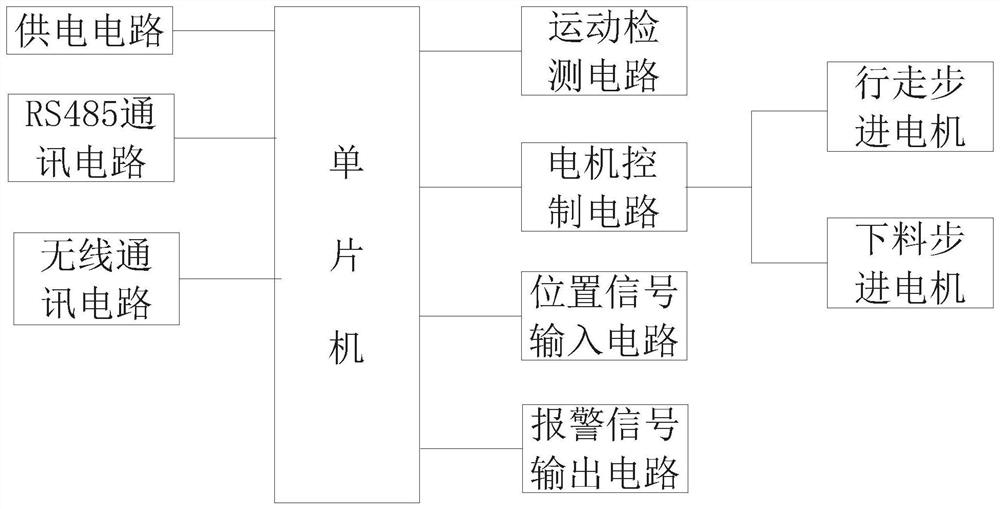

Precise feeding method for poultry house breeding and control system

A control system and precise technology, applied in applications, poultry industry, machine-to-machine/machine-type communication services, etc., can solve the uneven distance between the chute and the discharge port, errors, regional uneven discharge, etc. problem, to achieve the effect of ensuring precise control, precise feeding amount control, and precise feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

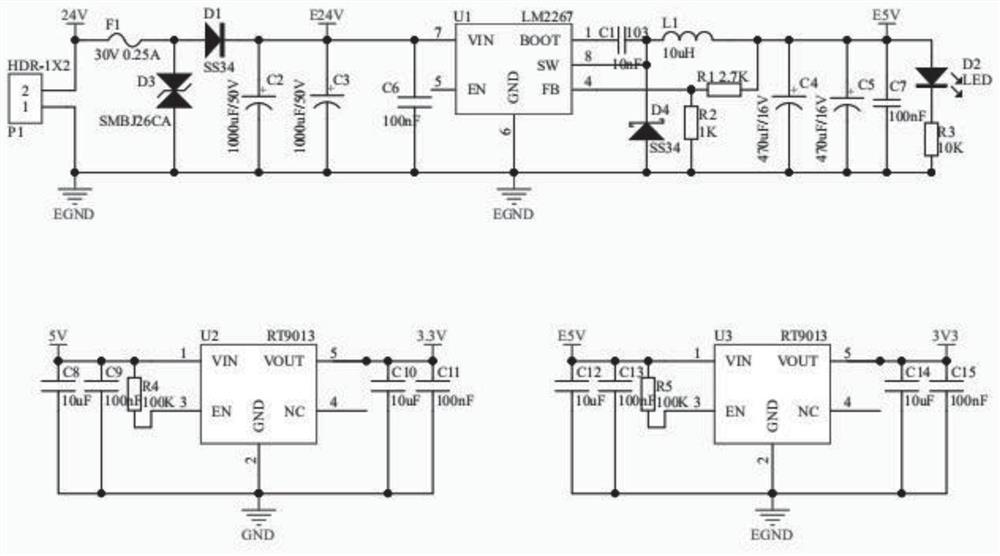

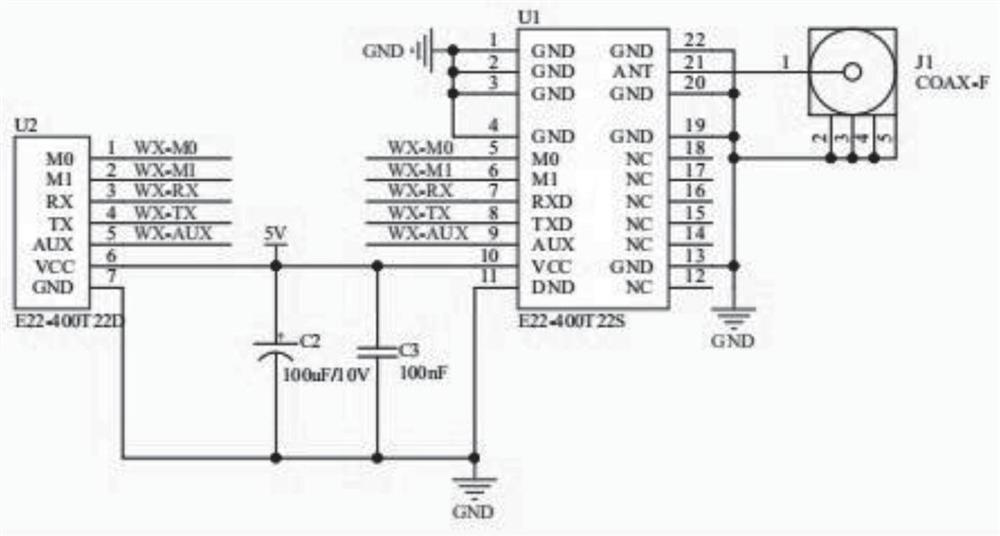

[0041] A precise feeding method for poultry house breeding. According to the number of live poultry in each breeding grid of the cage, the feeding amount in each breeding grid is set, and the walking stepping motor and feeding stepping motor are controlled. The rotating speed makes the walking stepper motor drive the feeding cart to walk at a constant speed, and the feeding stepping motor controls the rotating speed of the auger to control the feeding speed. The same feeding cage is provided with a feeding cart, and the feeding cart is provided with corresponding A hopper of the grid, each of the hoppers is provided with an auger controlled by a separate feeding stepp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com