An electric forklift universal cross shaft lead screw lifting gantry system

A technology of electric forklifts and cross shafts, applied in the direction of lifting devices, etc., can solve problems such as lifting and breaking of ball screws, and achieve the effects of reducing energy consumption, convenient maintenance, and low system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

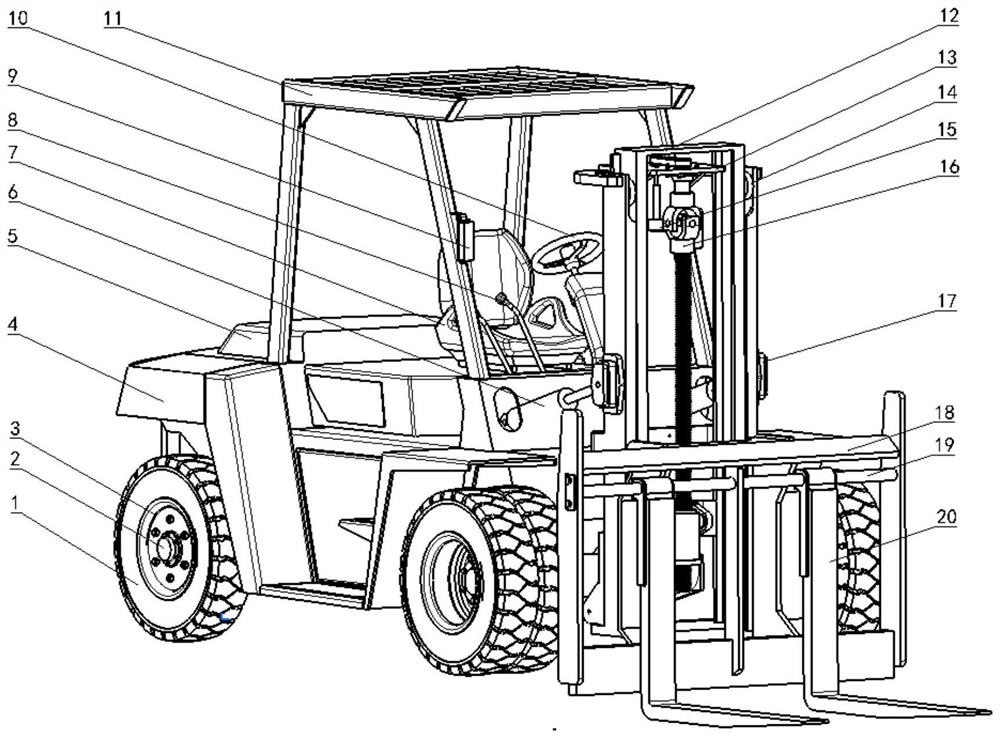

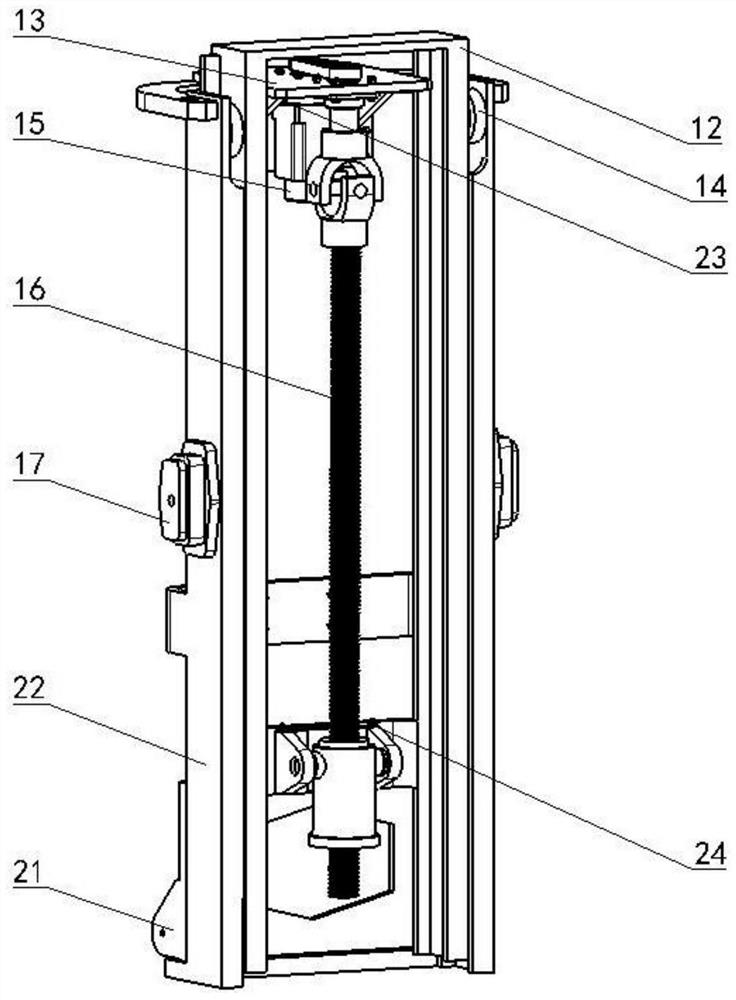

[0027] An electric forklift universal cross shaft lead screw lifting mast system, such as Figure 2 to Figure 6 shown,

[0028] It includes an inner gantry 12, an outer gantry 22, and a universal screw drive system 16. The inner gantry 12 and the outer gantry 22 are connected by an outer gantry guide roller 14 arranged on the outer gantry 22; The gantry 22 is connected with the forklift body 5 through the pitching hinged fixer 17, the pitching electric screw 6 and the gantry connecting plate 21, so as to realize the lifting and lowering of the gantry system;

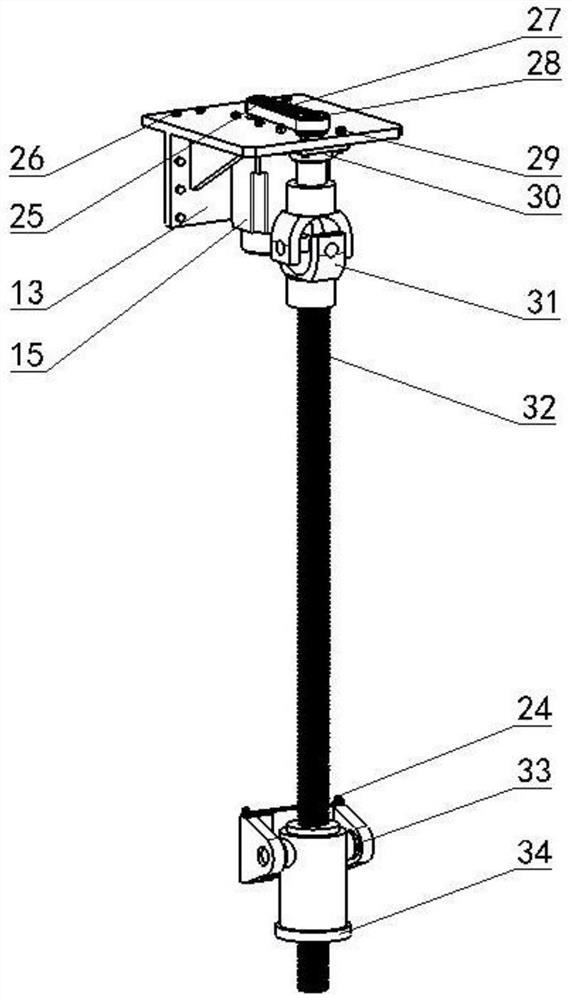

[0029] The universal screw power transmission system 16 includes a top fixed bracket 13, a lifting gear motor 15, a motor end synchronous pulley 25, a screw end synchronous pulley 28, a synchronous toothed belt 27, and a universal cross shaft coupling. The assembly 31, the ball screw 32, the center shaft positioning sleeve 33 and the ball screw nut 34, the top fixing bracket 13 is arranged on the lower side of the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com