3D curved screen protective film and preparation method thereof

A technology of protective film and curved screen, which is applied in the direction of pressure-sensitive film/sheet, film/sheet release coating, film/sheet adhesive, etc. Curved surface R corner edge warping, difficult screen fit and other problems, to achieve high wear resistance and flexibility, low production cost, strong protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

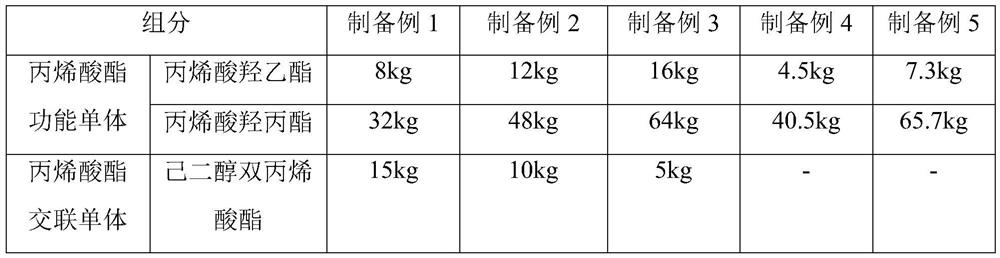

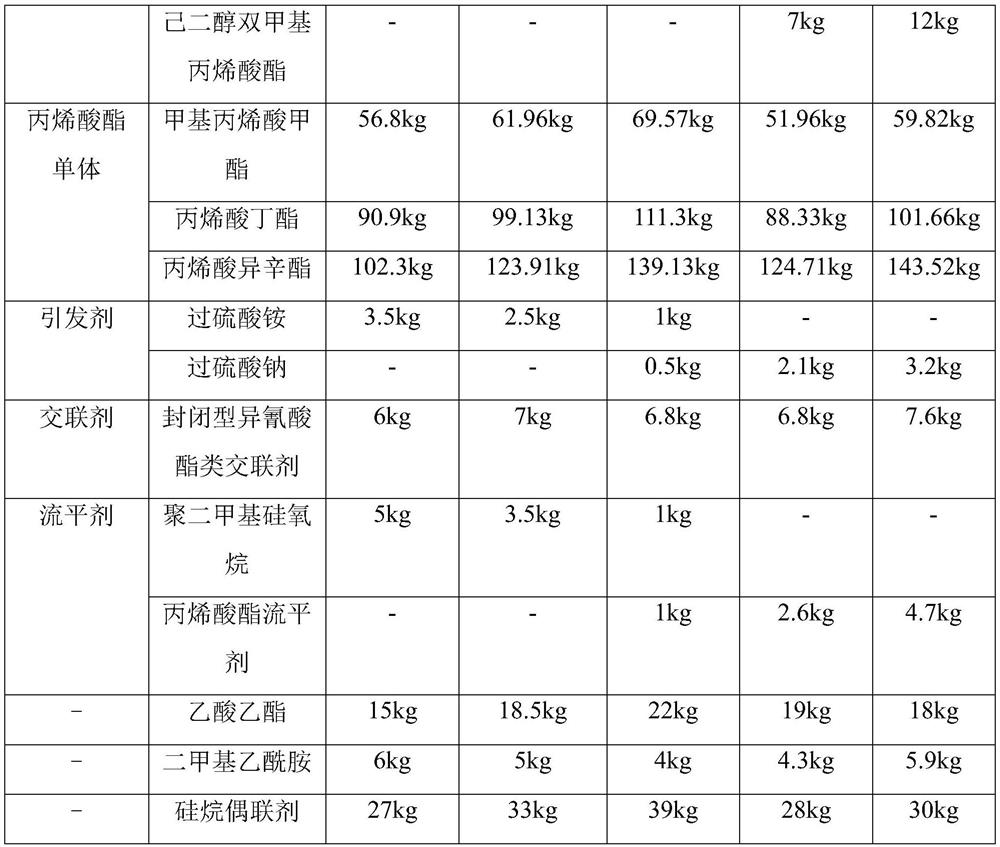

preparation example 1

[0054] Modified acrylic pressure sensitive adhesive is prepared by the following method:

[0055] At a temperature of 30°C, firstly stir and mix acrylate functional monomer, acrylate crosslinking monomer, acrylate monomer, initiator, crosslinking agent, leveling agent and ethyl acetate for 5 minutes, and then add dimethyl Acetamide was stirred and mixed for 10 minutes, and finally a silane coupling agent was added and stirred and mixed for 30 minutes to obtain a modified acrylic pressure-sensitive adhesive.

preparation example 2

[0057] Modified acrylic pressure sensitive adhesive is prepared by the following method:

[0058] At a temperature of 35°C, stir and mix acrylate functional monomer, acrylate crosslinking monomer, acrylate monomer, initiator, crosslinking agent, leveling agent and ethyl acetate for 7.5 minutes, and then add two The methyl acetamide was stirred and mixed for 12.5 minutes, and finally the silane coupling agent was added and stirred and mixed for 35 minutes to obtain a modified acrylic pressure-sensitive adhesive.

preparation example 3

[0060] Modified acrylic pressure sensitive adhesive is prepared by the following method:

[0061] At a temperature of 40°C, firstly mix acrylate functional monomer, acrylate cross-linking monomer, acrylate monomer, initiator, cross-linking agent, leveling agent and ethyl acetate for 10 minutes, then add dimethyl Acetamide was stirred and mixed for 15 minutes, and finally a silane coupling agent was added and stirred and mixed for 40 minutes to obtain a modified acrylic pressure-sensitive adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com