Cold-rolled silicon steel quality defect prediction method based on neural network

A quality defect, cold-rolled silicon steel technology, applied in the field of cold-rolled silicon steel, can solve problems such as no defects, defects, etc., and achieve the effect of overcoming technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

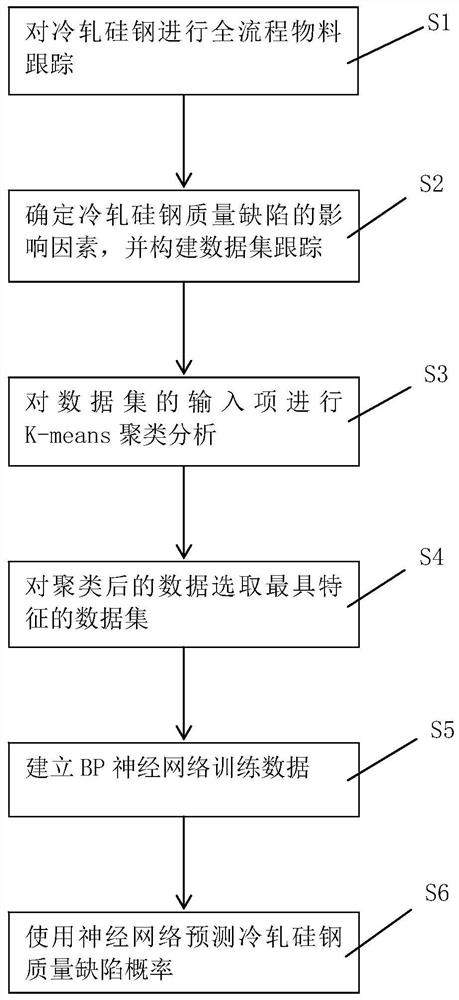

[0027] Such as figure 1 Shown, a kind of cold-rolled silicon steel quality defect prediction method based on neural network, it may comprise the following steps:

[0028] S1: Carry out the whole-process material tracking of cold-rolled silicon steel, complete the process data collection of each unit that the steel coil has experienced, and the collection of silicon steel quality defect results, and through the length mapping between the units, obtain the length and position of each unit corresponding to the raw materials. Process parameters and quality defect results at the location. Among them, the units may include normalized pickling units, rolling mills, continuous annealing coating units, recoiling units and packaging units, etc.

[0029] S2: Determine the influencing factors of the quality defects of cold-rolled silicon steel, and construct a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com