Dip dyeing process for asphalt on surface of waterproof roll

A waterproof membrane and asphalt technology, which is applied to the surface coating liquid device, surface pretreatment, textiles and papermaking, etc., can solve the problem of low tensile strength of asphalt waterproof membrane, low tear strength and uniform asphalt on the surface In order to improve the waterproof effect, improve the bonding and pressing effect, and ensure the normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

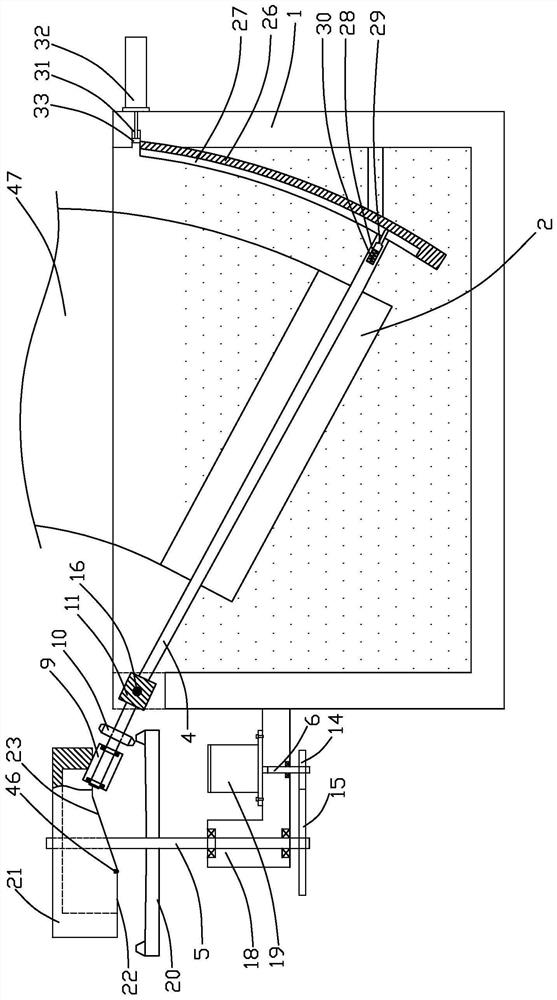

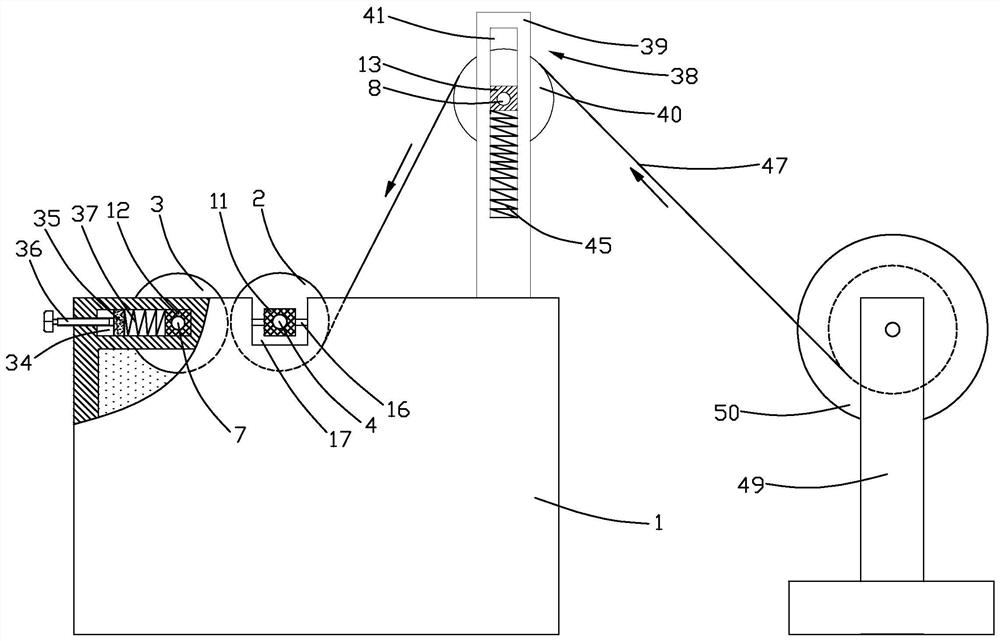

[0029] The following is attached Figure 1-5 The application is described in further detail.

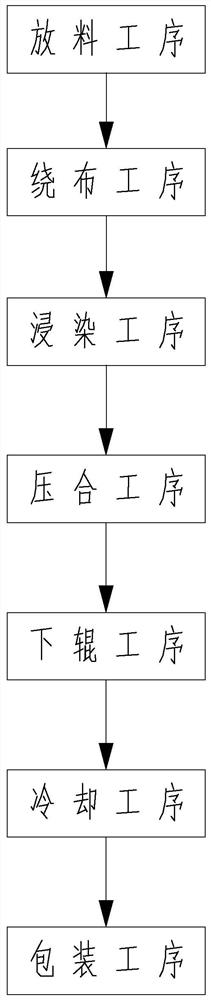

[0030] refer to figure 1 with Figure 5 , the embodiment of the present invention discloses a dip-dyeing process of asphalt on the surface of a waterproof membrane, comprising the following process steps:

[0031] S1, the feeding process, the cloth coil 50 wound with the tire base cloth 47 is rotated and installed on the coil bracket 49, and the outer end of the tire base cloth 47 is drawn from the cloth coil 50 to bypass the upper part of the pre-tensioner wheel, And be fixed on the roller surface of dip coating roller 2;

[0032] S2, the cloth wrapping process, the asphalt paint used for dipping the tire base cloth 47 is filled in the dipping pool 1, and the asphalt paint is made of the following raw materials in parts by weight: 80-90 parts of No. 60 asphalt, 10-16 parts of mineral Oil, 20-25 parts of styrene thermoplastic elastomer and 15-25 parts of reinforcing agent. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com