Processing method of environment-friendly foam packaging box

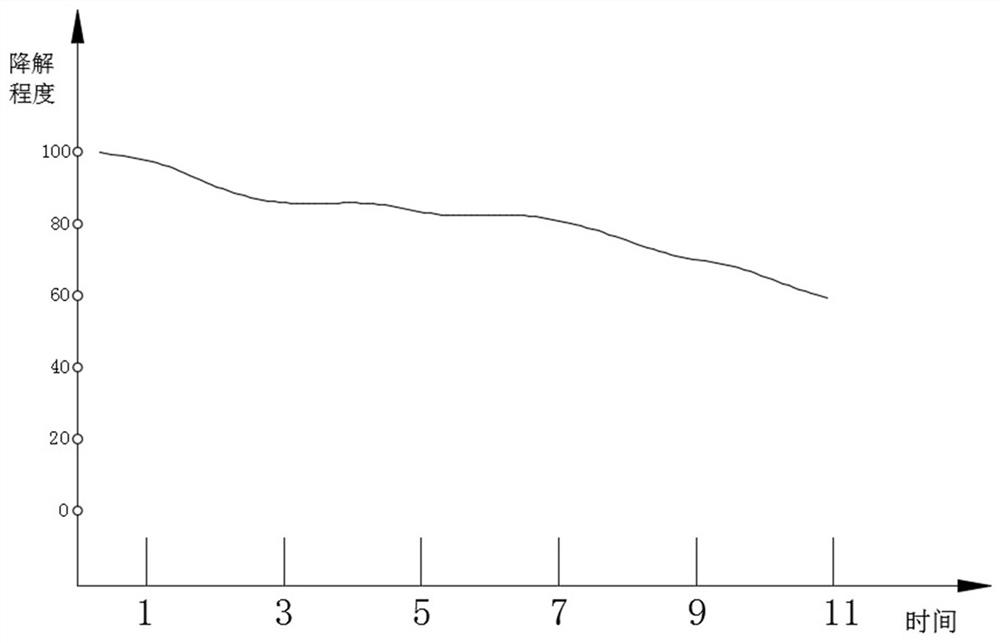

A processing method and packaging box technology, which are applied in the field of foam packaging boxes, can solve the problems of low repeated use rate of foam packaging boxes, reduce heat exchange of foam packaging boxes, increase the number of foam boxes used, etc., so as to improve the repeated use rate and recycling. rate, reduce the amount of use, the effect of small polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

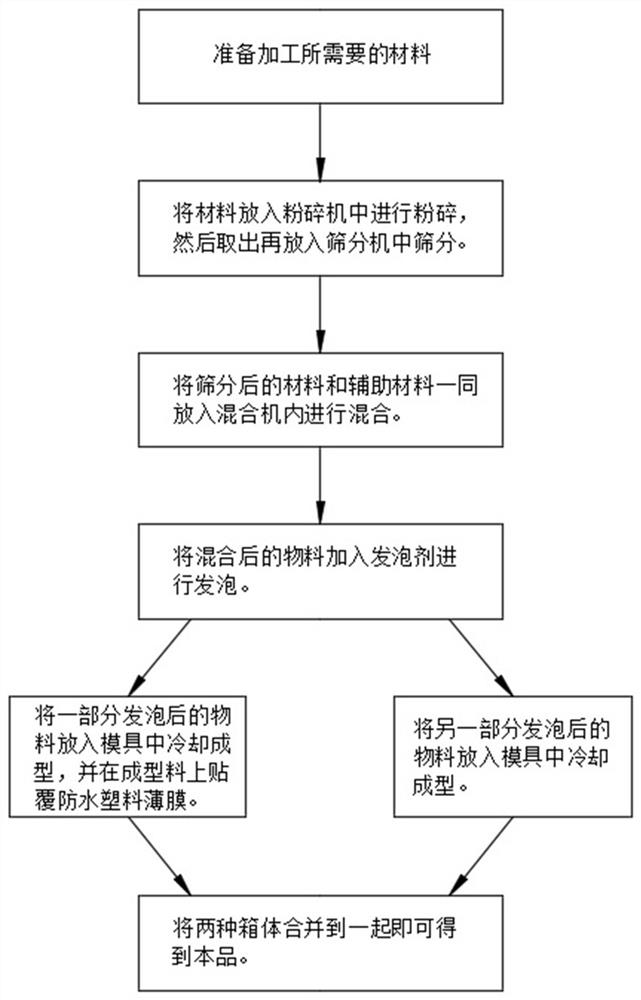

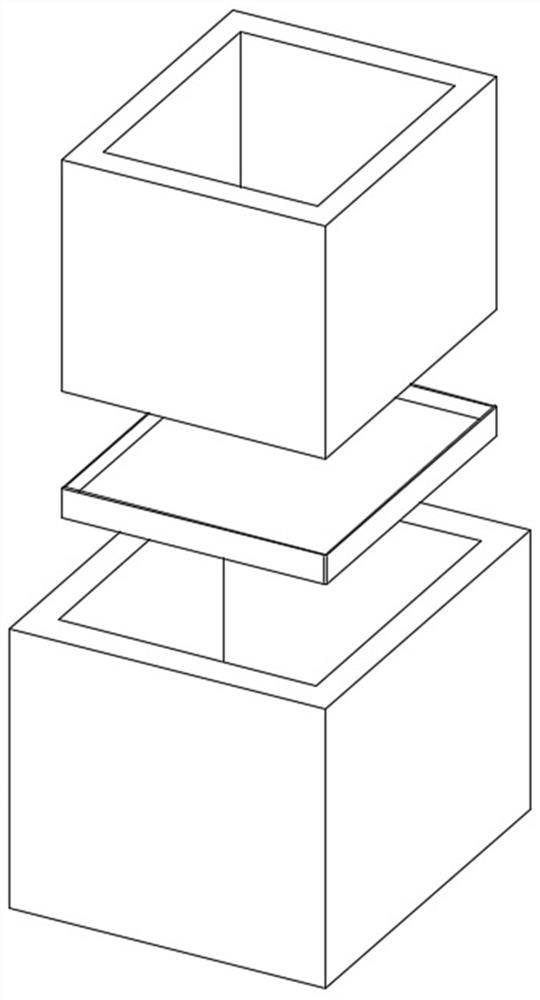

[0031] refer to Figure 1-6 , a processing method of an environment-friendly foam packaging box, the method comprising:

[0032] S1: Weigh the raw materials in the following parts by weight: 50-80 parts of polystyrene granules, 30-50 parts of modified starch, 20-40 parts of strong solvent, 10-20 parts of flame retardant, 20-40 parts of absolute ethanol, 10-30 parts of methyl tert-butyl ether, 10-20 parts of azodicarbonamide;

[0033] S2: Prepare a pulverizer and a sieving machine, put the polystyrene particles described in S1 into the pulverizer for pulverization, put the pulverized polystyrene pulverized material into the sieving machine, and the sieving machine screens materials of different sizes points to obtain crushed polystyrene particles;

[0034] S3: Prepare the mixer, put the crushed polystyrene particles described in S2 into the mixer, and then add the modified starch, strong solvent, flame retardant, absolute ethanol, methyl tert-butyl ether and azo Formamide is...

Embodiment 2

[0046] refer to Figure 1-2 , a processing method of an environment-friendly foam packaging box, the method comprising:

[0047] S1: Weigh the raw materials in the following parts by weight: 50-80 parts of polystyrene granules, 30-50 parts of modified starch, 20-40 parts of strong solvent, 10-20 parts of flame retardant, 20-40 parts of absolute ethanol, 10-30 parts of methyl tert-butyl ether, 10-20 parts of azodicarbonamide;

[0048] S2: Prepare a pulverizer and a sieving machine, put the polystyrene particles described in S1 into the pulverizer for pulverization, put the pulverized polystyrene pulverized material into the sieving machine, and the sieving machine screens materials of different sizes points to obtain crushed polystyrene particles;

[0049] S3: Prepare the mixer, put the crushed polystyrene particles described in S2 into the mixer, and then add the modified starch, strong solvent, flame retardant, absolute ethanol, methyl tert-butyl ether and azo Formamide is p...

Embodiment 3

[0060] refer to Figure 1-2 , a processing method of an environment-friendly foam packaging box, the method comprising:

[0061] S1: Weigh the raw materials in the following parts by weight: 50-80 parts of polystyrene granules, 30-50 parts of modified starch, 20-40 parts of strong solvent, 10-20 parts of flame retardant, 20-40 parts of absolute ethanol, 10-30 parts of methyl tert-butyl ether, 10-20 parts of azodicarbonamide;

[0062] S2: Prepare a pulverizer and a sieving machine, put the polystyrene particles described in S1 into the pulverizer for pulverization, put the pulverized polystyrene pulverized material into the sieving machine, and the sieving machine screens materials of different sizes points to obtain crushed polystyrene particles;

[0063] S3: Prepare the mixer, put the crushed polystyrene particles described in S2 into the mixer, and then add the modified starch, strong solvent, flame retardant, absolute ethanol, methyl tert-butyl ether and azo Formamide is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com