Anti-falling connecting piece, machining method and using method

A technology of connecting pieces and connecting sleeves, which is applied in earth-moving drilling, mining equipment, installation of bolts, etc., can solve problems such as affecting engineering safety and loosening of fasteners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

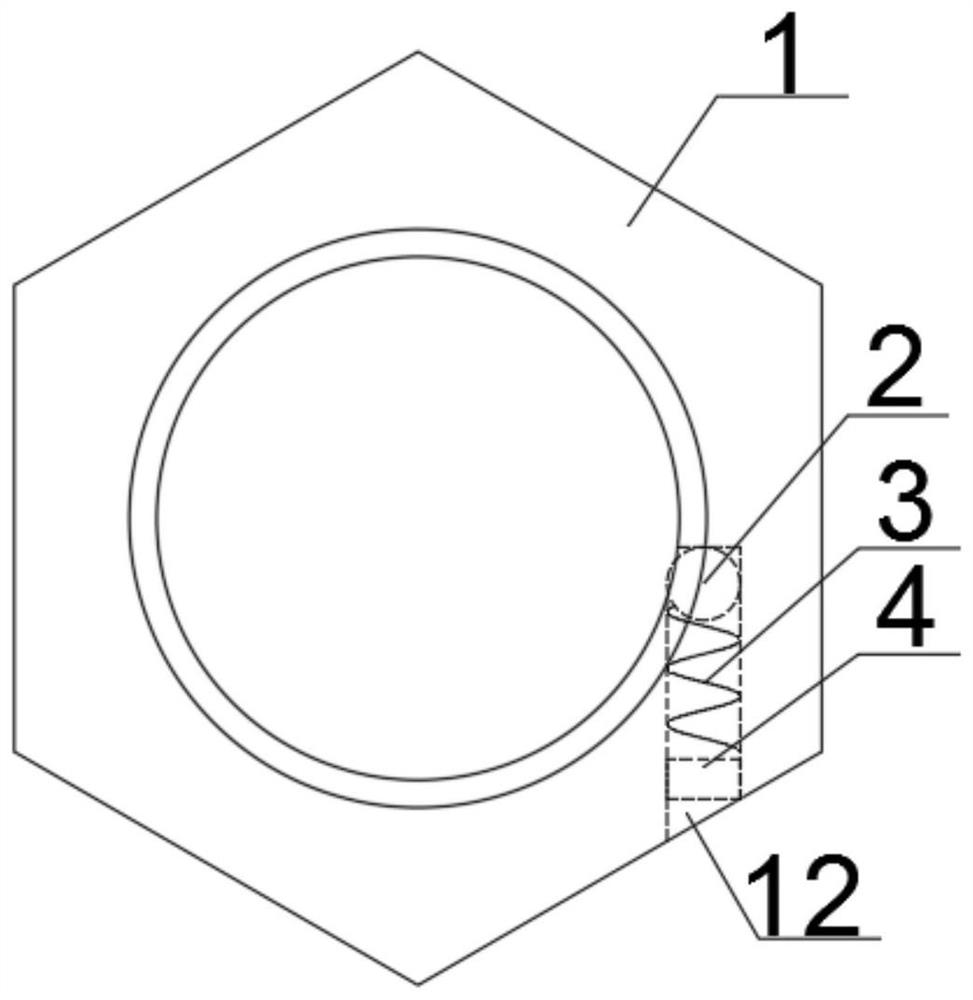

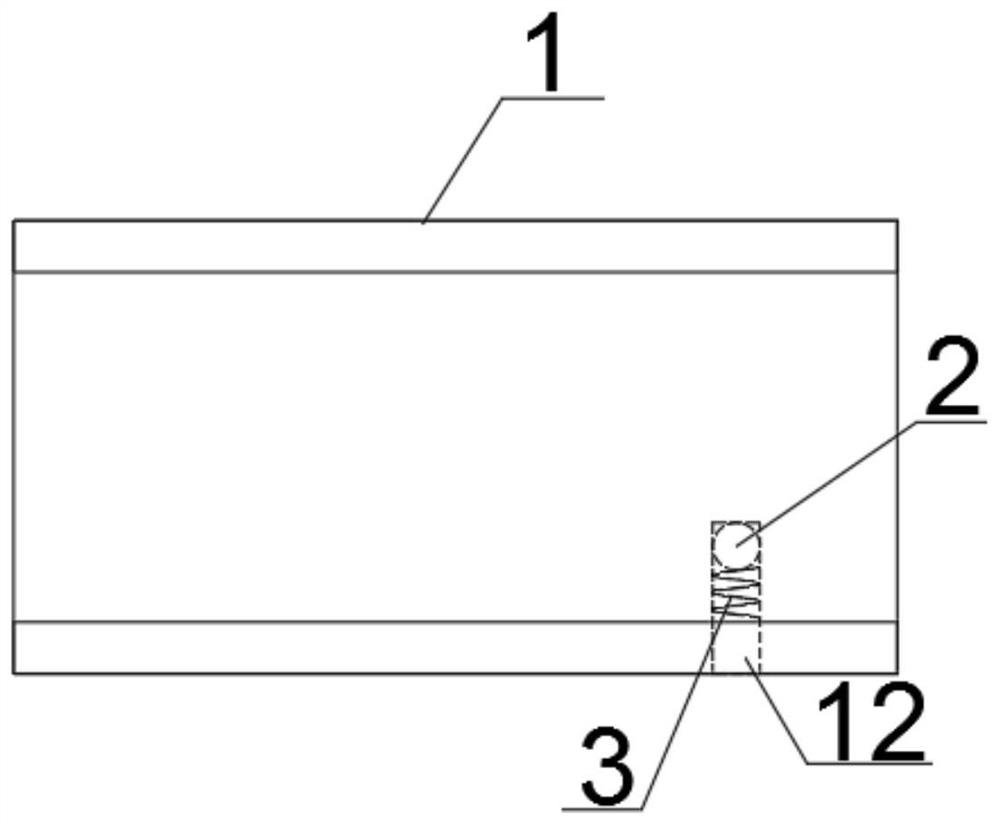

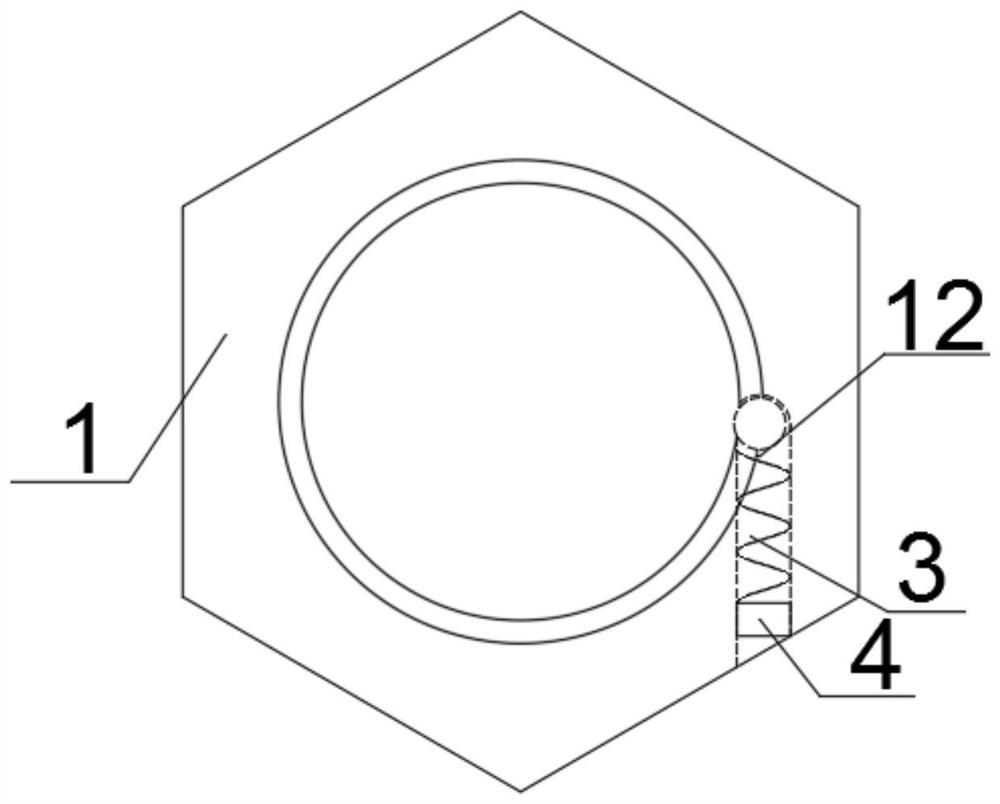

[0034] refer to Figure 1-3 , The present embodiment discloses an anti-off connector, which includes a connecting sleeve 1 and an anti-off part; the anti-off part includes a limiting hole 12, a steel ball 2, and a spring 3.

[0035] The inner wall of the connecting sleeve 1 is provided with threaded threads, and the outer wall is provided with a limit hole 12 along the tangential direction of the inner cavity. 3. The top of the limit hole 12 is fixedly connected with the cover 4, and the steel ball 2 is limited at the bottom of the limit hole 12. Under the restriction of the steel ball 2 and the cover 4, the spring 3 is under pressure, and the limit hole 12 is preferably circular hole.

[0036] In this embodiment, the steel ball 2 is located between the threaded wires on the inner wall of the connecting sleeve 1 .

[0037] In this embodiment, the bottom of the limiting hole 12 can be set as a flat bottom or an arc bottom matching the steel ball 2 .

[0038] In this embodime...

Embodiment 2

[0044] refer to Figure 4-5 The difference between the second embodiment and the first embodiment is that the connecting sleeve 1 also includes a stud 5, and the stud 5 is fixedly connected to one end of the connecting sleeve 1 by means of coaxial fixing or angle fixing, and the anti-loosening part is arranged on the connecting Set the other end of 1 to suit different connection needs.

Embodiment 3

[0046] refer to Figure 6 The difference between the third embodiment and the first embodiment is that the two ends of the connection sleeve 1 are respectively provided with anti-slip prevention parts in opposite directions to meet different connection requirements.

[0047]In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Obviously, the described embodiments are part of the present invention Examples, not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com