Resistance welding equipment for battery tabs

A technology of resistance welding and battery tabs, which is applied in resistance welding equipment, welding equipment, battery pack components, etc., can solve problems such as insufficient connection between battery tabs and wires, inability to quickly and stably weld flux, and damage to lithium batteries , to achieve the effect of reducing irregular flow, increasing speed and avoiding explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

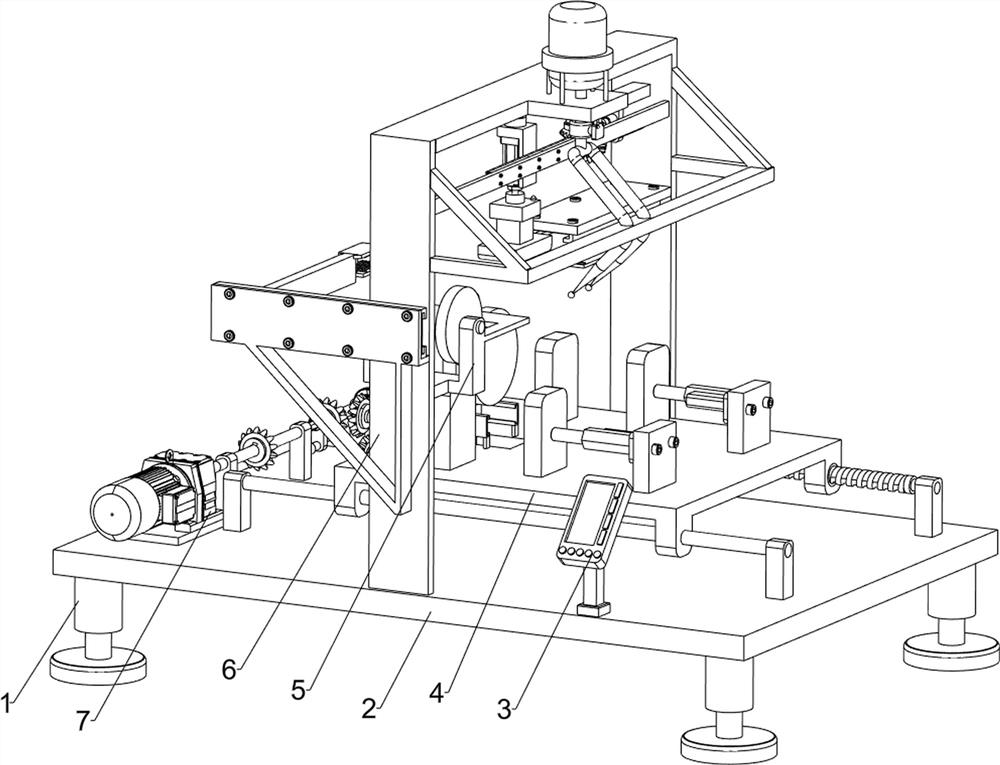

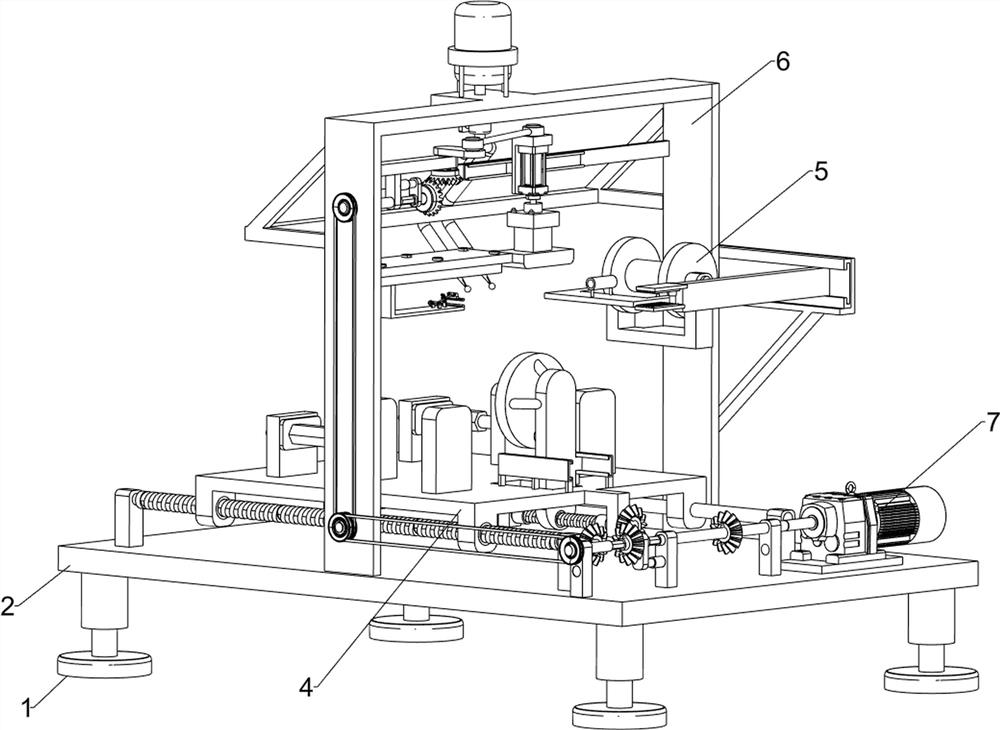

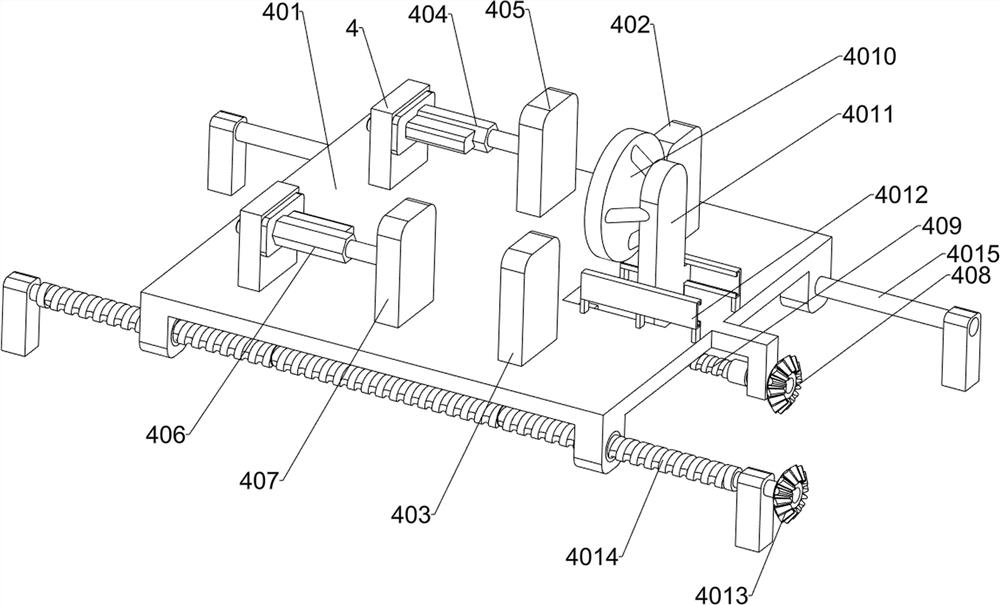

[0033] A resistance welding equipment for battery tabs, such as Figure 1-11 As shown, it includes a base 1, a support base 2, a control panel 3, a fixing system 4, a welding wire pulling positioning system 5, a welding system 6 and a power system 7; four diagonal corners at the bottom of the support base 2 are respectively provided with a set of bases 1; The support base plate 2 is connected with the control panel 3; the support base plate 2 is connected with the fixing system 4; the support base plate 2 is connected with the welding system 6; the support base plate 2 is connected with the power system 7; the welding wire pulling positioning system 5 is connected with the welding system 6 Connection; the welding system 6 is connected with the power system 7.

[0034] Before the device is in operation, place the device on a stable working place, adjust the telescopic height of the base 1, so that the supporting base 2 is in a horizontal state, connect the external power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com