Outside-cabinet auxiliary guide rail device for floor type circuit breaker of switch cabinet

A cabinet floor-mounted, auxiliary guide rail technology, applied in switchgear, electrical components and other directions, can solve the problem of not adapting to installation sites of different heights, and achieve the effect of reducing construction costs, ensuring support strength, and facilitating assembly, disassembly and connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

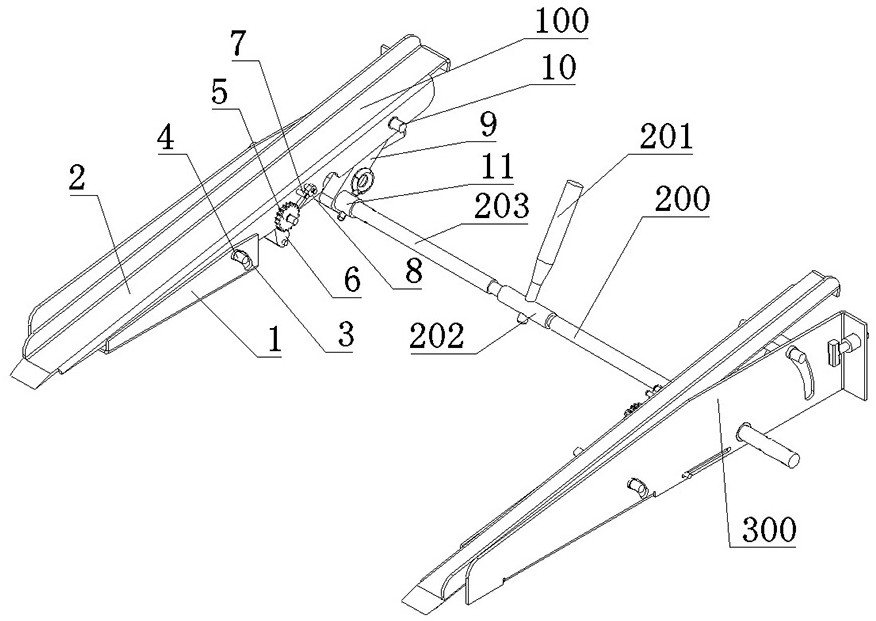

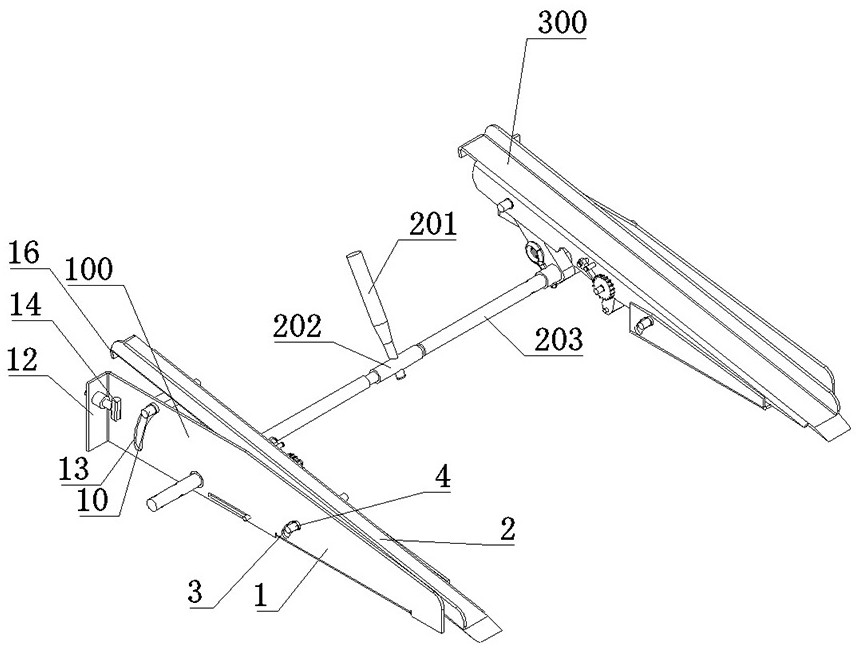

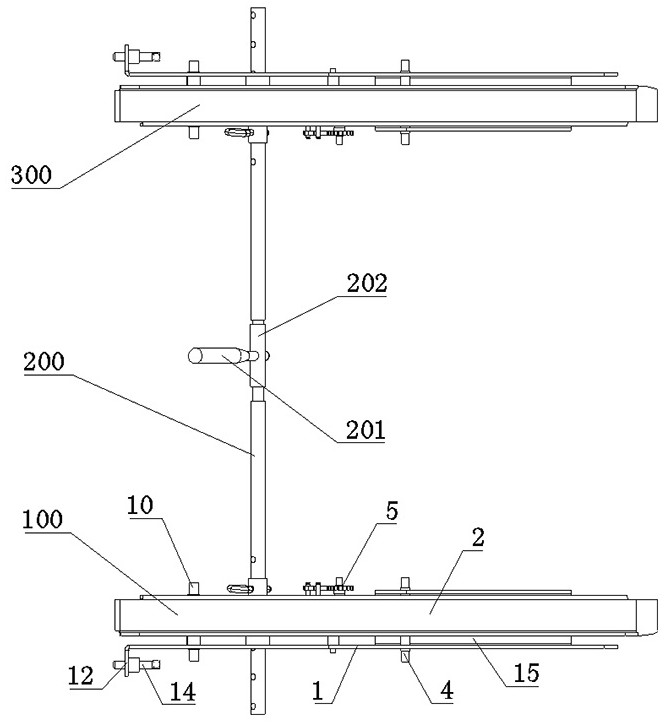

[0055] like Figure 1 to Figure 15 As shown, in this embodiment, the structure of the auxiliary guide rail device outside the cabinet for the floor-standing circuit breaker of the switch cabinet includes three parts: the left guide rail assembly 100, the right guide rail assembly 300 and the middle span assembly 200. These three parts are detachably assembled together , The guide rail assembly on both sides and the middle span assembly 200 can be disassembled as independent modules, which is convenient for transportation and portability, and is also convenient for assembly and molding.

[0056] The middle span assembly 200 here can conveniently adjust the span of the guide rail assembly on both sides to meet the requirements of different types of floor-mounted circuit breakers and improve the versatility. like Figure 15 As shown, the middle span assembly 200 specifically includes connecting rods 203 on both sides, and the connecting rods 203 on both sides are assembled toget...

specific Embodiment 2

[0074] The difference between it and Embodiment 1 mainly lies in that in Embodiment 1, the assembly of the middle span is adjustable. In this embodiment, while retaining the adjustable slope of the guide rails on both sides, a fixed-length intermediate span can also be used. In this case, only a single-width circuit breaker type can be used.

specific Embodiment 3

[0076] The main difference between it and Embodiment 1 is that in Embodiment 1, a middle span assembly is detachably installed between the guide rail assemblies on both sides, which can effectively improve the strength of the entire guide rail device. In this embodiment, if only relying on the assembly strength of the guide rails on both sides to meet the support strength requirements of the circuit breaker, the assembly in the middle span can also be omitted. At this time, the assembly positions of the guide rails on both sides can be arranged arbitrarily according to the actual span.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com