Novel dry-wet cooling tower and evaporative condenser

An evaporative condenser and cooling tower technology, which is applied in the field of cooling towers, can solve the problems of reducing the static air pressure of the system, fouling the surface of heat exchange elements, and difficulty in handling, so as to increase relative volatility, reduce floor space, The effect of accelerating evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

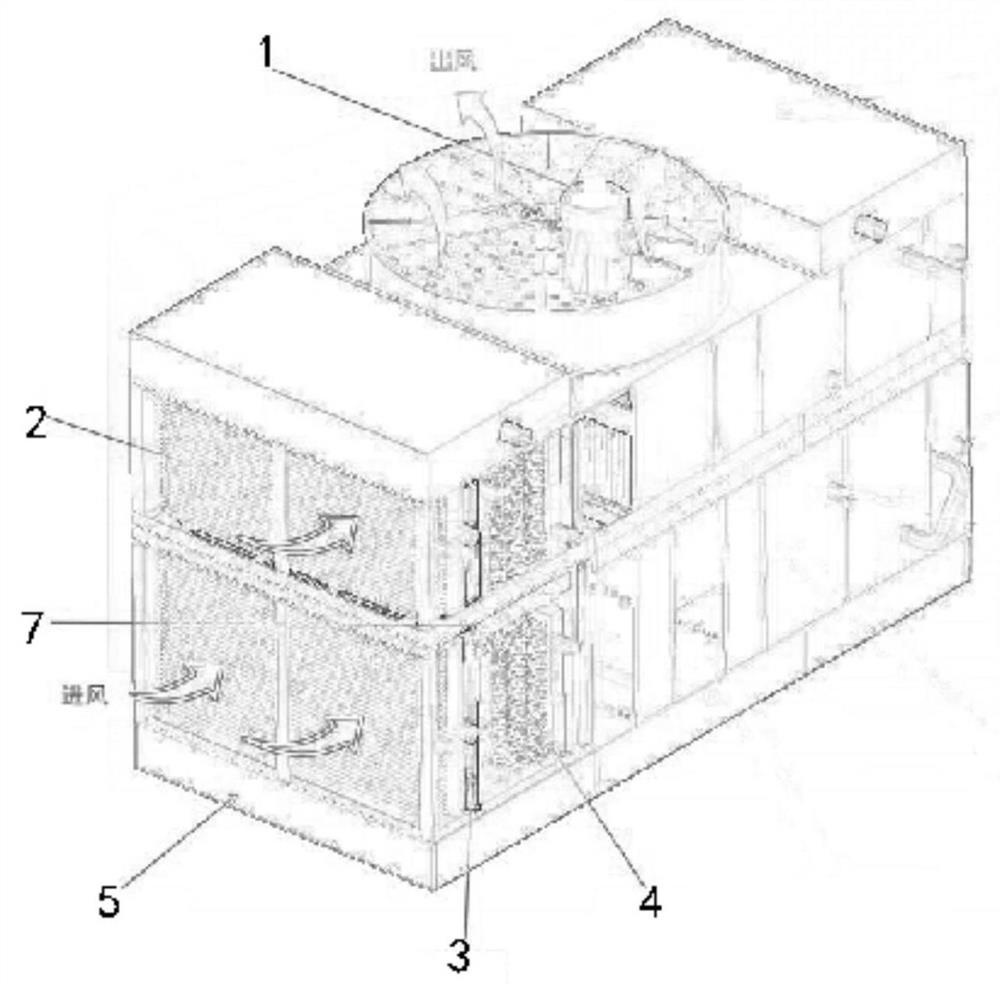

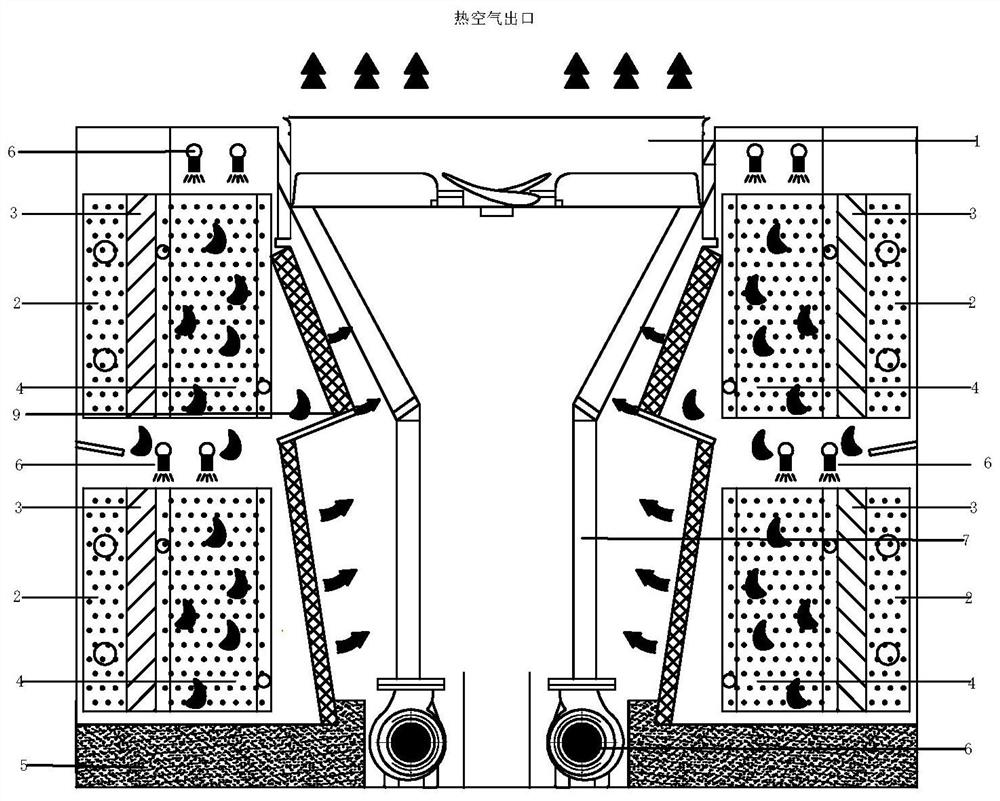

[0024] Depend on Figure 1 to Figure 2 It can be seen that a new type of dry and wet cooling tower and evaporative condenser provided by the present invention includes: an equipment frame, the basic heat exchange unit of the upper and lower layers of dry and wet combined exchange is arranged inside the equipment frame, and the bottom of the equipment frame is a water collection tank , the top of the equipment frame is provided with a fan; each layer of basic heat exchange units is provided with two opposing groups, the basic heat exchange units include: fin heat exchangers, spray heat exchangers, and the fin heat exchangers are close to the equipment The side wall of the frame is arranged at the air inlet, and the spray heat exchanger is arranged on the side of the fin heat exchanger away from the side wall of the equipment frame; each layer of basic heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com