Roof exhaust channel and construction method thereof

A construction method and steam exhaust channel technology, which is applied in the field of building roof structure, can solve the problems of roof waterproof swelling, loss of steam exhaust function, etc., and achieve the effect of avoiding swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

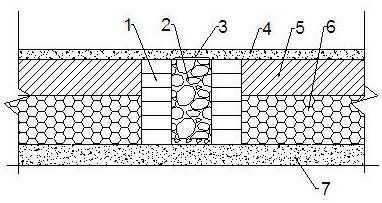

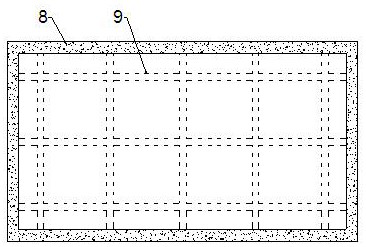

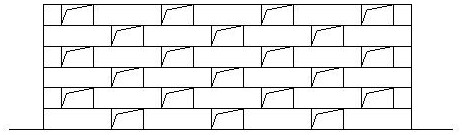

[0033] see figure 1 and image 3 , a roof steam exhaust duct, comprising exhaust steam ducts arranged horizontally and vertically, a PVC standpipe 11 is provided at the intersection of the horizontal and vertical steam exhaust ducts, the walls of the PVC standpipe 11 are densely covered with through holes, and the through holes are distributed in a plum blossom shape; Both sides of the steam exhaust channel are supported walls 1 made of gray bricks, and the middle is filled with broken aerated blocks 2; Above the bag pavement 3 are the leveling layer 4 and the waterproof layer 10 of the roof structure in sequence.

[0034] Preferably, the part height of the through hole provided on the PVC standpipe 11 reaches th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com