Drying device for drying in chlorine ether rubber production

A drying device and rubber technology, applied in the directions of drying gas arrangement, drying, drying machine, etc., can solve the problems of poor safety, time-consuming and laborious drying process of chloroether rubber, poor drying effect, etc., and achieve drying speed. Fast, highly adjustable, good drying temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing, but the present invention is not limited to following description content:

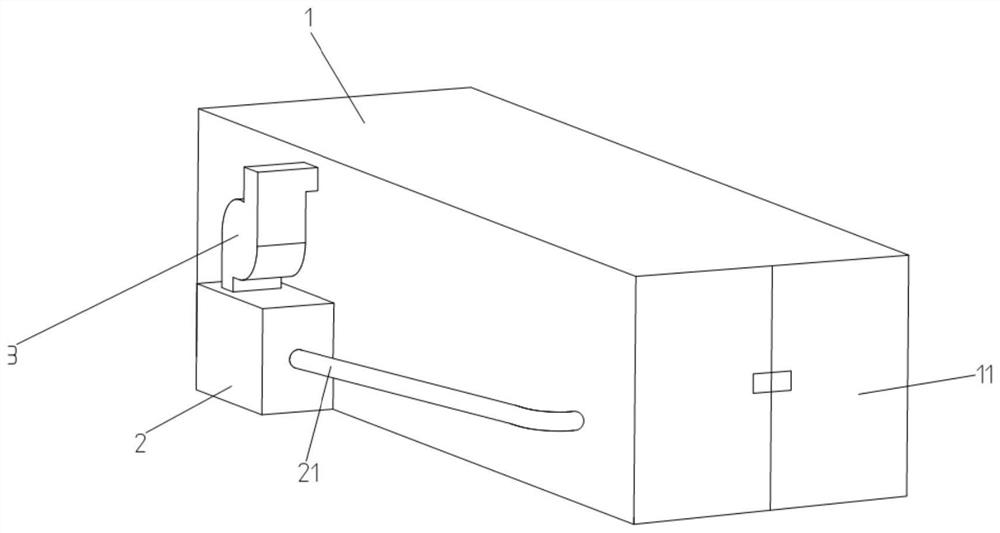

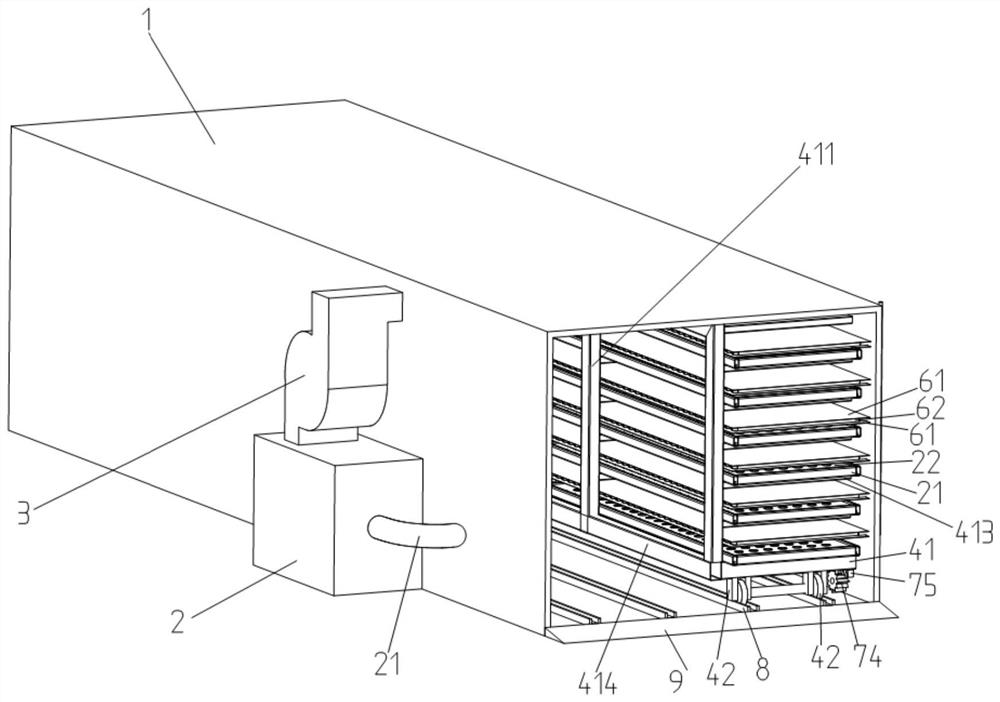

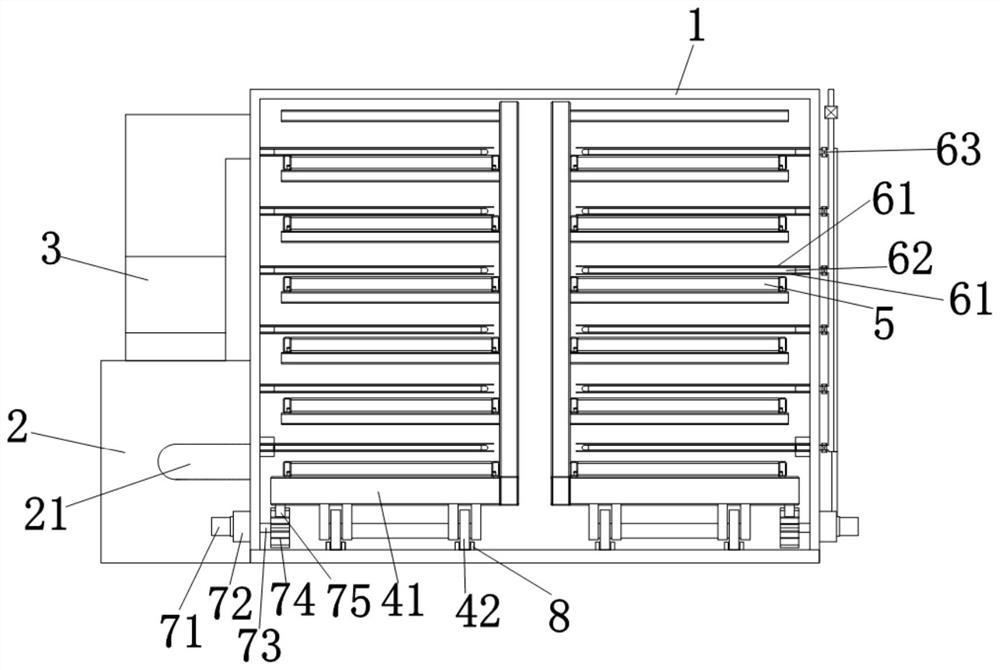

[0030] see Figure 1-4 , a drying device for the production of chlorine rubber, comprising a drying room 1, a drying box 2 is arranged on one side of the drying room 1, a fan 3 is fixed on the drying box 2, and the air inlet pipe of the fan 3 It communicates with the gas circulation outlet provided on the rear end side wall of the drying room 1, the exhaust pipe of the fan 3 communicates with the air inlet of the drying box 2, and the exhaust port of the drying box 2 passes through The gas pipeline 21 communicates with the gas circulation inlet provided on the front side wall of the drying room 1, and two drying mechanisms are symmetrically arranged on both sides of the drying room 1, and the drying mechanisms include a drying car 4, a drying Dry sieve 5, heating device 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com