A kind of preparation method of cage multilayer structure boron doped diamond electrode

A diamond electrode, multi-layer structure technology, applied in the direction of chemical instruments and methods, coating, lamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

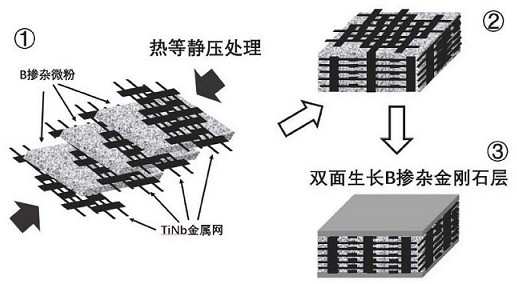

[0031] Firstly, TiNb metal mesh and boron-doped diamond powder with particle size of 50 μm were placed alternately layer by layer. Diamond powder and TiNb metal mesh were processed by high temperature and high pressure molding under the conditions of pressure of 200 MPa and temperature of 1200 °C for 3 h. Then, a boron-doped diamond protective layer is deposited on the composite electrode by microwave plasma chemical vapor deposition technology to enhance the strength of the diamond electrode with multi-channel sandwich structure. Make sure that the deposition temperature is around 780°C. Using CH 4 / H 2 nucleation in an atmosphere with a flow ratio of 7% for 2 h, followed by the reduction of CH 4 Ratio to CH 4 / H 2 The flow ratio is 5% for diamond growth, and the carrier H of the boron source is introduced at the same time 2 Gas flow as a percentage of total H 2 The proportion of gas flow is 5%. And the lower surface of the composite electrode is again realized by the...

Embodiment 2

[0033] Firstly, TiNb metal mesh and boron-doped diamond powder with particle size of 100 μm were alternately placed layer by layer. The diamond powder and the TiNb metal mesh were processed by high temperature and high pressure molding at a pressure of 300 MPa and a temperature of 1300 °C for 4 h. Then, a boron-doped diamond protective layer is deposited on the composite electrode by microwave plasma chemical vapor deposition technology to enhance the strength of the diamond electrode with multi-channel sandwich structure. Make sure that the deposition temperature is around 820°C. in CH 4 / H 2 nucleation in an atmosphere with a flow ratio of 9% for 1 h, followed by the reduction of CH 4 Ratio to CH 4 / H 2 The flow ratio is 3% for diamond growth, and the carrier H of the boron source is introduced at the same time 2 Gas flow as a percentage of total H 2 The proportion of gas flow is 5%. And the lower surface of the composite electrode is again realized by the above proc...

Embodiment 3

[0035] First, the TiNb metal mesh and boron-doped diamond powder with a particle size of 1 μm were alternately placed layer by layer. The diamond powder mixed with the pre-graphite powder and the TiNb metal mesh were processed by high temperature and high pressure molding at a pressure of 150 MPa and a temperature of 1000 °C for 5 h. Then, a boron-doped diamond protection layer is deposited on the composite electrode by DC arc plasma chemical vapor deposition technology to enhance the strength of the diamond electrode with multi-channel sandwich structure. Make sure that the deposition temperature is around 800°C. in CH 4 / H 2 nucleation in an atmosphere with a flow ratio of 7% for 2 h, followed by the reduction of CH 4 Ratio to CH 4 / H 2 The flow ratio is 5% for diamond growth, and the carrier H of the boron source is introduced at the same time 2 Gas flow as a percentage of total H 2 The proportion of gas flow is 10%. And the lower surface of the composite electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com