Hot welding mechanism for pull-ups

A technology of pull-up pants and heat welding, which is applied in the direction of electrostatic cleaning, smoke removal, and particle filtration, can solve the problems of high defect rate of pull-up pants and difficult reduction of heating temperature, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

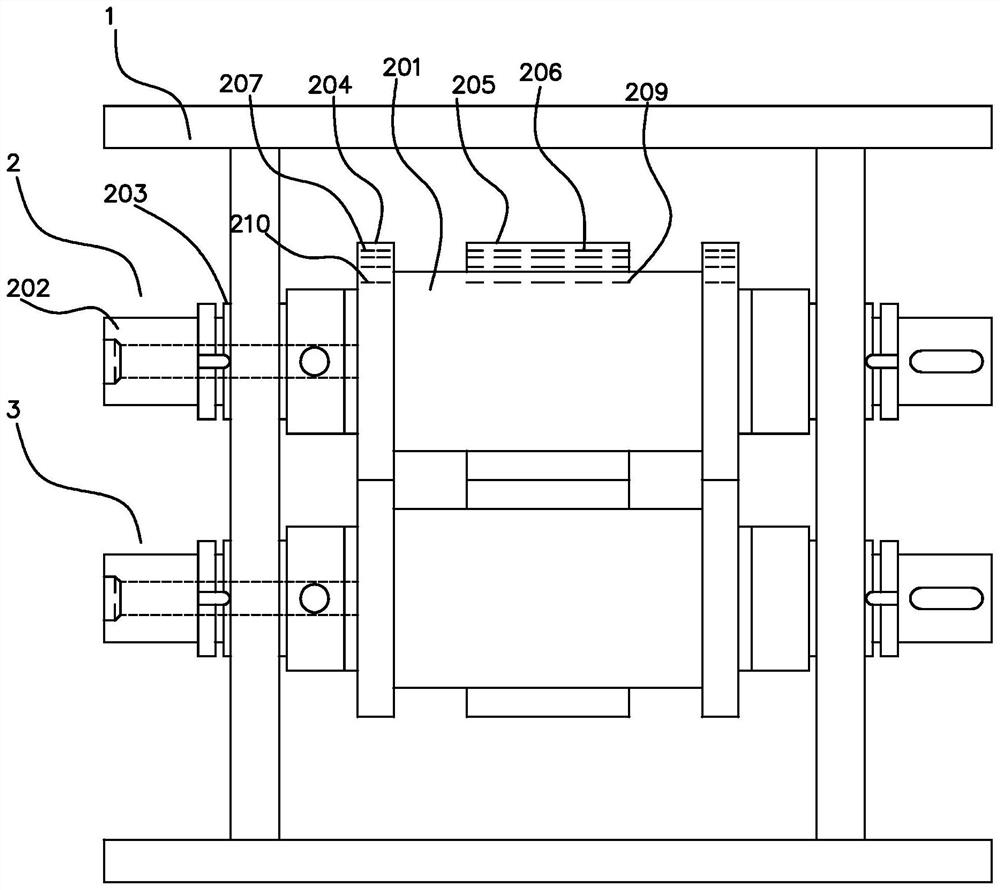

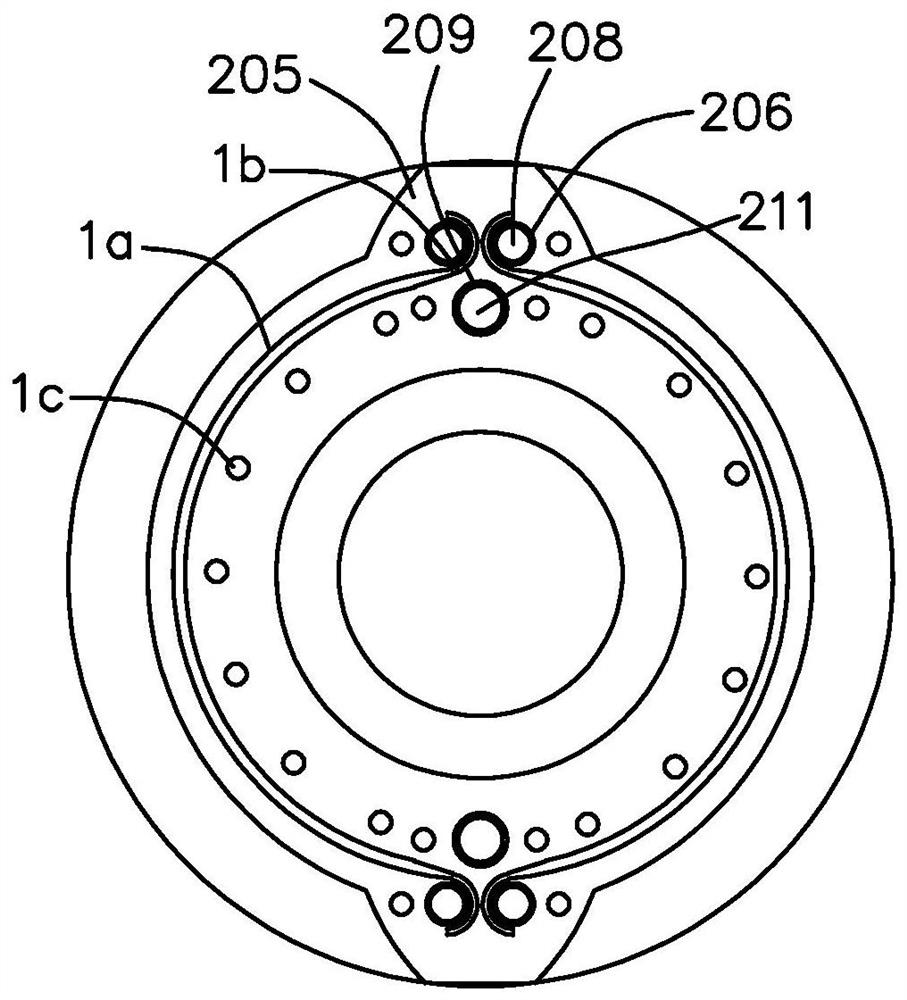

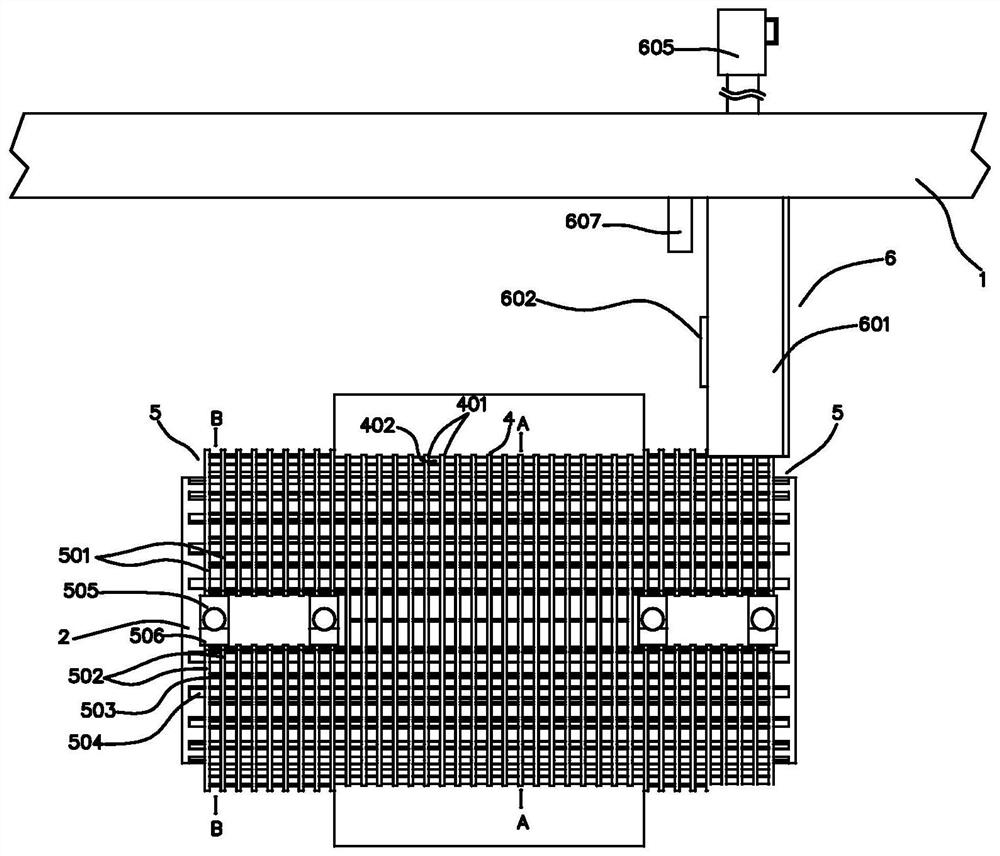

[0039] refer to Figure 1 to Figure 2 , the first embodiment provides a heat welding mechanism for pull-up pants, including a frame 1, a first welding roller 2 arranged at the top of the frame 1, and a second welding roller 3 arranged at the bottom of the frame 1, the first The welding roller 2 includes a roller body 201, connecting shafts 202 arranged on both lateral sides of the roller body 201, round rollers 203 arranged on both lateral sides of the roller body 201, and arranged on the roller body 201 and arranged at intervals on both lateral sides of the round roller 203. The pressing ring 204, the plurality of welding blocks 205 equiangularly arranged on the outer surface of the round roller 203, the first pipe holes 206 arranged transversely in the welding block 205, and the plurality of second pipe holes equiangularly arranged in the pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com