Constant-temperature water mixing valve

A constant temperature mixing valve and valve body technology, applied in the valve details, valve device, valve shell structure, etc., can solve the problems of slow reaction speed of paraffin, affecting the use of mixing valve, temperature sensing failure, etc., to improve stability, Good application value, reduce the effect of overheating or overcooling of the outlet water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

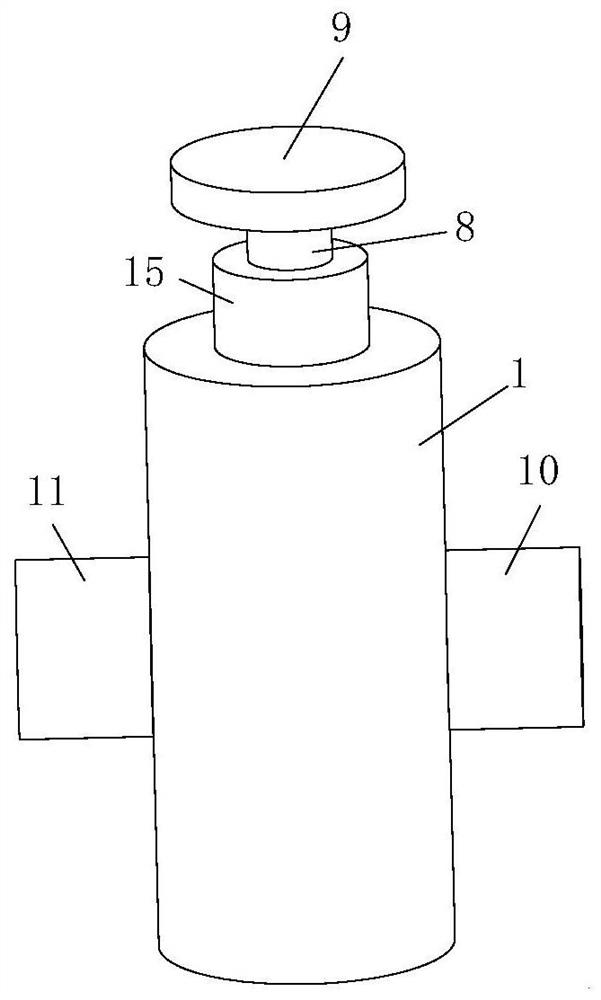

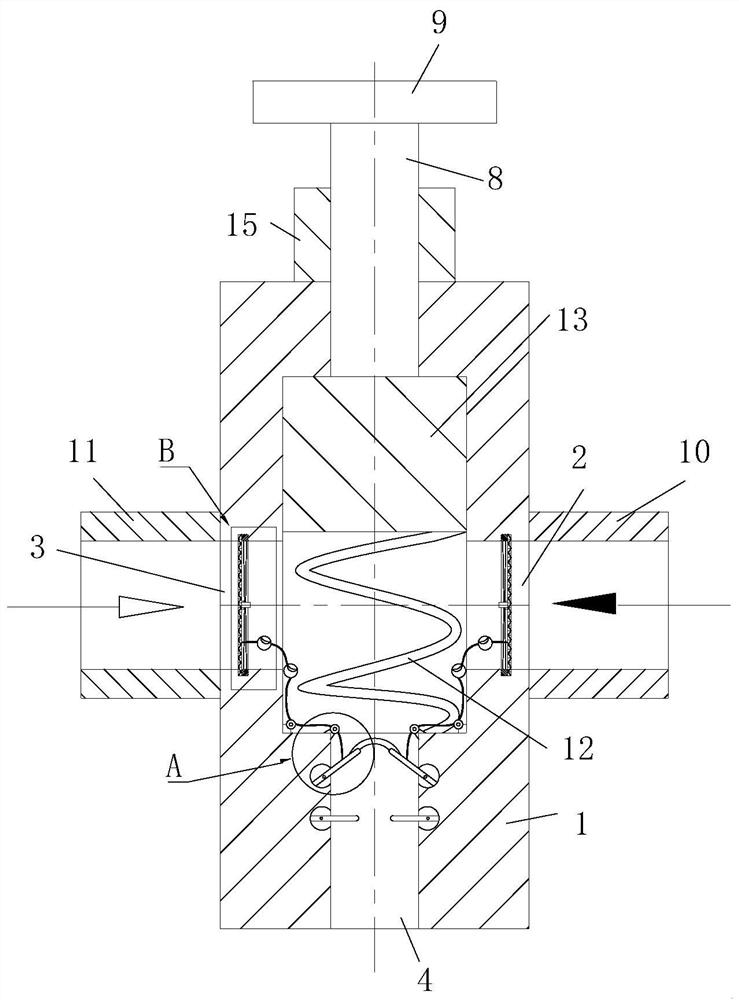

[0029] Attached below Figure 1-5 The present invention is further described with embodiment:

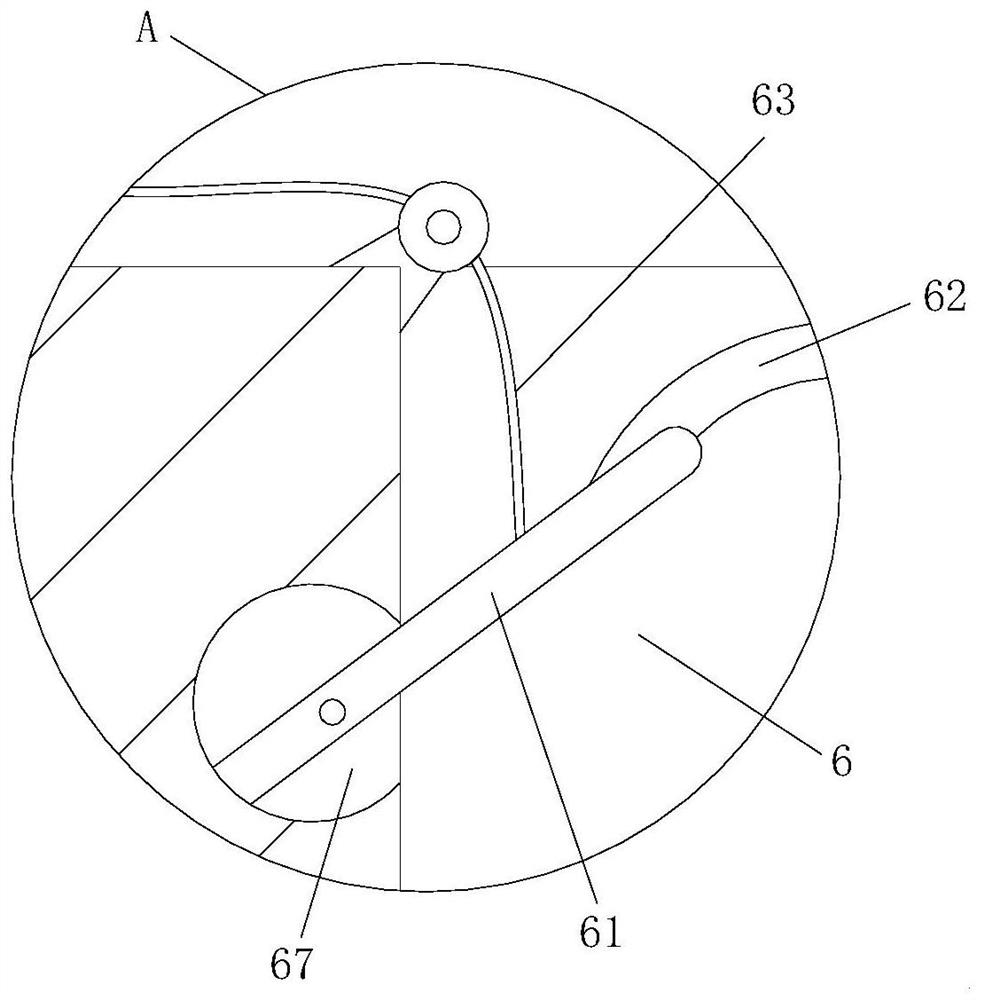

[0030] A thermostatic water mixing valve, comprising a valve body 1 and a valve stem 8, a cold water inlet 2 is arranged on one side of the valve body 1, a hot water inlet 3 is arranged on the other opposite side, and a water outlet 4 is arranged at the lower part of the valve body 1 , the valve stem 8 is slidingly installed on the top of the valve body 1, the upper end of the valve stem 8 protrudes from the valve body 1 and is fixedly connected with the adjusting handle 9, and the lower end of the valve stem 8 is fixedly connected with a sealing block 13, and the sealing block 13 It is connected with the inner wall of the valve body 1 through a memory spring 12, the cold water inlet 2 and the hot water inlet 3 are provided with a filter mechanism 5, and the water outlet 4 is provided with a vibration mechanism 6; the cold water inlet 2 and the hot water inlet The water inlet 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com