Multi-parameter on-line monitoring device for fermentation process

A fermentation process and monitoring device technology, applied in the field of food analysis and quality research, can solve the problems of changing the yield and quality of fermented products, complex processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

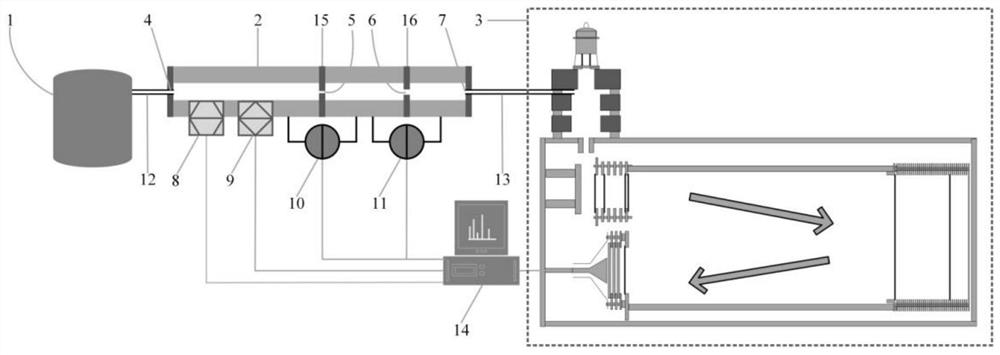

[0048]For the fermentation process multi-parameter online monitoring device and method according to the present invention, the specific parameters are set as follows: the inner diameter of the fermentation state monitoring system 2 is 12mm, the inner diameter of the fermentation sampling pipeline 12 is set to 8mm, and the inner diameter of the fermentation pipeline 13 is set to 6mm, The inner diameter of the fermentation gas inlet 4 is set to 6mm, and the inner diameter of the fermented gas outlet 7 is set to 4mm; the inner diameter of the center through hole A5 of the partial pressure baffle A15 is 3mm; the inner diameter of the central through hole B6 of the partial pressure baffle B16 is 2mm; the inner diameter of the partial pressure baffle A15 and The distance between the fermentation gas inlet 4 is set to 40mm; the distance between the partial pressure baffle B16 and the partial pressure baffle A15 is set to 80mm; the distance between the fermentation gas outlet 7 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com