Tetra-functional long-chain branched ethylene-based polymers

A polymer, ethylene technology, applied in the field of tetrafunctional long-chain branched ethylene polymers, can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0194] h smax = Height of the scaled MWD at the point of maximum slope

[0195] pt1=S 最大 LogM value

[0196] pt2 = LogM value, where S 最大 The tangent intersects the x-axis

[0197] The MWD area measure is defined below, where A 高 Just the area where the MWD region falls off after the point of maximum slope. Second area measure A 尾部 is depicted in Figure 15 Small high MW area in and through from A 高 Evaluate by subtracting the area of the triangle.

[0198]

[0199] A 尾部 =A 高 -1 / 2(H smax ) 2 / S 最大 (51)

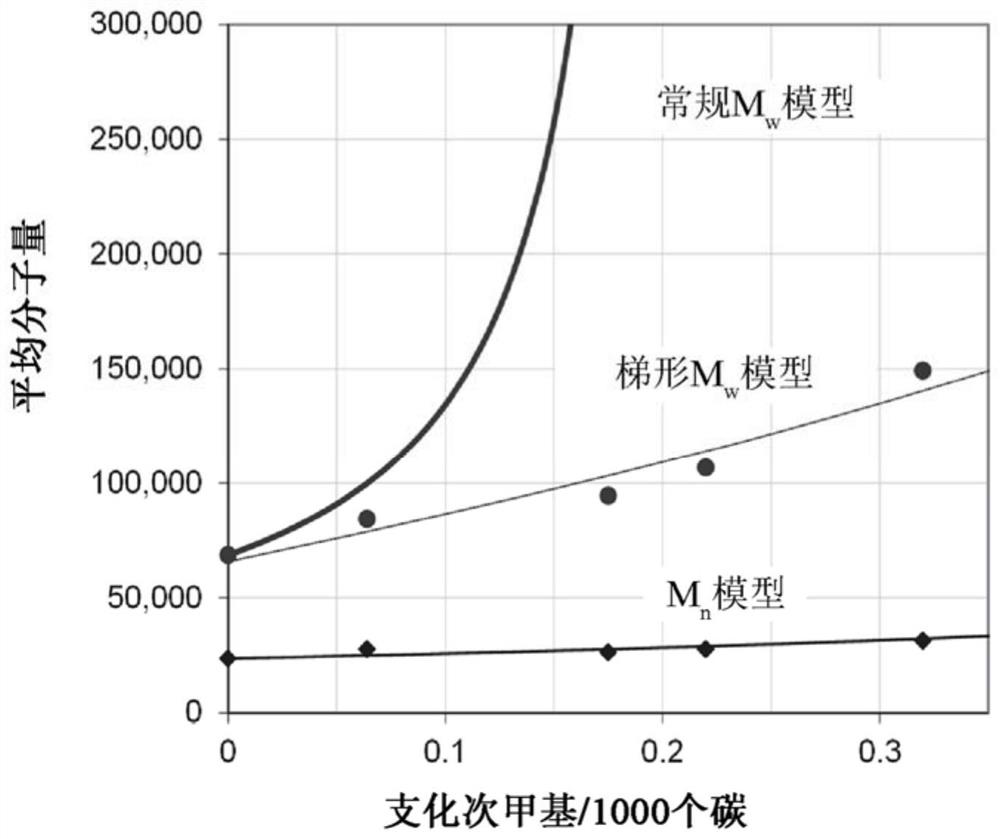

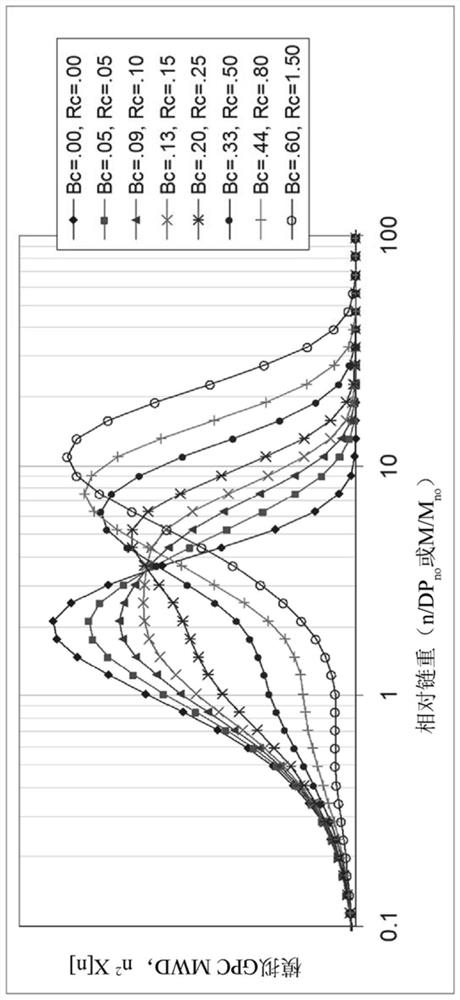

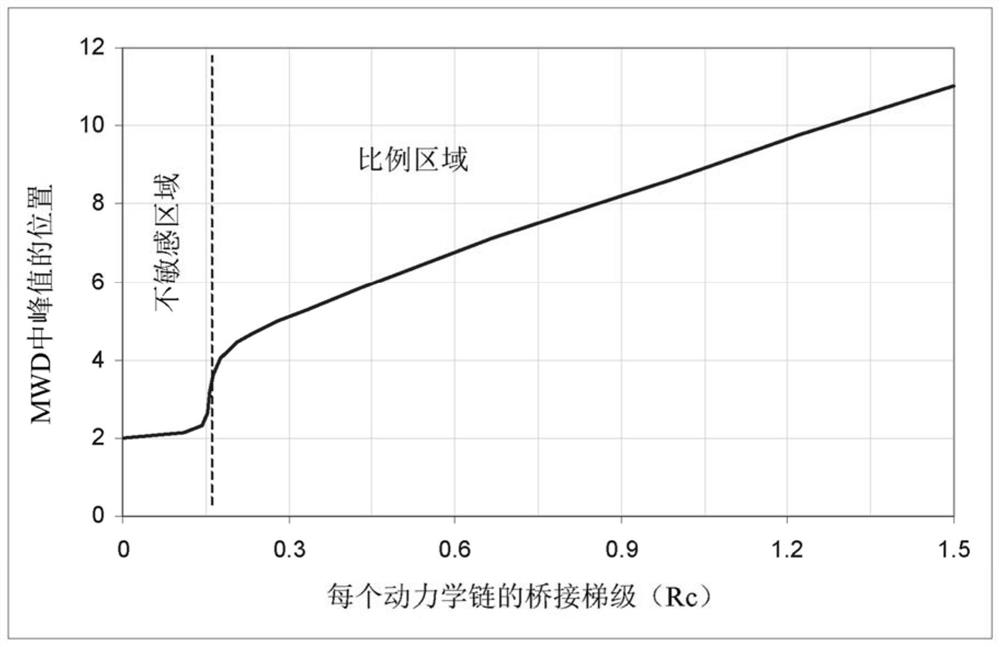

[0200] The area measure A was tested on the MWD model for "ladder branching" and conventional diene branching 高 and A 尾部 , where the results are plotted in Figure 16 , Figure 17 , Figure 18 ,with Figure 19 middle. The figure shows that by A 高 or A 尾部 The defined high MW area increases dramatically with increasing levels of conventional branching. However, the "trapezoidal branching" model predicts high MW area measures (A 高 or A 尾部 ) are hardl...

example

[0280] Tetrafunctional branching in the presence of various multichain catalysts and various dienes

[0281] The results of the small-scale polymerizations are summarized in Tables 3 to 7 (the experiments were in parallel polymerization reactors, PPR). The polymer results reported in Tables 3 to 7 were generated by polymerizing ethylene, octene and diene species in the presence of multi-chain catalysts and single-chain catalyst controls. The polymer results for each of Tables 3 through 7 are the product of various catalysts and diene species. The results in Table 3 are based on 3-methyl-1,4 in the presence of Comparative Catalyst C1 (Comp. - Polymer products of pentadiene, ethylene and octene. The results in Table 4 are based on 1,4-pentadiene, ethylene and octene in the presence of Catalyst 2 and Catalyst 4 ("Cat.4") Polymer product. The results in Table 5 are based on 1 in the presence of Comparative Catalyst C1, Catalyst 3 ("Cat.3"), Catalyst 5 ("Cat.5") and Catalyst 6 ("...

example 1

[0285] Example 1 - Tetrafunctional branching through 3-methyl-1,4-pentadiene

[0286] Table 3: Small scale polymerization (PPR) with 3-methyl-1,4-pentadiene as diene species.

[0287]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt strength | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com