Mica capacitor with end head in complete monolithic structure, and preparation method thereof

A technology of capacitors and mica, which is applied in the direction of laminated capacitors, fixed capacitor electrodes, fixed capacitor leads, etc., can solve the problems of excessive capacity, large loss, high elimination rate, etc., achieve small tanδ value, improve hit rate, and easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

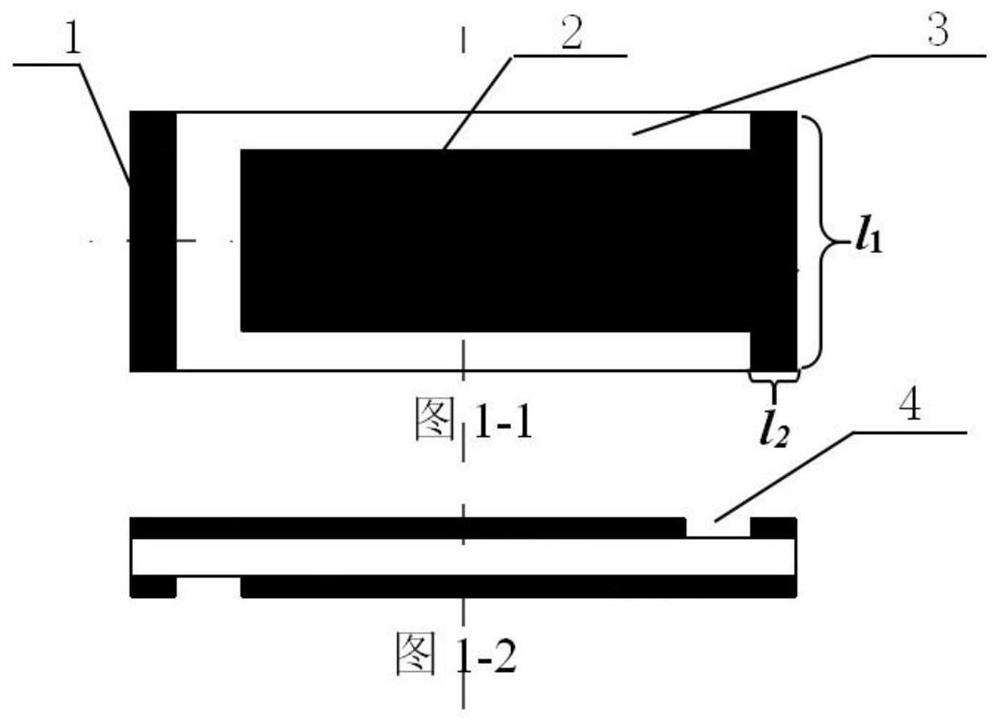

[0055] A method for preparing a mica capacitor with a complete monolithic structure at the end, comprising the following operations:

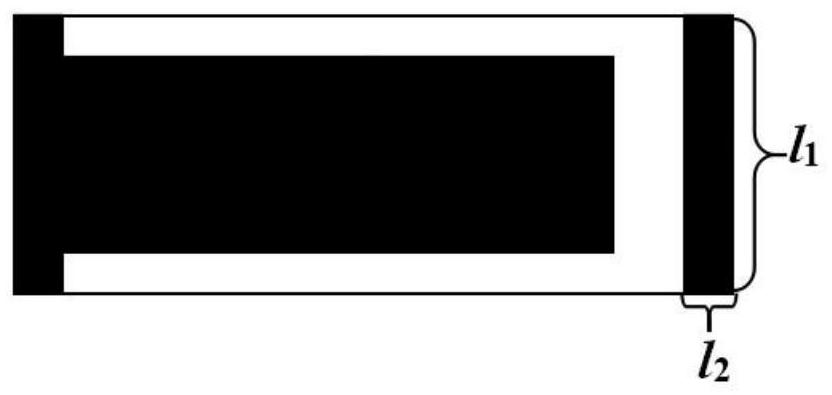

[0056] 1) Cut the mica sheet according to the required size and clean it, then print the large silver electrode layer and the small silver electrode layer symmetrically on both sides of the mica sheet through screen printing, and the height of the two ends is the same as that of the mica sheet equal in width;

[0057] After the silver electrode layer is printed, transfer the mica silver sheet to the heating plate, and dry it at a temperature of 170-230°C for 3-5 minutes;

[0058] 2) Spread the dried mica silver flakes flat on the transmission mesh belt of the tunnel sintering furnace, and transfer them from the furnace head at 400°C to the furnace tail at 600°C while sintering the mica silver flakes. The conveying / sintering time is 25~ 35min;

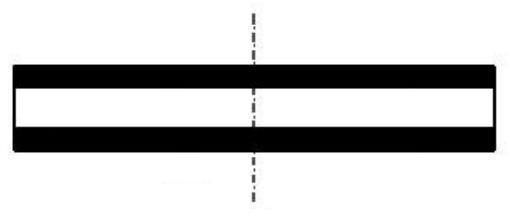

[0059] 3) When adjacent mica silver sheets are staggered and stacked, assemble the core group accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com