Seed potato dicing machine

A cutting machine and potato technology, applied in rhizome seed cutting machine, seed and rhizome treatment, metal processing, etc., can solve the problems of manpower and material resources, not strict disinfection, poor potato quality, etc., achieve mechanization and efficiency, and improve operation Efficiency, convenient storage and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the examples.

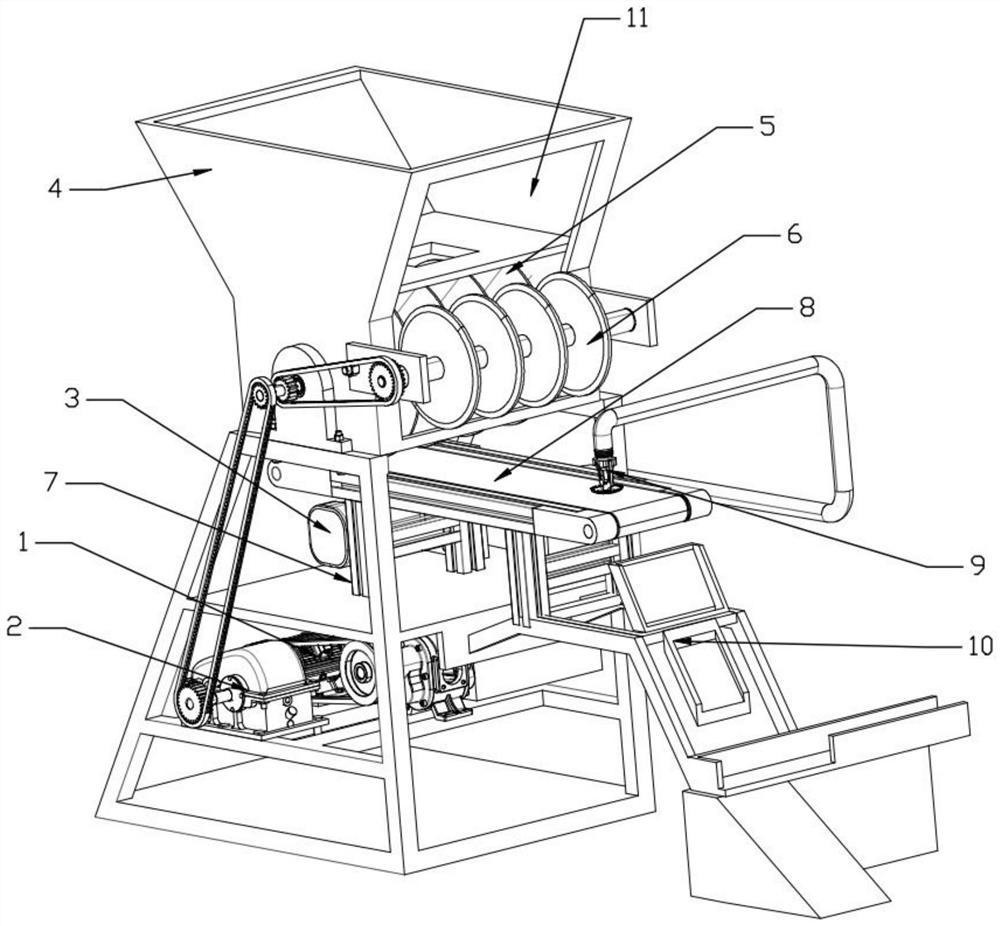

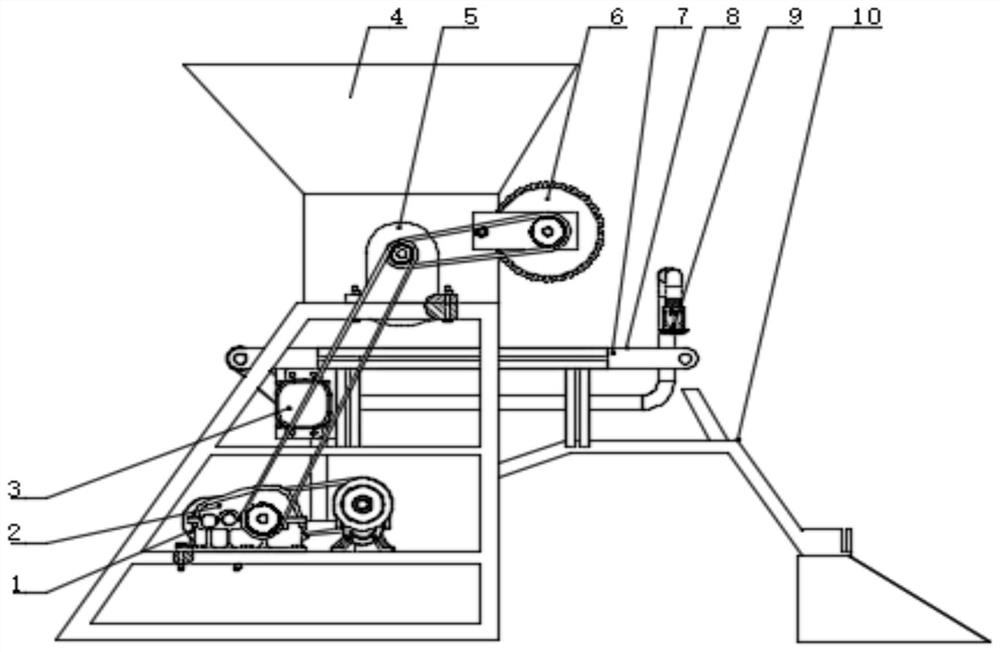

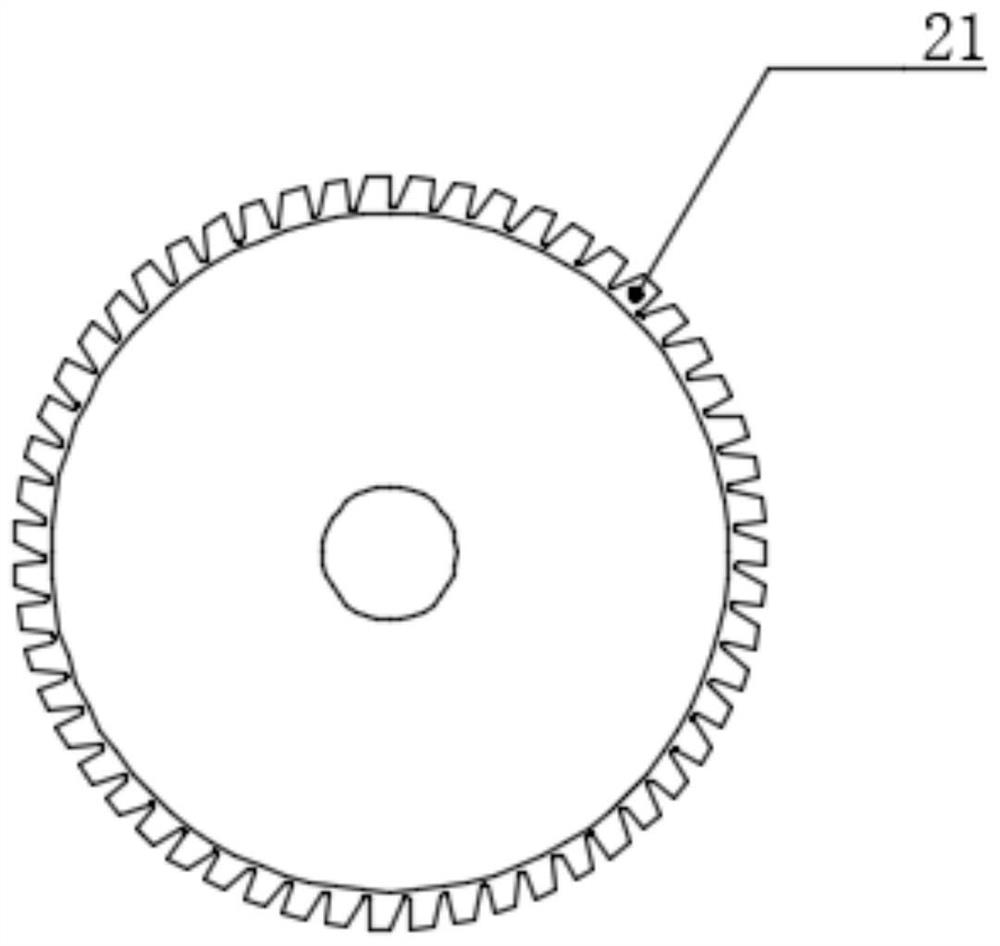

[0020] When the present invention is specifically implemented, a seed potato cutting machine includes a frame body, and the frame body includes upper and lower layers. The upper frame body is fixed with a transmission device 7, and the lower frame body A motor 1 is fixed inside, the output shaft end of the motor 1 is connected to the secondary reduction device 2, the upper end of the main body of the frame is provided with a lower hopper 4, and the inner bottom of the lower hopper 4 is provided with a feeding port, so The front side of the lower hopper 4 is provided with a transparent baffle 11, and a cylindrical drum 5 is arranged below the feed inlet. Disc cutter 6, the edge of the disc cutter 6 is provided with cutting blades 21 uniformly distributed along its circumference, several disc cutters 6 and several cylindrical drums 5 are arranged alternately, the disc The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com