Papermaking sewage air flotation treatment equipment

A technology for papermaking sewage and treatment equipment, which is applied in flotation water/sewage treatment, water/sludge/sewage treatment, sludge treatment, etc. It can solve the problems affecting the scraping efficiency and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

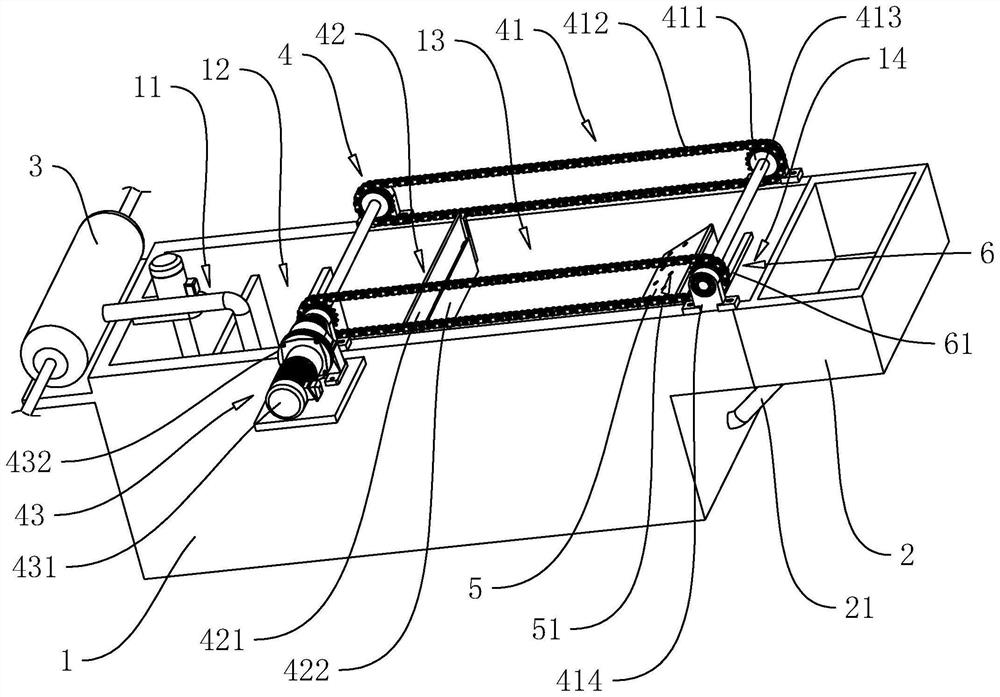

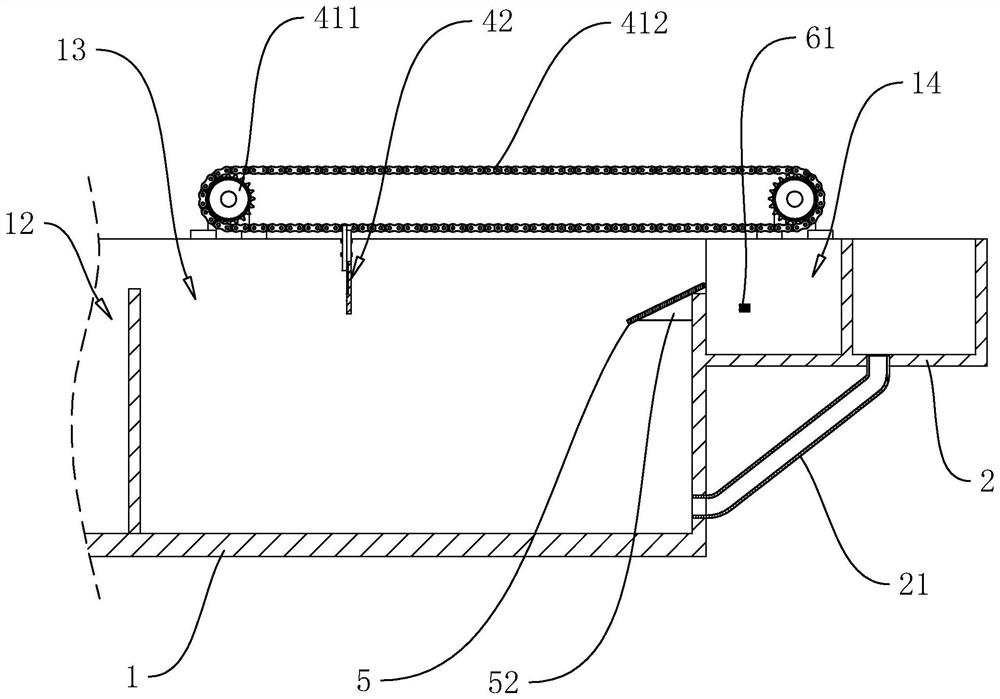

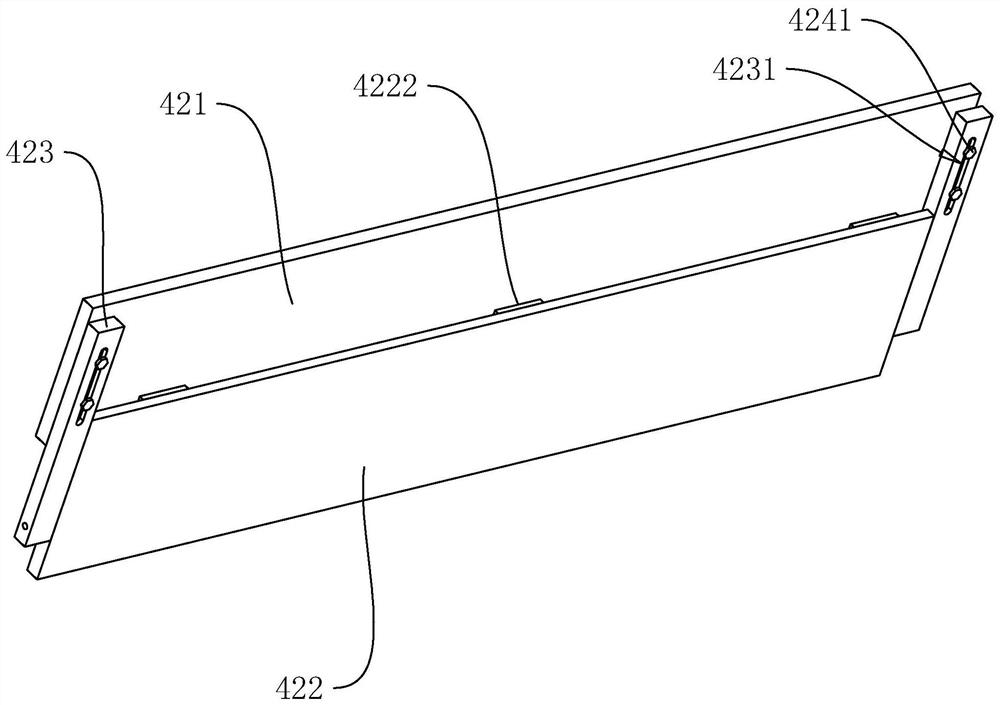

[0036] The following is attached Figure 1-6 Application for further details.

[0037] The embodiment of the application discloses an air flotation treatment equipment for papermaking sewage. refer to figure 1 The air flotation treatment equipment for papermaking wastewater includes a dissolved air tank 3, an air flotation tank 1 and a clear water tank 2. The air flotation tank 1 is provided with a reaction zone 11, a contact zone 12, a separation zone 13 and a sludge zone 14. The upper part of the air flotation tank 1 is provided with Slag scraping device 4; sewage enters the air flotation reaction zone 11 for flocculation reaction and then enters the air flotation contact zone 12. In the contact zone 12, the microbubbles in the dissolved air water from the dissolved air tank 3 adhere to the flocculated suspended matter and enter together In the separation zone 13, the flocs and air bubbles rise to the liquid surface together to form scum;

[0038] refer to figure 1 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com