Steel sheet

A steel plate and chemical composition technology, which is applied in the field of high-strength steel plate and its manufacturing, can solve the problems of low productivity and achieve the effect of high strength and hydrogen embrittlement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

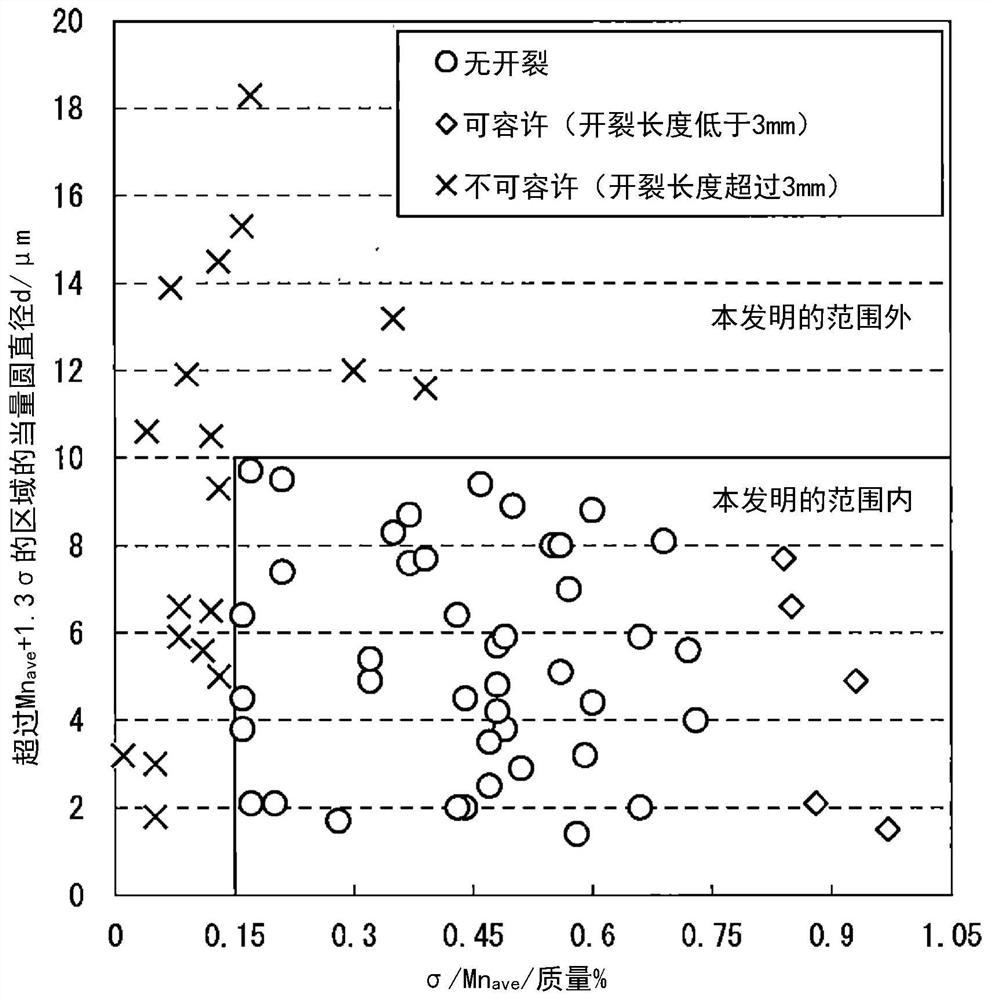

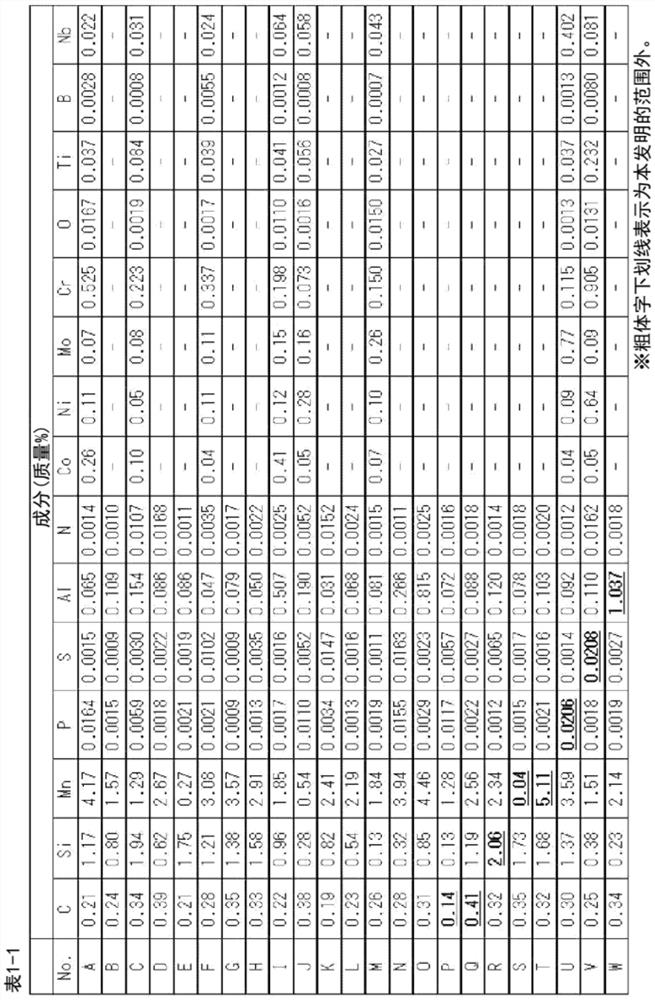

[0294] Steels having the chemical compositions shown in Table 1 were melted to cast billets. This steel slab was inserted into a furnace heated to 1220° C., held for 60 minutes for homogenization treatment, taken out into the air, and hot-rolled to obtain a steel plate with a plate thickness of 2.8 mm. In the hot rolling, the finish rolling was performed seven times in total, and among them, three rolling passes with a rolling reduction exceeding 20% were given. In addition, the pass time between each rolling pass for which a rolling reduction of 20% or more is given in the finish rolling and the preceding rolling pass of each rolling pass was set to 0.6 seconds. The start temperature of finish rolling is 1070°C, and the end temperature is 890°C. After 2.2 seconds after finish rolling, it is cooled by water cooling, and cooled to 580°C at an average cooling rate of 35.0°C / s (it should be noted that after the start of cooling , and the average cooling rate from the finish ro...

example 2

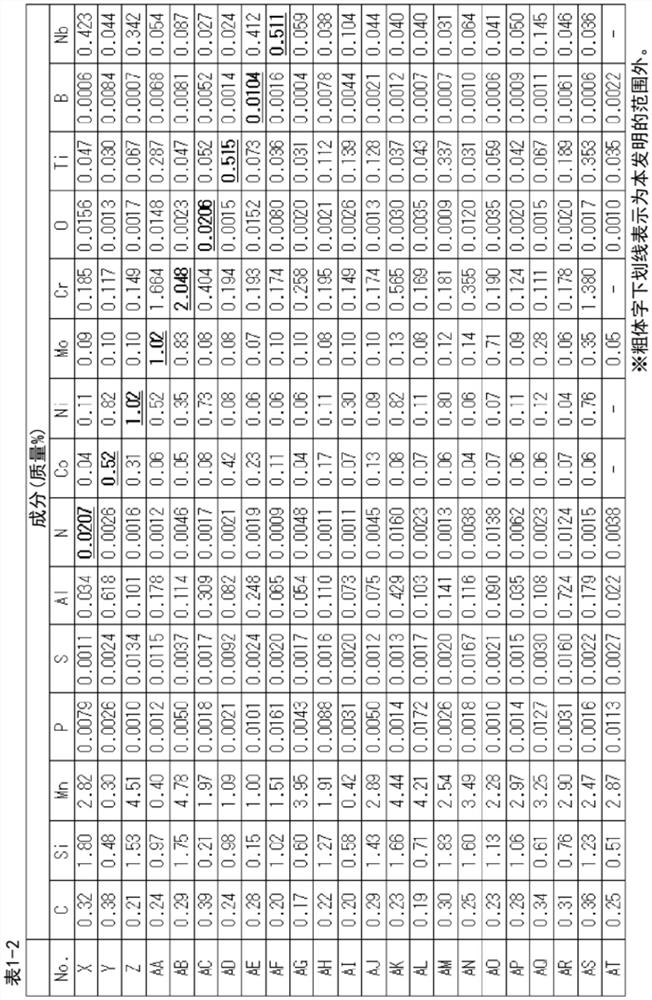

[0311] Furthermore, in order to investigate the influence of the manufacturing conditions, in Table 2, the steel grades A to O, which exhibited excellent properties, were subjected to heat treatment under the manufacturing conditions described in Table 3 to produce hot-rolled steel sheets with a thickness of 2.3 mm. The properties of the steel sheet after cold rolling and annealing were evaluated. Here, the symbols GI and GA of the coating treatment indicate the method of galvanizing treatment. GI is a steel sheet obtained by immersing the steel sheet in a hot-dip galvanizing bath at 460° C. to give a galvanized layer to the surface of the steel sheet. A steel sheet in which an alloy layer of iron and zinc is given to the surface of the steel sheet by raising the temperature of the steel sheet to 485° C. after being immersed in a hot-dip galvanizing bath. In addition, while the steel sheet held at each retention temperature in the cold-rolled sheet annealing is cooled to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com