Clamping force controllable air pressure equipment

A controllable, air-pressure technology, applied in chucks, manipulators, manufacturing tools, etc., can solve problems such as gripper freezing and carton falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

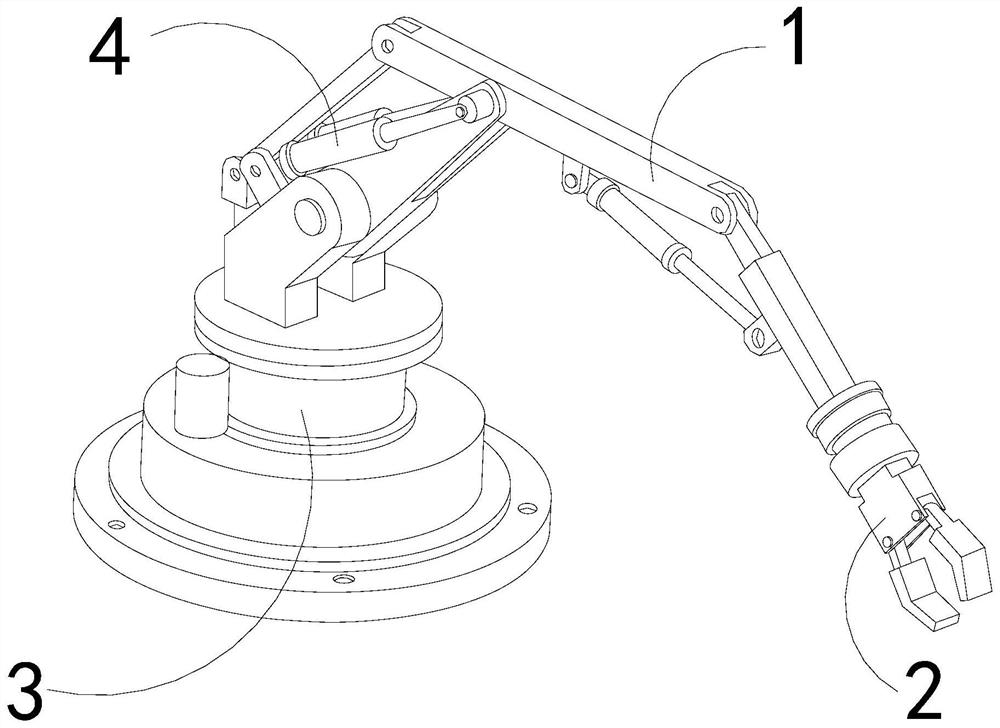

[0026] For example figure 1 -example Figure 5 Shown:

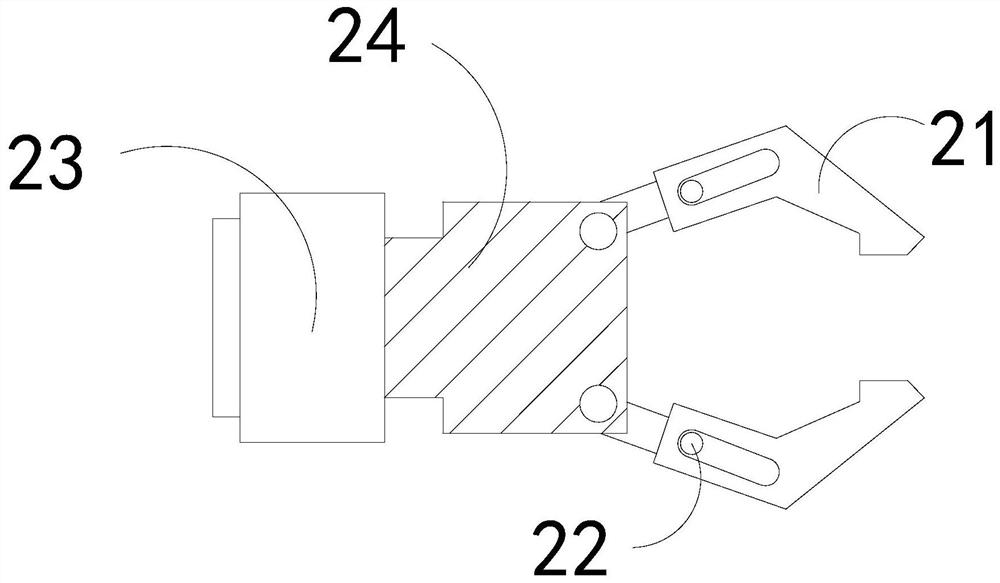

[0027] The present invention provides a pneumatic device with controllable clamping force. Its structure includes a linkage rod 1, a clamper 2, a base 3, and a pneumatic rod 4. 4 is connected to the side of the linkage rod 1, and the holder 2 is installed at the front end of the linkage rod 1; the holder 2 includes a clamping plate 21, a vibrating ball 22, an engaging plate 23, and a connecting plate 24, The clamping plate 21 is movably engaged with the right end of the coupling plate 24 , the vibrating ball 22 is mounted inside the clamping plate 21 , and the coupling plate 24 is embedded in the right side of the connecting plate 23 .

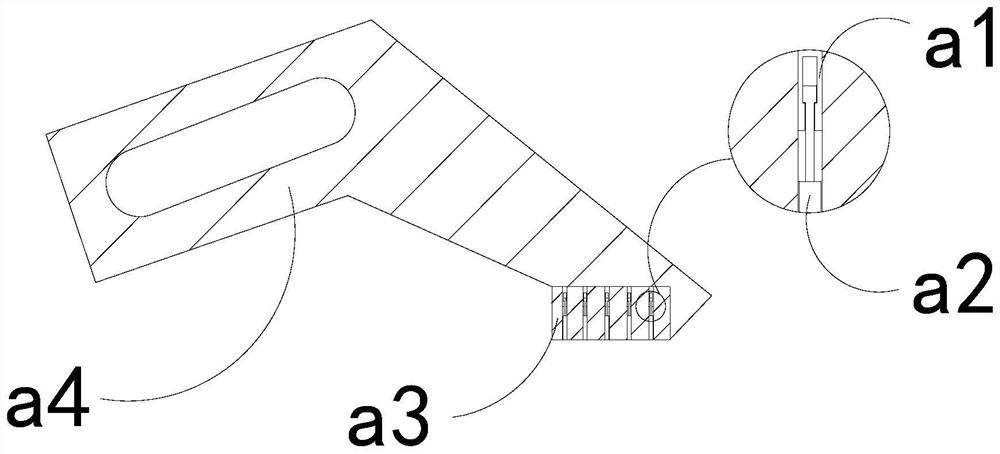

[0028] Wherein, the clamping plate 21 includes a built-in frame a1, a telescopic rod a2, a contact plate a3, and a plate body a4. The built-in frame a1 is embedded in the inner position of the contact plate a3. Movable engagement, the contact plate a3 and the plate body a4 are an integ...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the ice-breaking mechanism b3 includes an outer ring c1, an overhanging block c2, a middle solid block c3, and a connecting rod c4. Installed at the inner center of the outer ring c1, the connecting rod c4 is embedded in the outer surface of the middle solid block c3, and there are four outstretched blocks c2, which are evenly distributed in a circular shape on the outer ring c1 , through the throwing force generated by the rotation of the mechanism, the overhanging block c2 can be extended outward along the outer ring c1, so that the overhanging block c2 can push away the ice surface on the surface of the outer ring c1.

[0036] Wherein, the overhanging block c2 includes a crushing groove c21, a receiving plate c22, an impact block c23, and a bottom plate c24. In combination, the impact block c23 is embedded and fixed on the upper surface of the bottom plate c24, and the crushing groove c21 is in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com