Additive manufacturing smelting furnace

An additive manufacturing and smelting furnace technology, applied in the field of additive manufacturing, can solve the problems of waste of granular powder and excessive flue gas, and achieve the effects of speeding up smelting, improving stirring and mixing, and facilitating scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

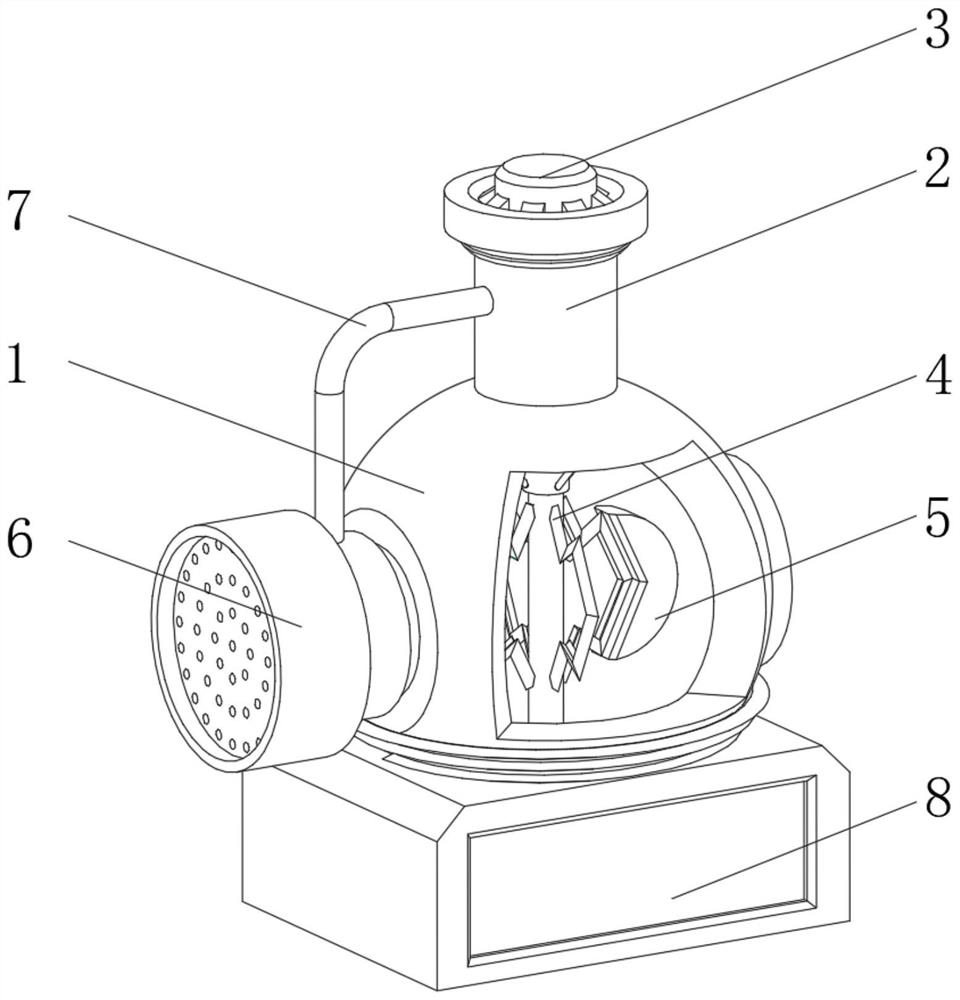

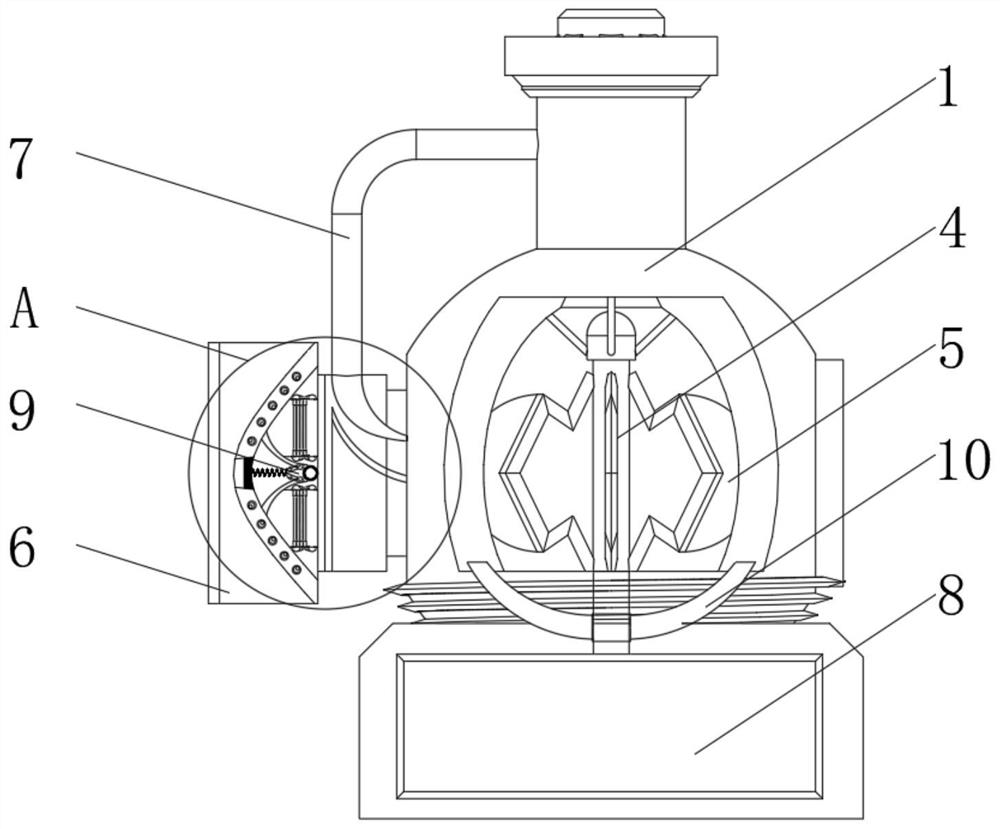

[0033] see Figure 1-3 , the present invention provides a technical solution: a smelting furnace for additive manufacturing, specifically comprising:

[0034] A smelting furnace 1, the smelting furnace 1 has a melting furnace body, and a smelting furnace body tube 2 arranged on the top, and a top exhaust head 3 is arranged on the top of the smelting furnace 1;

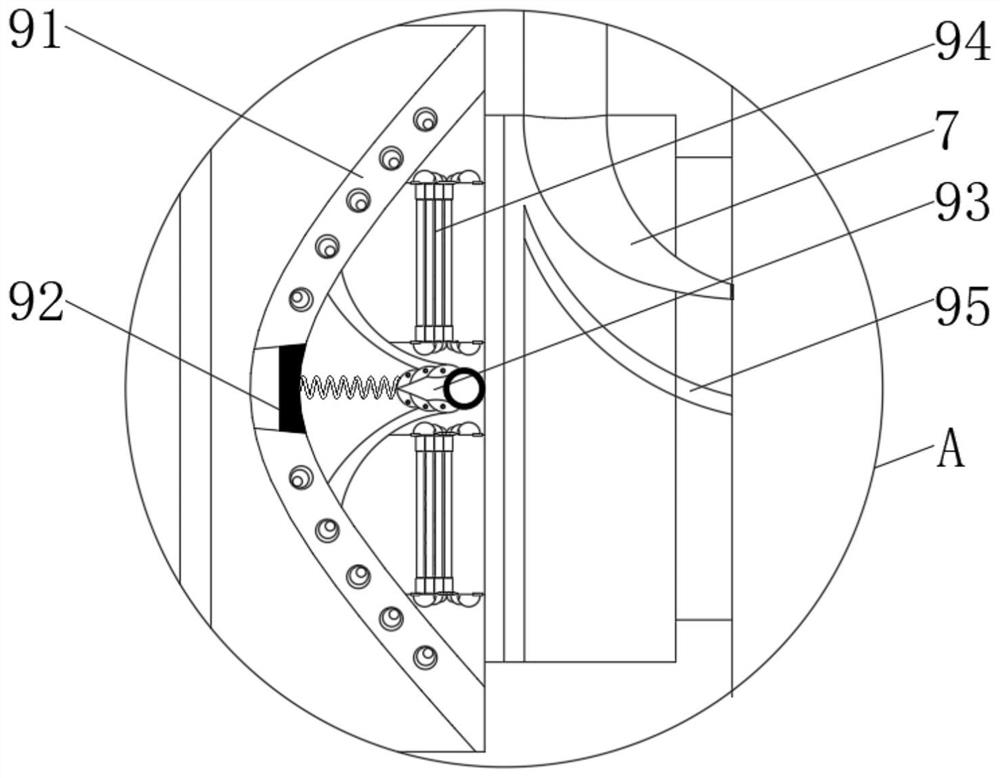

[0035] Smelting gas injection head 6, the smelting gas injection head 6 has a gas injection head body, and a gas return pipe 7 arranged above the smelting gas injection head 6, the upper and lower ends of the gas return pipe 7 communicate with the top smelting furnace body pipe 2 respectively;

[0036] A melting furnace base 8, the melting furnace base 8 has a base body, and a melting furnace installation seat arranged above the melting furnace base 8, and a driving mechanism is arranged inside the melting furnace base 8, and the melting furnace 1 also includes:

[0037] An inner smelting rotator 4, the inner smelting...

Embodiment example 2

[0042] On the basis of implementation case 1, please refer to Figure 1-6 , the present invention provides a technical solution: the side device 5 includes a fan-shaped frame 51, an arc-shaped scraper 52 is arranged on the outside of the fan-shaped frame 51, and an elastic telescopic rod 53 is arranged between the arc-shaped scraper 52 and the fan-shaped frame 51. A connection spring 54 is provided between the scraper 52 and the inner side of the sector frame 51 .

[0043] Both sides of the arc-shaped scraper 52 are provided with heating rollers 56, both sides of the arc-shaped scraper 52 are provided with horn contact pieces, both sides of the fan-shaped frame 51 are provided with electrical terminals 55, and the horn contact plates and electrical terminals 55 corresponds to the setting.

[0044]The heating roller part 56 includes a heating column, and a heating ball is installed on the top of the heating column. The heating roller part 56 is electrically connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com