Coring drilling tool with compressed air as conveying medium and scouring medium

A technology for conveying media and compressed air, which is applied in earthwork drilling, undisturbed core extraction devices, construction, etc. It can solve problems such as drill sticking, short drilling distance, and rapid wear of seals, so as to improve working life and efficiency, reduce Small traveling resistance, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

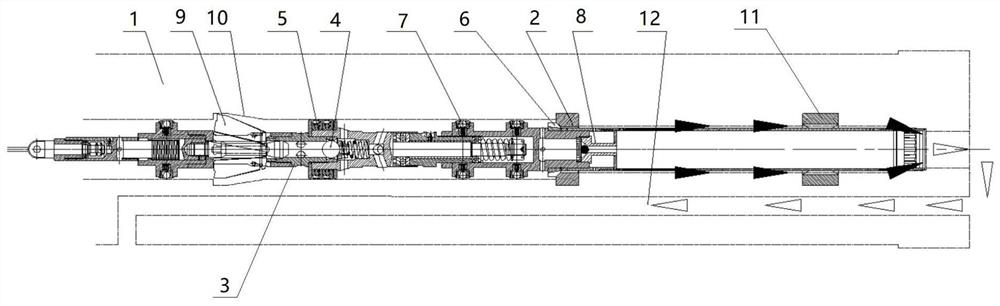

[0029] see figure 1 , a core drilling tool using compressed air as the conveying medium and flushing medium, including a coring device and an auxiliary device; the auxiliary device includes a drill rod 1 and a positioning ring 2 arranged in the drill rod 1; the coring device The device includes a rod body 3, a passing mechanism 4, a sealing ring 5 and a suspension ring 6; the rod body 3 is sleeved in the drill pipe 1; there is a gas circulation channel in the rod body 3, and air holes are opened on the side wall of the middle part of the rod body 3. The gas circulation channel is connected; the passing mechanism 4 is arranged inside the rod body 3 to control the opening and closing of the air hole and the gas circulation channel; the sealing ring 5 is set on the rod body 3 to ensure the sealing between the rod body 3 and the drill pipe 1 The suspension ring 6 is connected to the end of the rod body 3, and the suspension ring 6 conflicts with the positioning ring 2 during the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com