Orbital ring rotary flapping wing power device

A technology of power device and orbital ring, which is applied in the field of orbital ring rotating flapping wing power device, can solve the problems of impossibility of large-scale promotion and use, collision between propeller and surrounding objects, ignition of surrounding objects, etc., to achieve the expansion and reduction of blades Small area, low cost, and the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

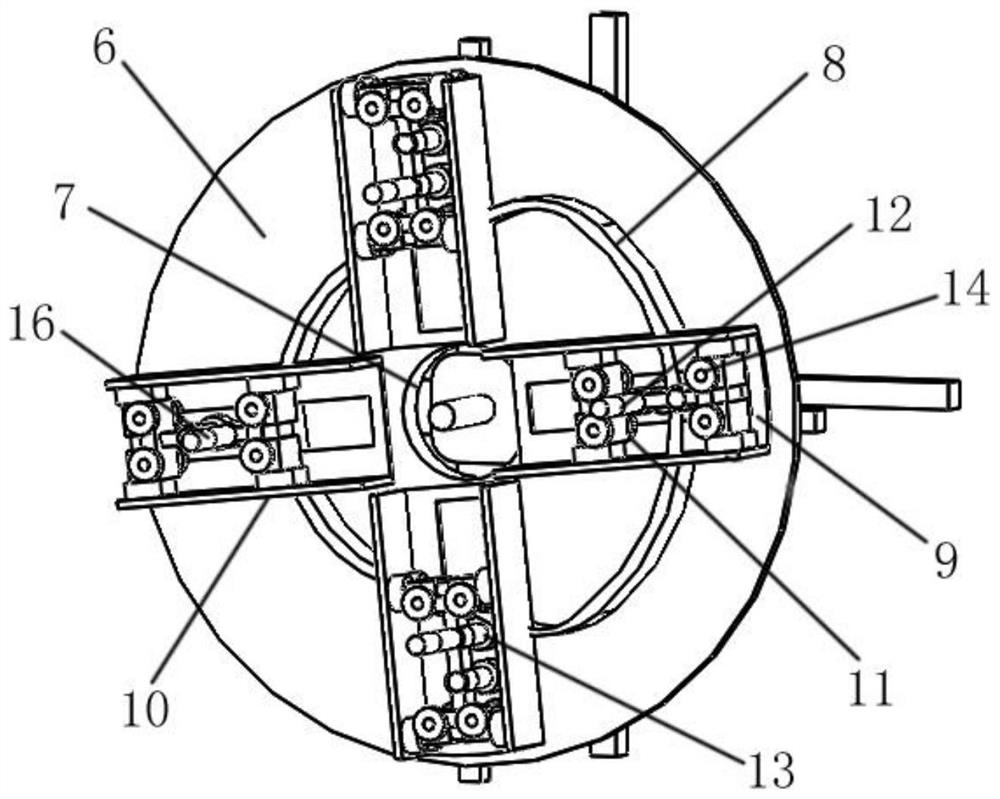

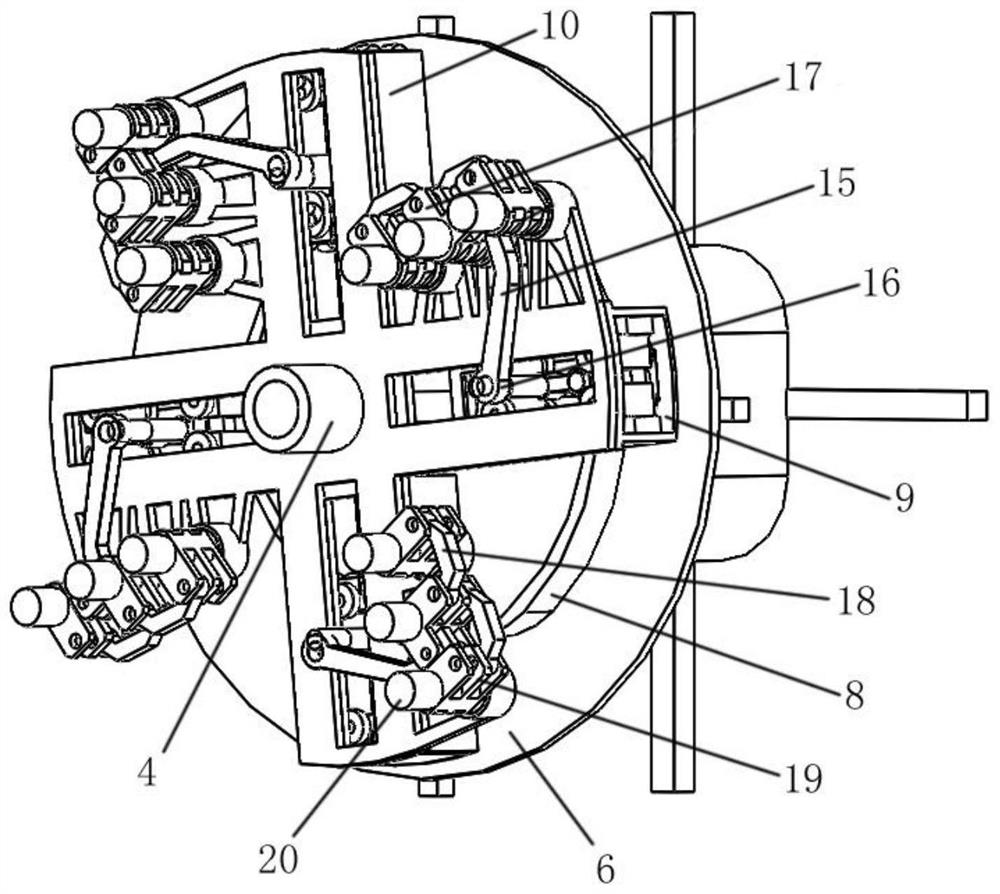

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

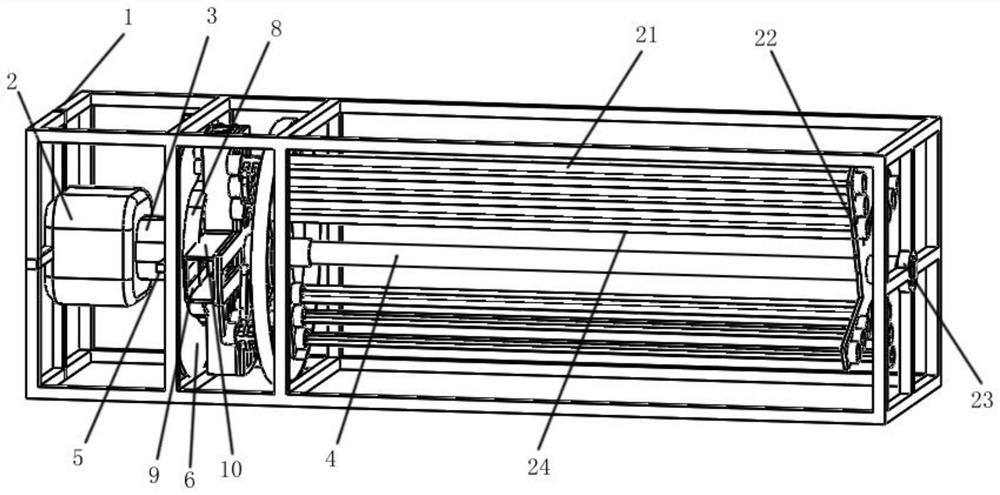

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the orbital ring rotary flapping wing power device of the present invention consists of a support 1, an engine 2, a coupling 3, a main shaft 4, an orbital ring support frame 5, an orbital ring connector 6, an orbital ring connecting bearing 7, a core orbital ring 8, Sliding sleeve 9, sliding sleeve support 10, slider 11, slider shaft 12, slider shaft bearing 13, small pulley 14, active rocker arm 15, active rocker arm bearing 16, central axis connection block 17, driven rocker arm 18, It consists of a shaft connection block 19, a blade distribution wheel 20, a blade 21, a blade bracket 22, a blade distal bearing 23, and a segmented self-assembled fan blade 24.

[0023] Among them, the engine 2 is fixed on the bracket 1, the engine rotating shaft is connected with the coupling 3, the coupling 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com