A mobile fire extinguisher maintenance system and its application

A technology for maintenance system and fire extinguisher, which is applied in fire rescue and other directions to achieve the effect of improving efficiency, convenient and quick maintenance, and convenient detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

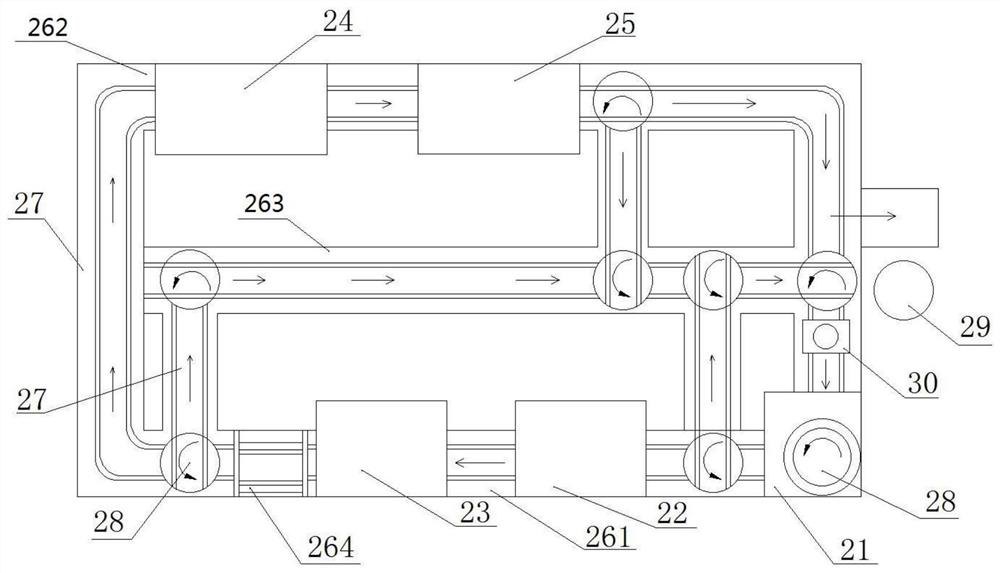

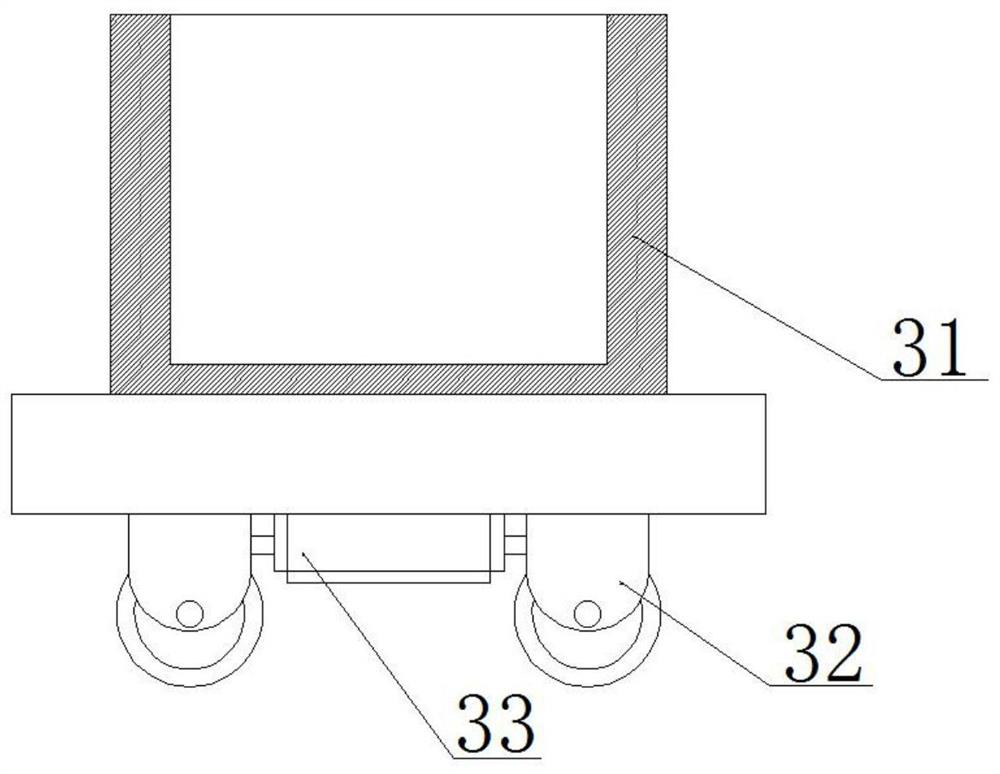

[0032] Such as Figure 1 to Figure 3 As shown, the mobile fire extinguisher maintenance system of this embodiment includes a mobile device 1, a maintenance device 2 installed on the mobile device 1, and a controller for controlling the maintenance device 2. The maintenance device 2 includes an appearance detection module 21, a disassembly module 22, The cylinder detection module 23, the filling module 24, the airtight detection module 25, and the transportation assembly for transporting the fire extinguisher to each module, the transportation assembly includes a clamping mechanism for clamping the fire extinguisher, a horizontal slide rail, a longitudinal slide rail 27, and a rotating disk 28. The clamping mechanism includes a rail car 30 that can move on the transverse slide rail, the longitudinal slide rail 27 and the rotating disc 28 and the magnetic attraction fixing part 31 arranged on the rail car 30. The rotating disc 28 is used to connect the transverse sliding rail and...

Embodiment 2

[0040] The invention also discloses the application of the mobile fire extinguisher maintenance system, which includes the following steps:

[0041] S1. Move the mobile device to the area where fire extinguisher maintenance is required; drive the truck to the community to be inspected;

[0042] S2. Collect the fire extinguishers in the area and observe their appearance manually. If the fire extinguishers with obvious defects in appearance do not enter the inspection device, put the fire extinguishers to be tested into the inspection device;

[0043] S3. The maintenance device performs automatic maintenance on the fire extinguisher; the automatic maintenance process includes:

[0044] A1. Check the appearance of the fire extinguisher, use a fixed camera and an infrared flaw detection camera to scan and take pictures of the fire extinguisher, and the control system analyzes its surface; unqualified products are sent to the waste channel, and qualified products are sent to the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com