Adiabatic internal combustion engine combustion system based on adiabatic combustion chamber and Miller cycle

A Miller cycle, combustion system technology, applied in combustion engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of easy peeling off of thermal insulation coating, low thermal efficiency, deflagration, etc., to improve effective thermal efficiency, improve thermal efficiency, guarantee The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

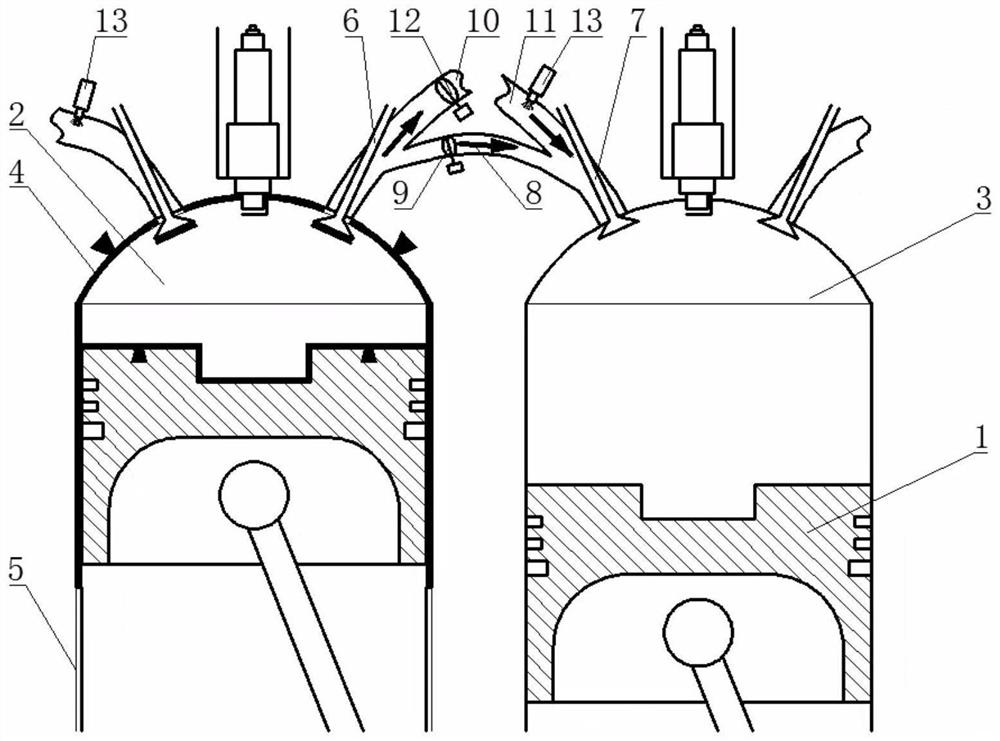

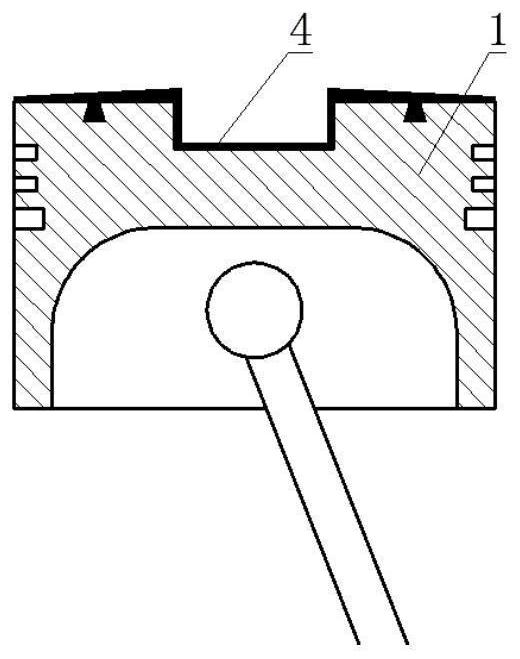

[0049] Taking a 4-cylinder 4-stroke gasoline engine as an example, it is assumed that the firing sequence of the engine is the commonly used 1-3-4-2, but the present invention is not limited to this case. Among them, 1-cylinder and 4-cylinder are set as adiabatic combustion chamber 2, and 2-cylinder and 3-cylinder are set as common combustion chamber 3. The working process of the engine is: intake process - compression process - work process - exhaust process. Since the firing sequence of each cylinder is commonly used 1-3-4-2, that is, 2-1-3-4, when the 1-cylinder piston 1 is in the intake stroke, the 2-cylinder piston 1 is in the compression stroke. Next, a dual-cylinder system composed of 1-2 cylinders is taken as an example to introduce the specific implementation of the present invention.

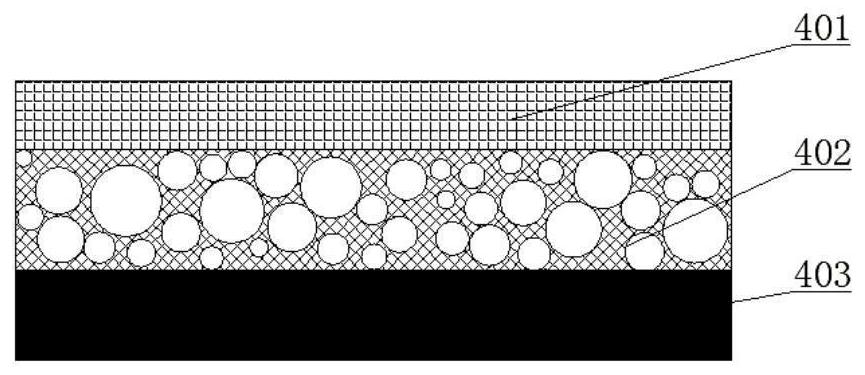

[0050] Such as figure 1 As shown, the exhaust passage of the adiabatic combustion chamber 2 is divided into an exhaust air passage 10 and a heat dissipation air passage 8 . Common c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com