Large-wall-thickness X70-grade anti-acid pipeline steel and preparation method thereof

A pipeline steel, content technology, applied in the field of hot-rolled pipeline steel, can solve the problems of consumption and increase the cost of pipeline steel, and achieve the effects of simple process, fine grain size, and guaranteed low temperature toughness and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An X70-grade acid-resistant pipeline steel with a large wall thickness according to an embodiment of the present invention includes the following components in weight percent, C: 0.039wt%, Si: 0.26wt%, Mn: 1.10wt%, P0.0043wt%, S0.0025wt% %, Cr: 0.25wt%, Ti: 0.012wt%, Nb: 0.059wt%, V: 0.043wt%, Mg: 0.003wt%, others are Fe and unavoidable trace impurities.

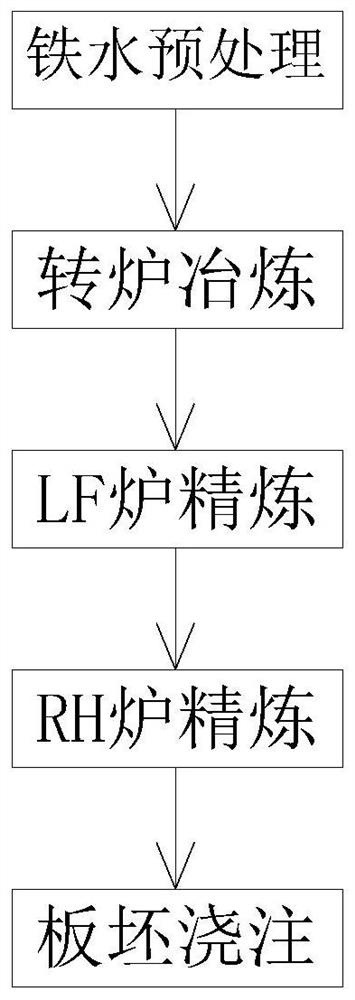

[0032] See attached figure 1 Shown, preparation method shown in the present invention comprises:

[0033] (1) Hot metal pretreatment, respectively carry out desulfurization, dephosphorization and desiliconization treatment to hot metal, so that the S content in the hot metal is 0.05%, the Si content is reduced to not higher than 0.2wt%, and the P content is reduced to not higher than 0.01wt% %;

[0034] (2) Converter smelting. Converter smelting adopts top blowing and bottom stirring at the same time, adopts slag blocking operation to prevent phosphorus return when tapping, and controls carbon content to be no more ...

Embodiment 2

[0046] A large wall thickness X70 grade acid-resistant pipeline steel in this embodiment, including C: 0.045wt%, Si: 0.28wt%, Mn: 1.11wt%, P0.0045wt%, S0.0026wt%, Cr: 0.26wt% , Ti:0.016wt%, Nb:0.066wt%, V:0.042wt%, Mg:0.003wt%, others are Fe and unavoidable trace impurities.

[0047] See attached figure 1 Shown, preparation method shown in the present invention comprises:

[0048] (1) Hot metal pretreatment, respectively carry out desulfurization, dephosphorization and desiliconization treatment to hot metal, make the S content w in the hot metal be 0.05%, the Si content is reduced to not higher than 0.2wt%, the P content is reduced to not higher than 0.01 wt%;

[0049] (2) Converter smelting. Converter smelting adopts top blowing and bottom stirring at the same time, and adopts slag blocking operation to prevent phosphorus back when tapping, and controls the carbon content to 0.027wt%, and the P content to 0.0038wt%;

[0050] (3) Refining in LF furnace, using silicon-calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com