Method for producing ultralow-sulfur steel by using LF and VD duplex technology

A dual process, ultra-low sulfur technology, applied in the field of steelmaking, can solve the problems of high smelting cost, complex process route, and great impact on continuous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

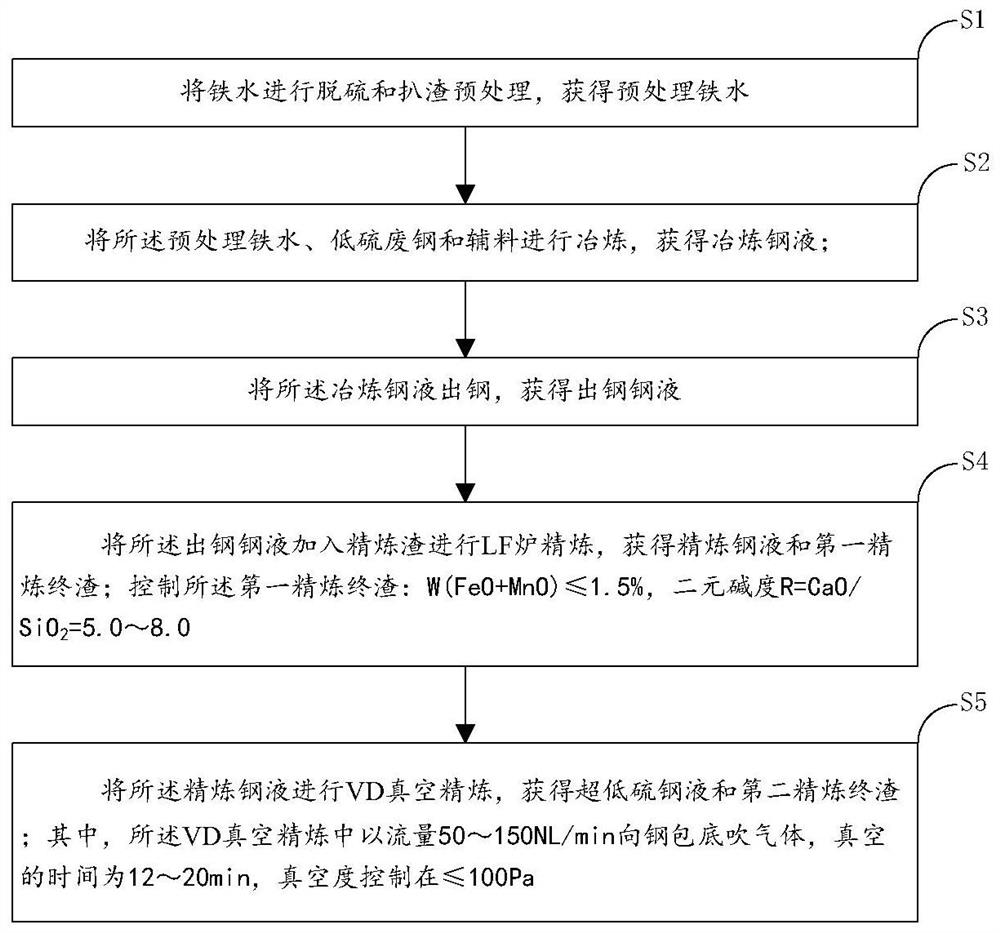

Method used

Image

Examples

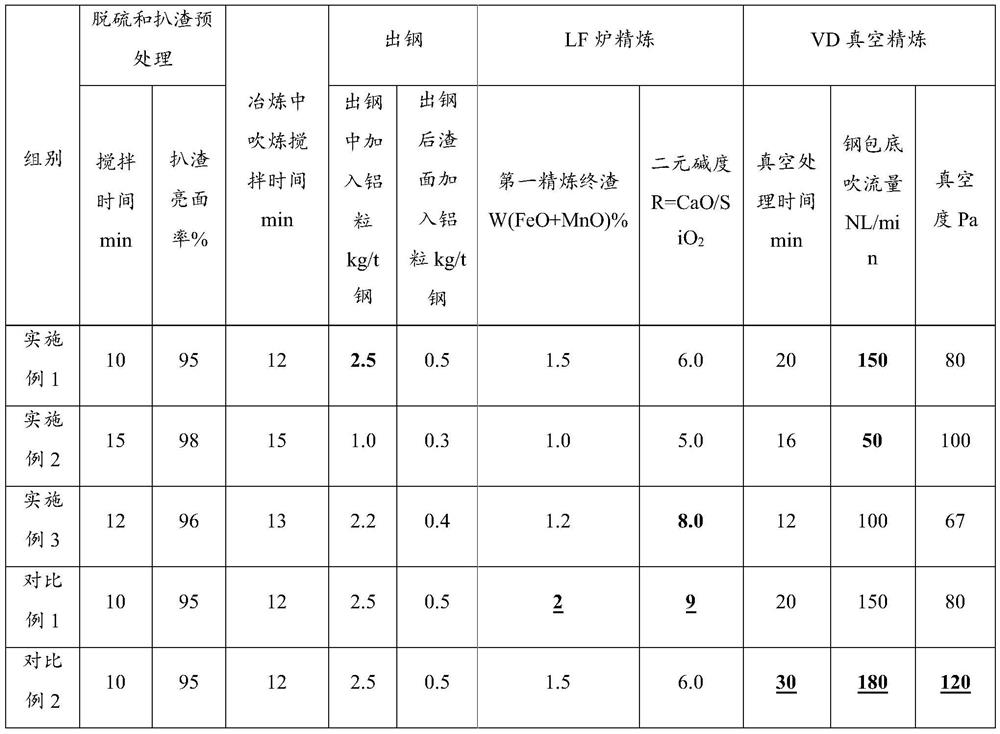

Embodiment 1

[0061] The steel type is X60MS, and the target sulfur content of the finished product is less than 0.0010%. The process route adopted is: KR desulfurization pretreatment—converter—LF furnace refining—VD refining—continuous casting.

[0062] Step S1, the molten iron is subjected to KR desulfurization pretreatment, the stirring time is controlled at 10 minutes, and then the slag removal pretreatment is carried out (the slag removal bright surface rate is 95%), and the pretreated molten iron with S=0.0015% is obtained;

[0063] Step S2, converter smelting: using low-sulfur steel scrap and auxiliary materials, controlling the sulfur content of the scrap steel to 0.0050%, and the sulfur content of the auxiliary materials to 0.0040%, and controlling the blowing and stirring time in the smelting to 12 minutes to obtain molten steel with an S content of 0.0060%; Aluminum strong deoxidation is used for tapping, and the addition amount is 2.5kg / t steel; after tapping, aluminum particles ...

Embodiment 2

[0068] Steel type Q345R-HIC, the target sulfur content of the finished product is less than 0.0010%, the adopted process route is: KR desulfurization pretreatment-converter-LF furnace refining-refining-continuous casting.

[0069] Step S1, the molten iron is subjected to KR desulfurization pretreatment, the stirring time is controlled at 15 minutes, and then the slag removal pretreatment is carried out (the slag removal bright surface rate is 98%), and the pretreated molten iron with S=0.001% is obtained;

[0070] Step S2, converter smelting: using low-sulfur scrap steel and auxiliary materials, controlling the sulfur content of the scrap steel to 0.0050% and the sulfur content of the auxiliary materials to 0.0030%, and controlling the blowing and stirring time in the smelting to 15 minutes to obtain molten steel with an S content of 0.0050%; Aluminum strong deoxidation is used for tapping, and the addition amount is 1.0kg / t steel; after tapping, aluminum particles are added to...

Embodiment 3

[0075] The steel grade is A516Gr.60-HIC, the target sulfur content of the finished product is less than 0.0010%, and the adopted process route is: KR desulfurization pretreatment—converter—LF furnace refining—VD refining—continuous casting.

[0076] Steel type Q345R-HIC, the target sulfur content of the finished product is less than 0.0010%, and the adopted process route is: KR desulfurization pretreatment—converter—LF furnace refining—VD refining—continuous casting.

[0077] Step S1, the molten iron is subjected to KR desulfurization pretreatment, the stirring time is controlled at 12 minutes, and then the slag removal pretreatment is carried out (the slag removal bright surface rate is 96%), and the pretreated molten iron with S=0.0015% is obtained;

[0078]Step S2, converter smelting: using low-sulfur steel scrap and auxiliary materials, controlling the sulfur content of the scrap steel to 0.0040% and the sulfur content of the auxiliary materials to 0.0040%, and controlling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com