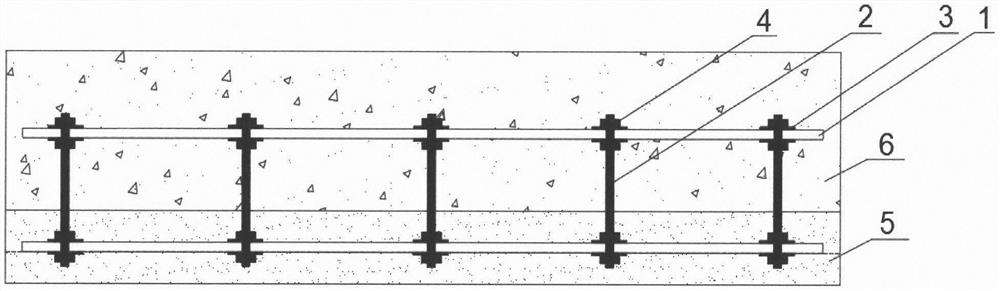

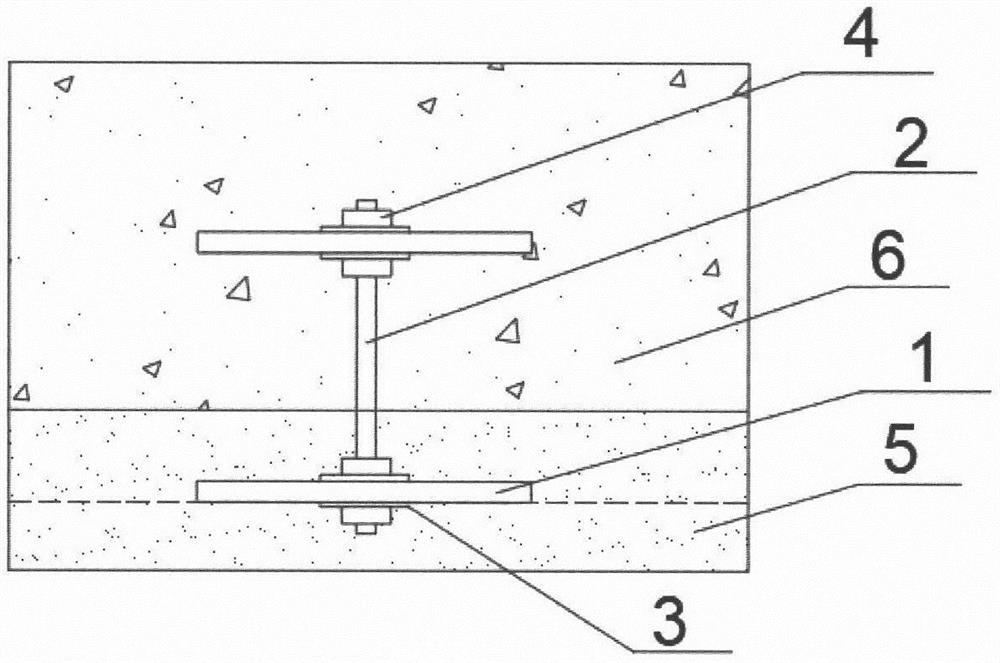

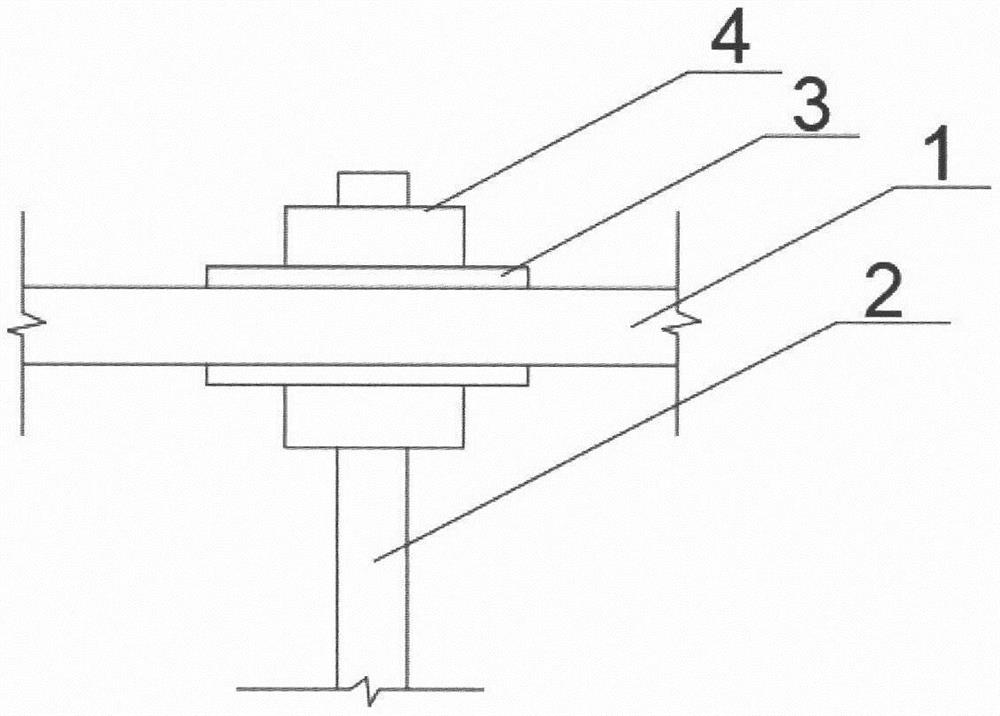

[0024] Please refer to the attached figure 1 ~ attached image 3 , in the example of the present invention, a device for strengthening the bonding of UHPC-NC interface by using a pull bolt, including a high-quality steel plate 1 and a pull bolt 2, the high-quality steel plate 1 is selected as the fixture at both ends of the pull bolt 2, and the high-quality steel plate 1 Open a hole on the central axis in the length direction for inserting the tension bolt 2, insert the cast steel gasket 3 on the tension bolt 2 on both sides of the opening of the high-quality steel plate 1, and use the nut 4 to connect the high-quality steel plate 1 and the tension bolt 2 Fix and tighten, two high-quality steel plates are poured horizontally in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com