Heat preservation canvas and processing technology thereof

A processing technology and canvas technology, applied in the field of thermal insulation canvas and its processing technology, to achieve the effects of cost reduction, good comfort, and excellent wind and cold resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

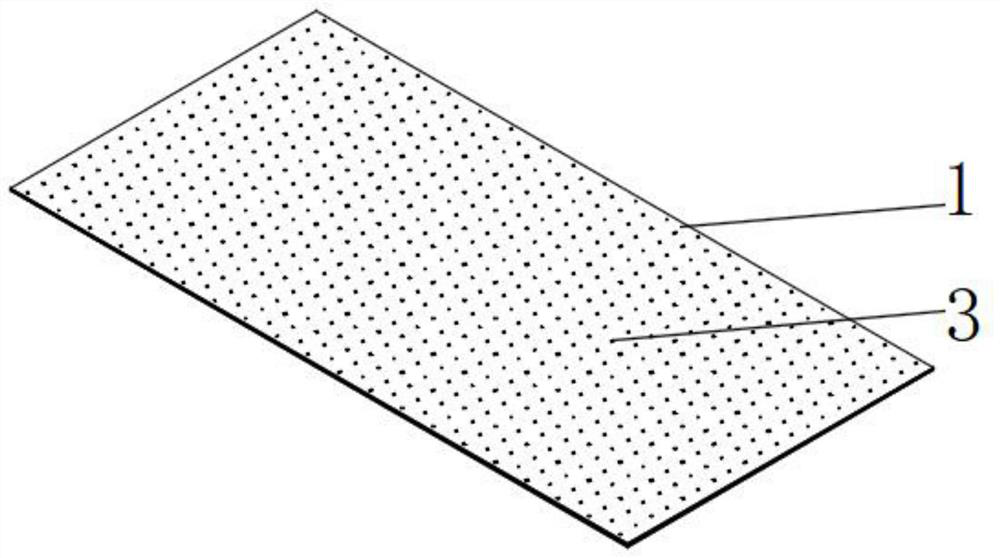

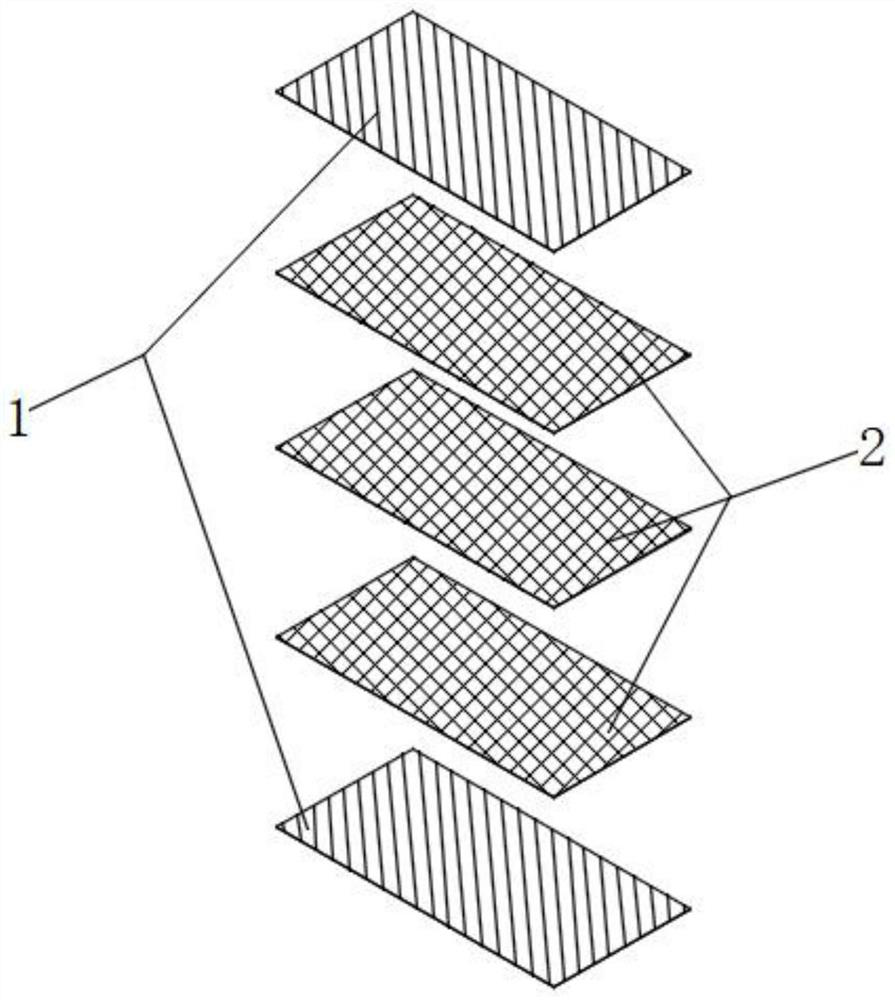

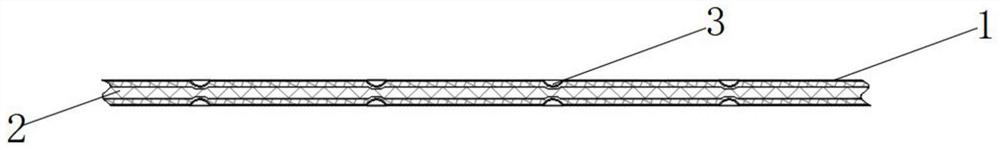

[0038] Combine below Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a thermal insulation canvas and its processing technology, including a waterproof layer 1 and a thermal insulation layer 2, the thermal insulation layer 2 is arranged in multiple layers, and the thermal insulation layer 2 is arranged between the upper and lower waterproof layers 1, The insulation layer 2 and the waterproof layer 1 are fixed by ultrasonic welding.

[0039] Specifically, ultrasonic welding points 3 are provided in the array of welded and fixed positions of the insulation layer 2 and the waterproof layer 1 .

[0040] Specifically, the density interval of the ultrasonic welding points 3 is not greater than 15mm.

[0041] Specifically, the waterproof layer 1 is made of composite flame-retardant polyester fabric, and the insulation layer 2 is made of high-molecular thermal insulation and moisture resistance cotton.

[0042] Specifically, the polymer thermal insula...

specific Embodiment 2

[0044] A processing technology for thermal insulation canvas, comprising the steps of:

[0045] Sp1: Spinning of insulation layer 2, blending nomex fiber with cotton fiber;

[0046] Sp1-1: Opening and mixing of raw materials, nomex fiber and cotton fiber contain less impurities, and three opening and mixing can be directly used to loosen and mix the two fiber raw materials as much as possible to form a lap or loose Cotton, and need to prevent fiber damage;

[0047]Sp1-2: Carding, after opening and cleaning, the fibers in the laps or loose cotton are mostly in the state of loose cotton blocks and cotton bundles, containing some small, highly adhesive fibrous impurities, using roller combing The cotton machine combs the small cotton bundles into a single fiber state by means of the movement of the needle surface, so that the fibers are straightened in parallel and made into a uniform sliver;

[0048] Sp1-3: Draw frame and roving, feed 6-8 cotton slivers together into the draw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com