Jacket transportation and installation system

An installation system and jacket technology, which are applied in the directions of transportation and packaging, cargo handling equipment, ships, etc., can solve the problems of increasing the transportation and installation cost of the jacket, unfavorable for efficient transportation of the jacket, and high equipment requirements. The effect of reducing transportation and installation costs and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

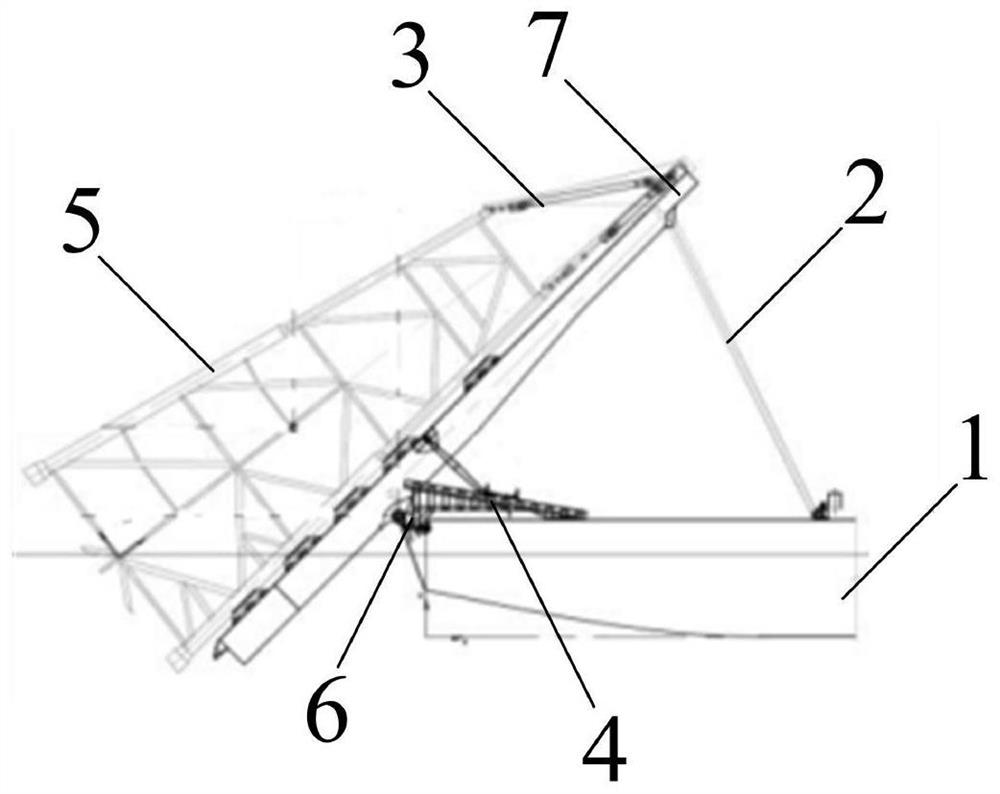

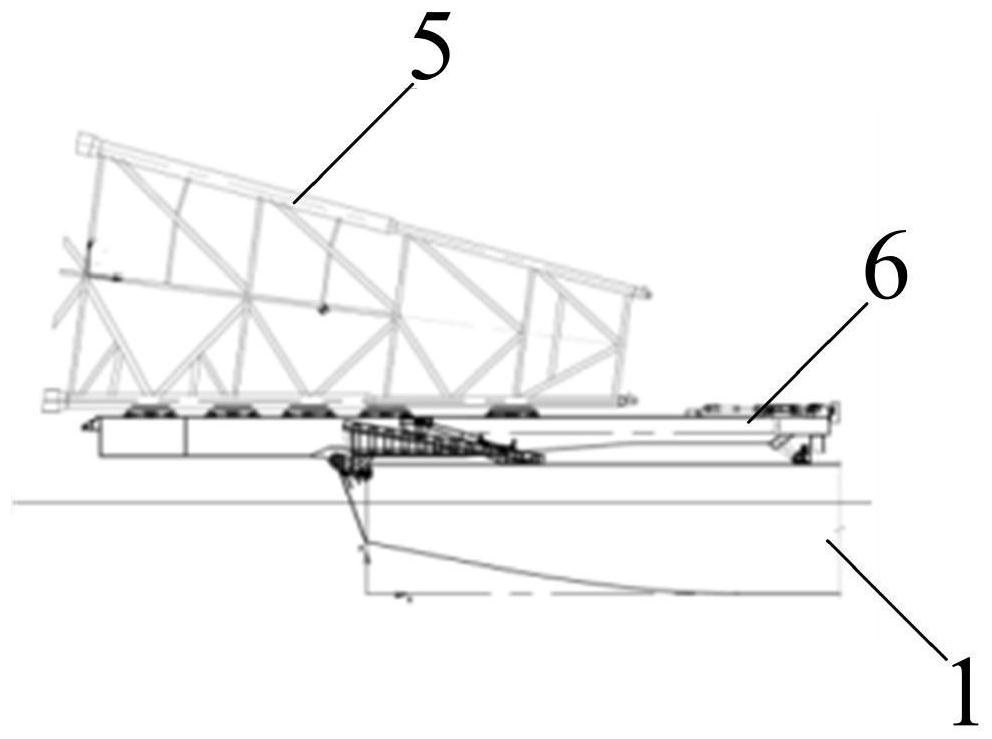

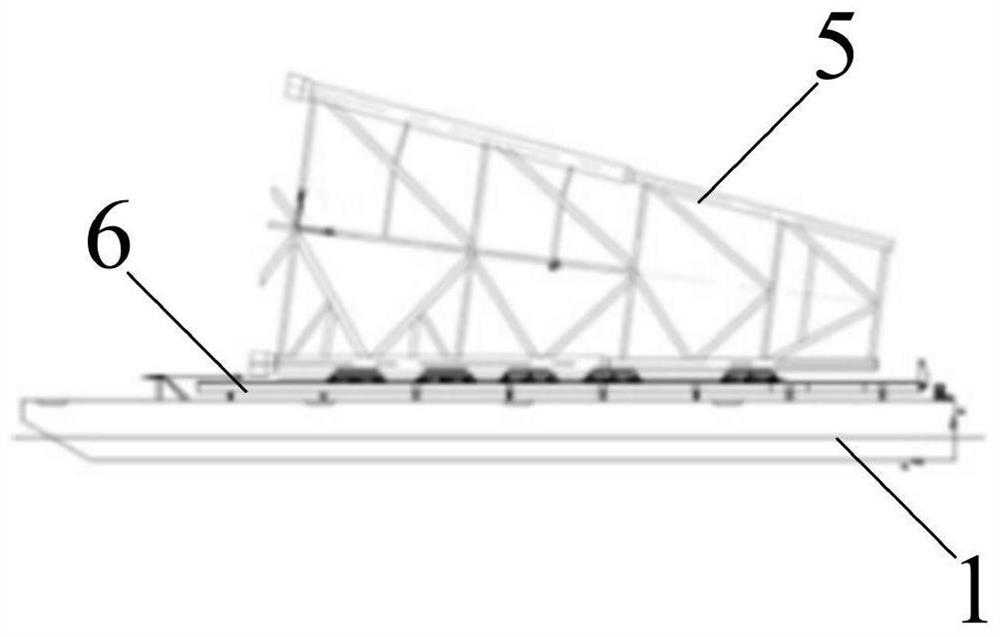

[0028] as attached figure 1 to attach Figure 6 shown

[0029] The present invention provides a jacket transport and installation system, which includes a barge body 1, a pitch luffing system 2, a steel strand 3, a main boom jacking system 4, a jacket body 5, a lateral sliding system 6 and a pitch main boom 7, The lateral sliding system 6 is installed above the barge body 1; the pitching main arm 7 is installed on one side above the lateral sliding system 6, and the pitching main arm 7 is inclined; the jacket body 5 is installed on the pitching main arm On the arm 7; the upper end of the pitch luffing system 2 is connected with the lower upper end of the pitching main arm 7, and the lower end of the pitching luffing system 2 is connected with the end of the lateral sliding system 6 away from the pitching main arm 7; the main arm jacking system 4 Installed at the junction of the pitching main arm 7 and the lateral sliding system 6, and the upper end of the main arm jacking sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com