Air suction and noise reduction cover device, compressor and method

A sound-absorbing cover and sound-absorbing technology, which is applied in the field of compressors, can solve problems such as leakage, small oil retaining ribs, and increased material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

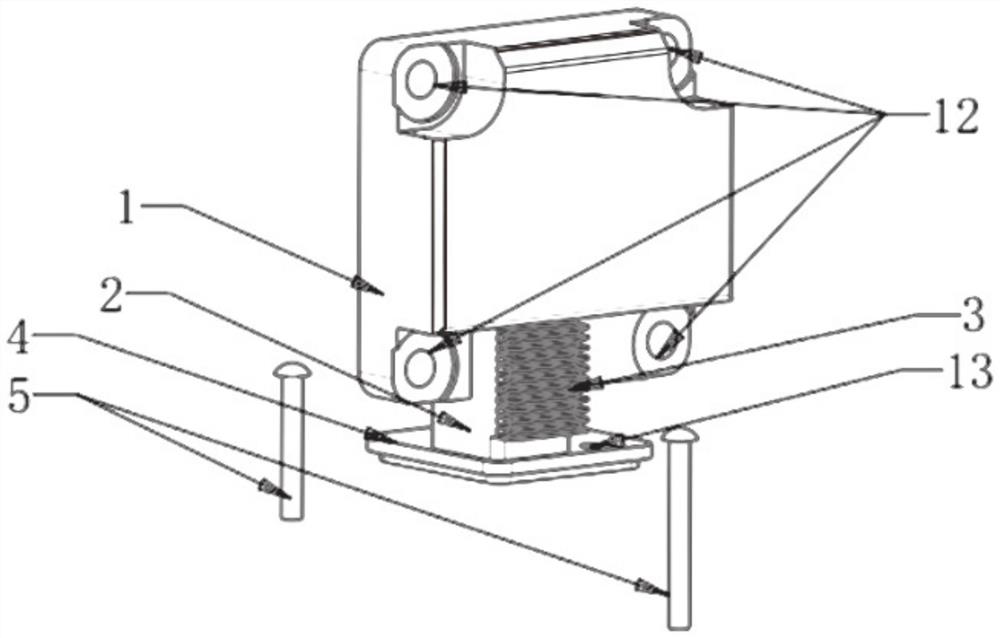

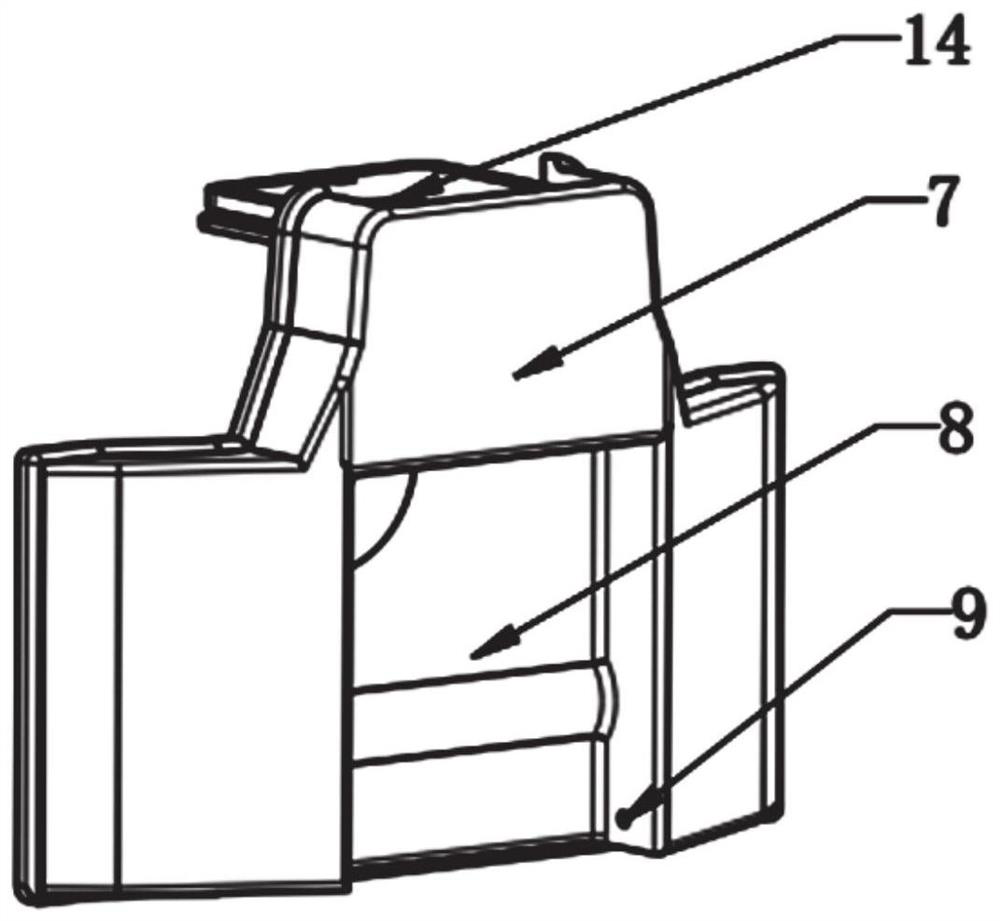

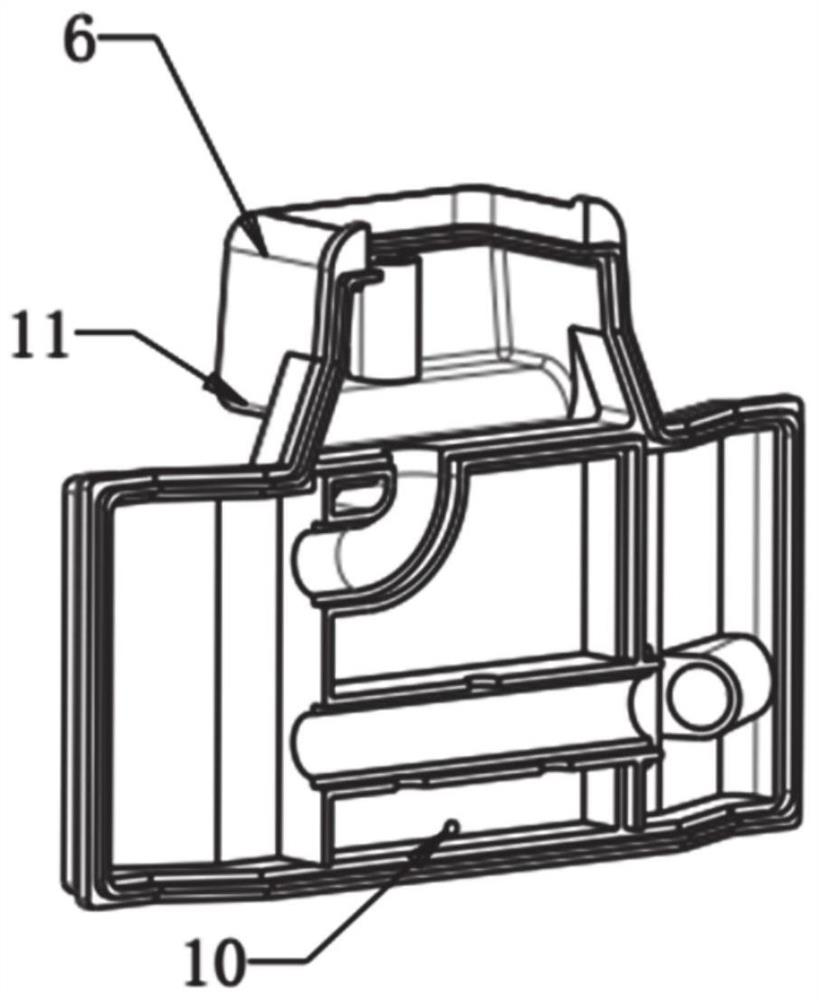

[0034] In a typical implementation of the present invention, this embodiment discloses a suction muffler cover device, including a first casing 7, a second casing 6, a cylinder head 1 and a heat dissipation mechanism, the first casing 7 and the second casing The two housings 6 cooperate to form a sound-absorbing container 15, and the inside of the sound-absorbing container 15 forms a sound-absorbing cavity, and one end of the cylinder head 1 is connected to the sound-absorbing container 15, and the cylinder head 1 is equipped with a cooling mechanism.

[0035] Further, both the first shell 7 and the second shell 6 are made of plastic, including but not limited to PBT resin, PPS material and the like.

[0036] It can be understood that after using plastic materials, the manufacturing process of the first shell 7 and the second shell 6 can be completed by injection molding, etc. The current injection molding process can manufacture shells with relatively complex shapes to form mu...

Embodiment 2

[0061] In a typical implementation of the present invention, this embodiment discloses a compressor, including the suction noise reduction cover device as described in Embodiment 1, and the cylinder head 1 in the suction noise reduction cover device is connected to the main body of the compressor.

Embodiment 3

[0063] In a typical implementation of the present invention, this embodiment discloses a compressor noise reduction method, using the suction noise reduction cover device as described in Embodiment 1, including the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com