Assembled mortise and tenon bracket type beam-column joint connecting device

A technology of beam-column joints and connecting devices, which is applied in the direction of building types, protected buildings/shelters, building components, etc., can solve the problems of insufficient joint integrity, heavy cast-in-place workload, and insufficient earthquake resistance, so as to avoid Wet work workload and construction period consumption, improve earthquake resistance, ensure the effect of aesthetics and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail through the following embodiments and in conjunction with the accompanying drawings.

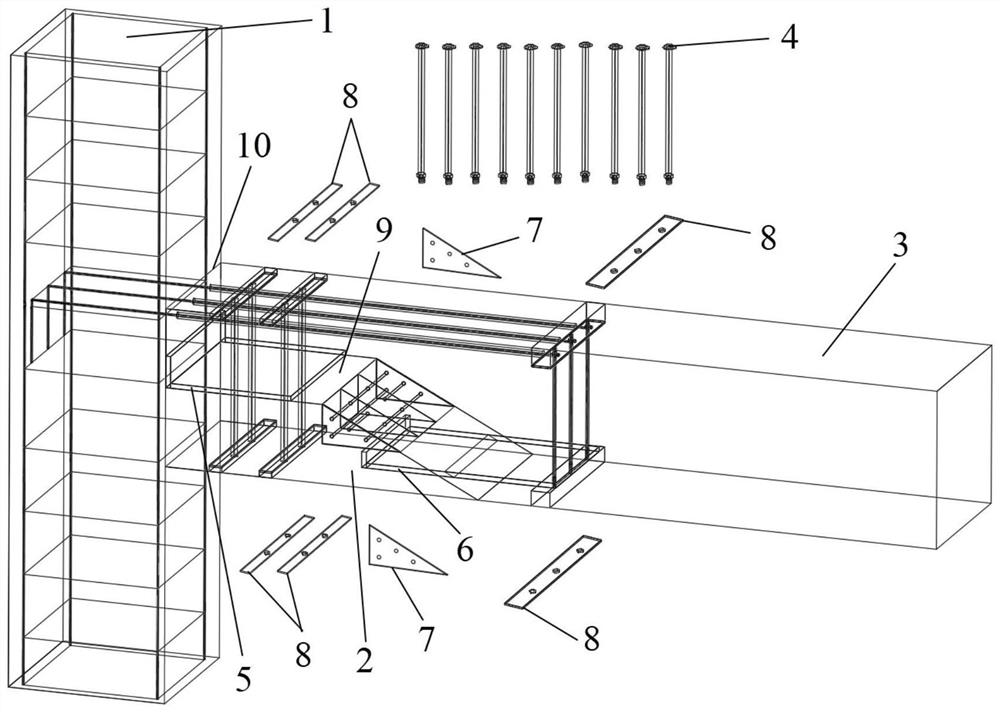

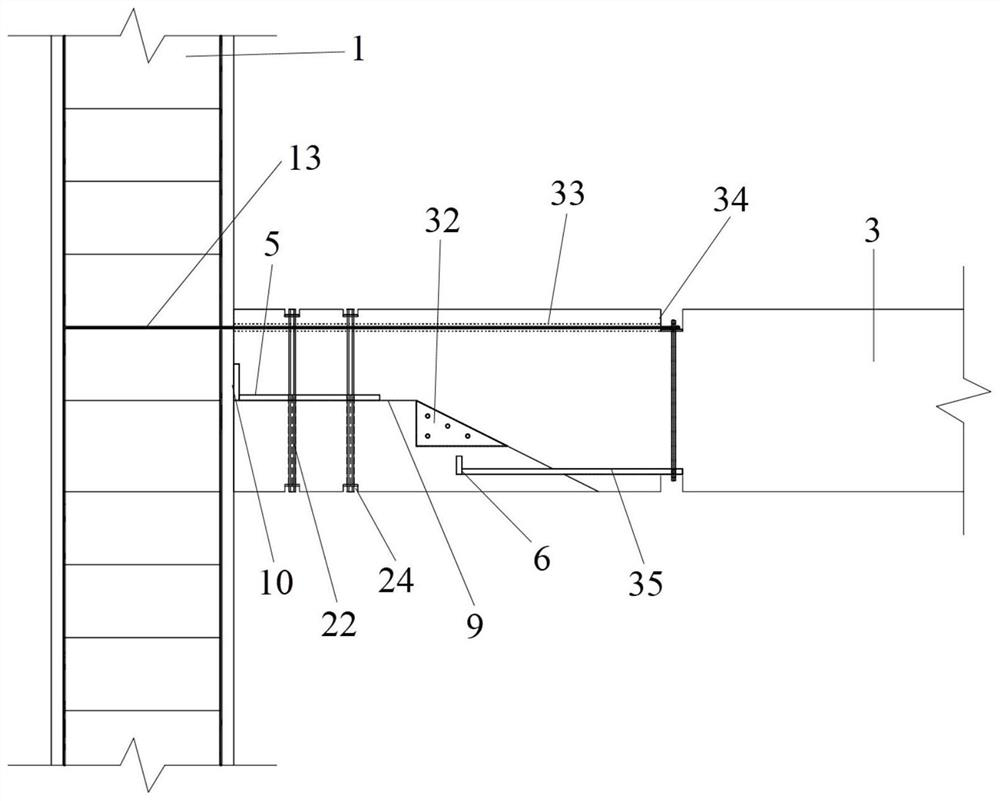

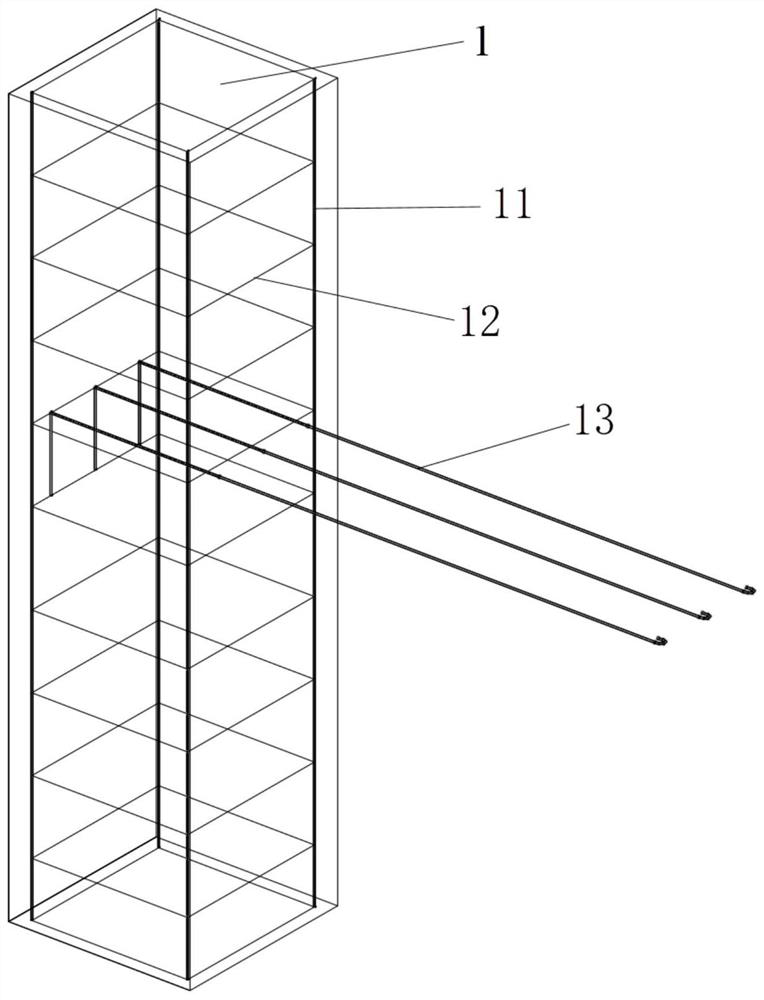

[0034] combine Figure 1-Figure 8 , an assembled mortise and tenon corbel-type beam-column joint connection device of the present invention, comprising a prefabricated column 1 for beam-column joint connection, a concealed corbel 2, a prefabricated beam 3, a high-strength bolt 4, and an L-shaped steel plate 5 at the beam end , Corbel pre-embedded L-shaped steel plate 6, triangular bearing plate 7, rectangular bearing plate 8, nitrile rubber gasket 9 and mortar filling layer 10. The prefabricated column 1 is provided with vertical ribs 11, hoops 12 and L-shaped steel bars 13 with curved hooks protruding from them. The outer end of the reinforcing bar 13 with a crotch is provided with a crotch. The prefabricated column 1 and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com