Reduced scale type full-section rock tunneling test device based on multifunctional cutterhead

A technology of tunnel excavation and test device, applied in the field of mechanical design, can solve the problems of difference in rotary cutting action, reliability, and difficulty in realizing economic cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to explain the technical content, operational flow, the objects and effects of the present invention, the following examples are given.

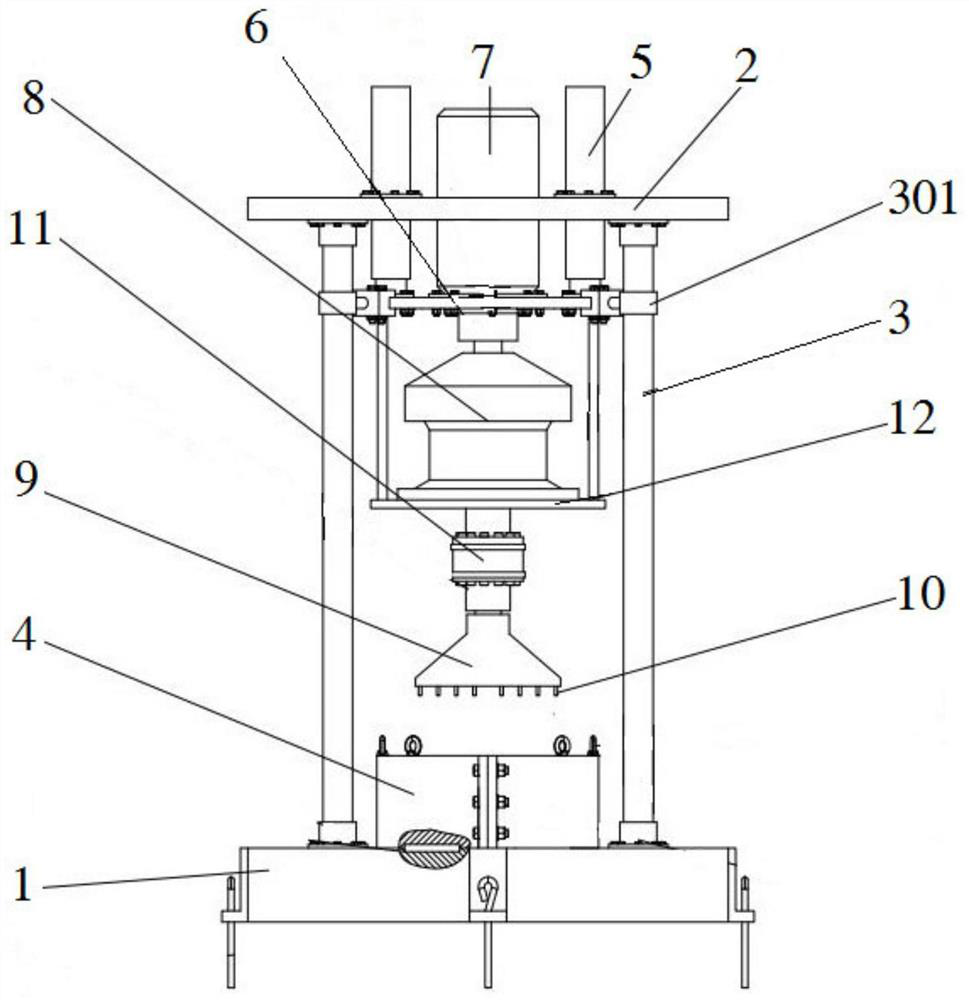

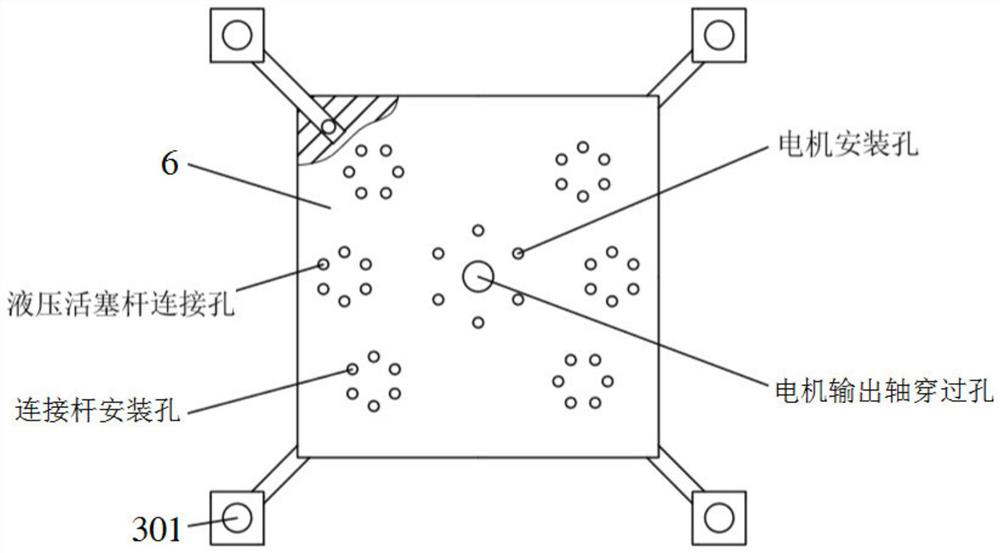

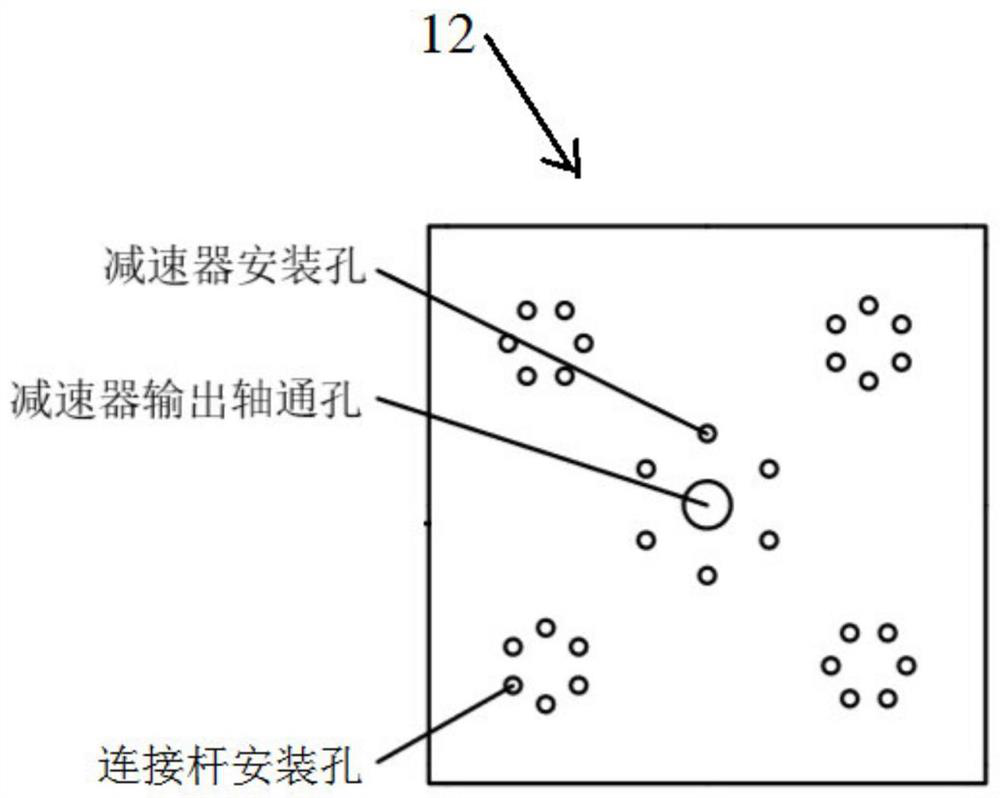

[0034] reference Figure 1 - Figure 3 According to a multi-function type full-section rock tunneling tunnel, a multi-functional cutting type full-section rock tunnel, including: a top seat 2 and a base 1 provided up and down, and the base 1 and the top seat 2 pass the column 3 Support connection; the base 1 is fixed to the rock box 4, the rock box 4 is provided to be taken into the test piece; the top seat 2 is fixed to the push member 5, and the movable member of the propulsion member 5 is connected to the movable seat. 6. The movable seat 6 moves up and down with the movable member of the propulsion member 5; a drive member is provided, and a cutter disk 9 is connected to the output shaft of the drive member, and the cutter disk is set. The disc hob 10.

[0035] reference figure 1 with figure 2 According to an embodiment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com