Electromagnetic swing type vibrating screen

A vibrating screen and swinging technology, which is applied in the field of electromagnetic swinging vibrating screens, can solve the problems of difficulty, single online amplitude modulation capability, and easy damage and cracking of bearings, so as to reduce operating costs, improve energy conversion efficiency, and reduce the cost of lifting the car. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

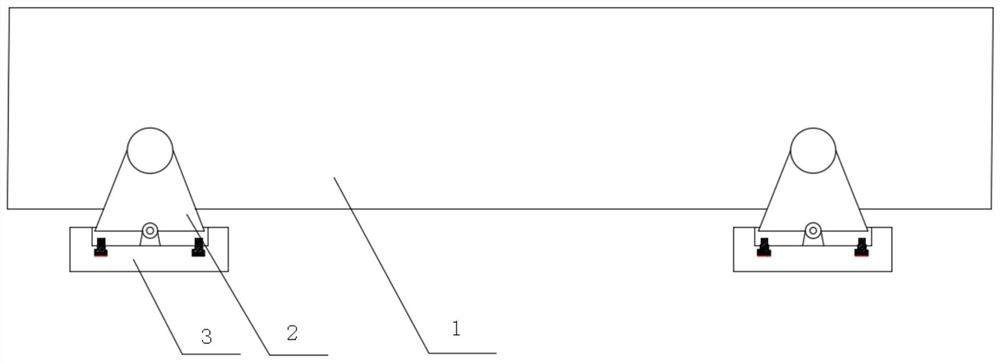

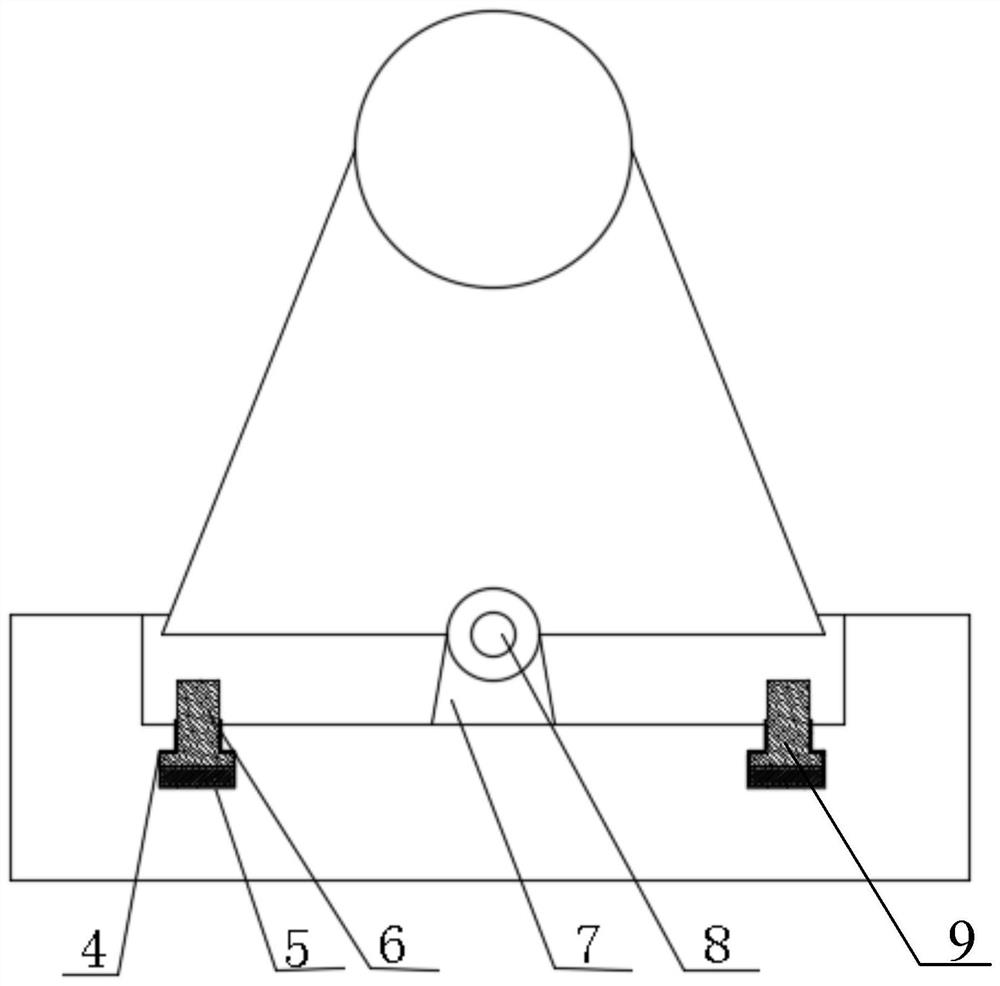

[0021] Example: as attached figure 1 , 2 As shown, this electromagnetic swing vibrating screen includes a vibrating screen box body 1, a fixed bracket 2, a fixed electromagnetic seat body 3, an insulating sleeve body 4, an elastic block 5, a front electromagnetic block 6, a movable support 7, and a bearing rotating body 8 and the rear electromagnetic block 9, the vibrating screen body is fixed in the vibrating screen box 1 through bolts or rivets, and each of the four corners of the vibrating screen box 1 is provided with a fixed electromagnetic base body 3, each fixed The electromagnetic seat body 3 is fixed with a movable support 7, and the movable support 7 is rotationally connected with the bottom of the fixed support 2 through the bearing rotating body 8, and the fixed support 2 is fixed on the vibrating screen box body 1; The front electromagnetic block 6 and the rear electromagnetic block 9 are fixed on the side, and the front electromagnetic block 6 and the rear elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com